GMP Compliance in Patient-Specific Stem Cell Therapies: From Foundational Principles to Commercial Manufacturing

This article provides a comprehensive guide to Good Manufacturing Practice (GMP) compliance for researchers and drug development professionals navigating the complex transition from laboratory research to clinical manufacturing of patient-specific...

GMP Compliance in Patient-Specific Stem Cell Therapies: From Foundational Principles to Commercial Manufacturing

Abstract

This article provides a comprehensive guide to Good Manufacturing Practice (GMP) compliance for researchers and drug development professionals navigating the complex transition from laboratory research to clinical manufacturing of patient-specific stem cell therapies. Covering foundational ethical principles and regulatory frameworks, the content details practical methodologies for facility design, quality systems, and process automation. It addresses critical troubleshooting strategies for donor variability and process transfer challenges, while outlining phase-appropriate validation approaches for analytical methods and product characterization. With the global cell and gene therapy market projected to reach $97 billion by 2033, this resource offers essential insights for developing compliant, scalable manufacturing processes that ensure patient safety and therapeutic efficacy.

Ethical Foundations and Regulatory Frameworks for Stem Cell Therapy Manufacturing

The translation of patient-specific stem cell therapies from research to clinical application is guided by a framework of core ethical principles. Rigor, oversight, and transparency are not merely ancillary concerns but foundational requirements for ensuring scientific integrity, patient safety, and public trust in Advanced Therapy Medicinal Products (ATMPs) [1] [2]. These principles are operationalized through adherence to Good Manufacturing Practice (GMP), which provides a quality assurance system for the entire manufacturing process [3]. This document outlines practical application notes and protocols for integrating these ethical pillars into the GMP-compliant development of patient-specific stem cell therapies, providing a roadmap for researchers, scientists, and drug development professionals.

Foundational Ethical Principles

The International Society for Stem Cell Research (ISSCR) guidelines establish a set of widely shared ethical principles for stem cell research and clinical translation [1] [4]. These principles form the ethical bedrock upon which specific manufacturing protocols are built.

- Integrity of the Research Enterprise: The primary goals are to advance scientific understanding and generate robust evidence for addressing unmet medical needs. This requires independent peer review, oversight, and accountability at every stage, from basic research to clinical trials [1] [4].

- Primacy of Patient Welfare: The welfare of patients and research subjects is paramount. This principle mandates that clinical testing must never allow the promise for future patients to override the welfare of current research subjects [1] [4]. Providing unproven stem cell-based interventions outside of formal, regulated research settings is a breach of professional ethics [1] [2].

- Respect for Patients and Research Subjects: Researchers and clinicians must empower potential research participants to exercise valid informed consent. Patients must be accurately informed about the risks and the current state of evidence for novel interventions [1] [4].

- Transparency: Researchers must promote the timely exchange of accurate scientific information, including the publication of both positive and negative results. This extends to communicating with patient communities and the public about the state of the art, including uncertainties [1] [4].

- Social and Distributive Justice: The benefits of clinical translation should be distributed justly and globally. This includes addressing unmet medical needs, ensuring fair subject selection in clinical trials, and working to make new therapies accessible [1] [4].

Application of Ethical Principles in GMP Manufacturing

The ethical principles of rigor, oversight, and transparency are implemented through specific, actionable GMP standards in the manufacturing process for patient-specific stem cell therapies.

Rigor in Process and Analytics

Rigor is demonstrated through validated, reproducible manufacturing processes and analytical methods. This ensures that every product batch meets pre-defined quality attributes, which is critical for patient safety and product efficacy.

Table 1: Key Quality Attributes and Validated Analytical Methods for hiPSC Manufacturing

| Quality Attribute | Validated Analytical Method | Key Validation Parameters | Importance for Patient-Specific Therapies |

|---|---|---|---|

| Viable Cell Count | Automated image cytometer (e.g., NucleoCounter NC-100) [5] | Specificity, linearity, accuracy, precision (intra-/inter-operator reproducibility) [5] | Ensures accurate dosing; reflects manufacturing process robustness [5] |

| Cell Identity/Purity | Flow Cytometry | Specificity, accuracy, precision | Confirms the presence of target cell types and absence of unintended lineages (e.g., residual pluripotent cells) |

| Potency | Cell-specific functional assay (e.g., enzymatic activity, in vivo model) [6] | Specificity, linearity, range, accuracy | Measures the biological activity critical for the intended therapeutic effect |

| Sterility | Microbial culture & Mycoplasma testing | Specificity, limit of detection | Ensures the product is free from microbial contamination |

Oversight Through Defined Workflows and Controls

Oversight is embedded into the manufacturing workflow through institutional review, regulatory compliance, and multiple in-process control (IPC) checkpoints. A specialized Embryo Research Oversight (EMRO) process is required for research involving human embryos or the generation of sensitive models like stem cell-based embryo models (SCBEMs) [1] [2]. The ISSCR explicitly prohibits the transplantation of SCBEMs into a uterus or their culture to the point of potential viability (ectogenesis) [1] [7].

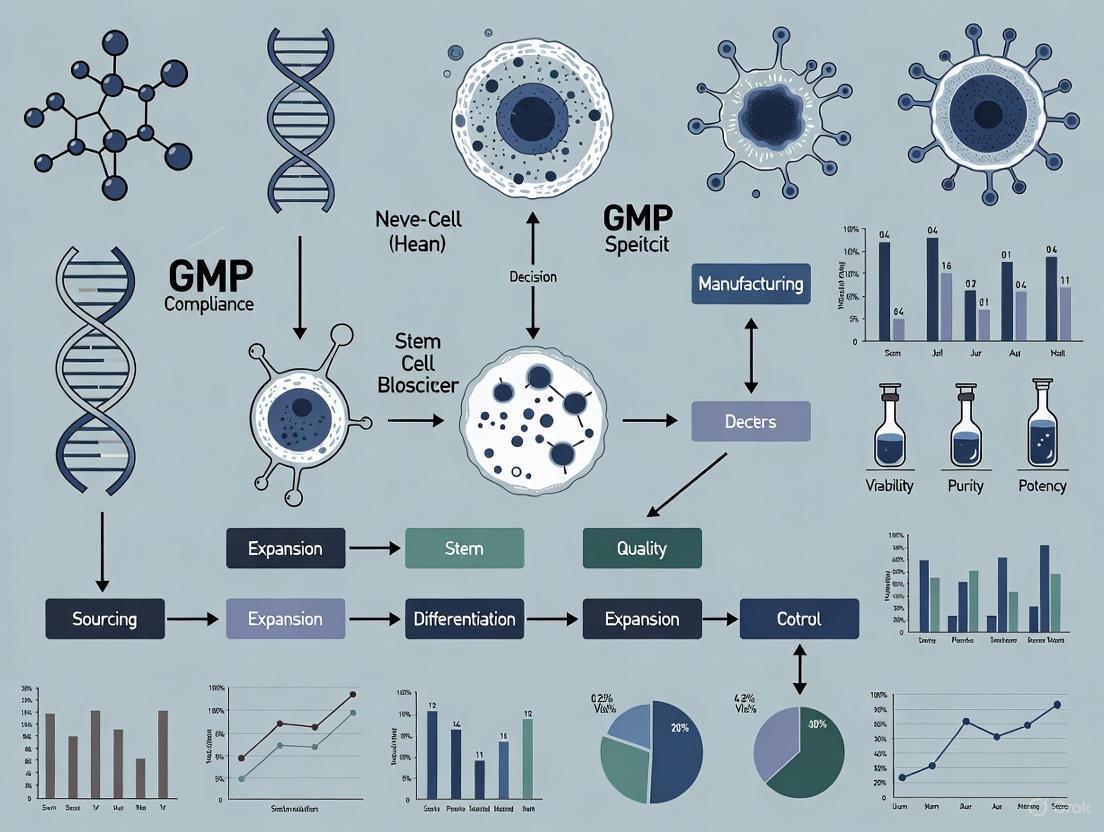

The following workflow diagram illustrates the integration of ethical and GMP oversight points in a typical autologous cell therapy manufacturing process, from patient material collection to product release.

Transparency in Documentation and Reporting

Transparency is maintained through comprehensive and traceable documentation, which is a cornerstone of GMP. This includes:

- Batch Records: Detailed, step-by-step documentation of the entire manufacturing process for each patient-specific batch [3].

- Raw Material Traceability: Full traceability of all reagents and raw materials, including their sourcing and quality testing [3].

- Deviation and Incident Reporting: A system for documenting and investigating any deviation from established procedures [3].

- Data Sharing: Commitment to publishing clinical trial results, regardless of outcome, to contribute to the collective scientific knowledge [1] [4].

Experimental Protocols

Protocol: Validation of an Automated Viable Cell Counting Method for hiPSCs

This protocol is critical for ensuring rigor in a key quality control test during the GMP manufacturing of human induced pluripotent stem cells (hiPSCs), a common starting material for patient-specific therapies [5].

1.0 Objective: To validate an automated viable cell counting method (e.g., NucleoCounter NC-100) for specificity, linearity, range, accuracy, and precision in accordance with ICH Q2(R1) and EudraLex cGMP guidelines [5].

2.0 Materials:

- hiPSC Culture: A well-characterized hiPSC line, maintained under defined conditions.

- Automated Cell Counter: NucleoCounter NC-100 or equivalent.

- Reagents: Proprietary cassettes with immobilized Propidium Iodide (PI).

- Reference Method Instrument: Flow cytometer.

3.0 Methodology:

- 3.1 Sample Preparation: Generate hiPSC samples with a wide range of viabilities (e.g., 50-95%). This can be achieved by subjecting cells to various stress conditions (e.g., heat, nutrient deprivation).

- 3.2 Specificity: Demonstrate that the method can specifically distinguish between viable and non-viable cells via PI staining, which is incorporated only by permeabilized (dead) cells.

- 3.3 Linearity and Range: Serially dilute samples of known high viability and measure the viable cell concentration with the automated counter. The method's range of reliability is established where results show a linear relationship (R² > 0.98) with expected concentrations [5].

- 3.4 Accuracy: Compare the viable cell count results from the automated method against the results from the reference method (flow cytometry) for the same set of samples. The mean difference should be within pre-defined acceptance criteria (e.g., <10%).

- 3.5 Precision:

- Intra-operator precision: A single analyst performs multiple counts on the same sample.

- Inter-operator precision: Different qualified analysts perform counts on the same sample set. The relative standard deviation (RSD) for both should be within acceptable limits (e.g., <15%).

4.0 Data Analysis: The validation report must include all raw data, calculations for linearity, accuracy, and precision, and a conclusion on the method's suitability for its intended use in GMP manufacturing.

Protocol: Stability Study of Leukapheresis Product for Autologous Therapy

This protocol ensures oversight and rigor in handling the patient's starting material, which is critical for the success of autologous therapies like CAR-T cells [8].

1.0 Objective: To define the optimal storage conditions and maximum hold time for a leukapheresis product (LP) prior to the initiation of manufacturing.

2.0 Materials:

- Leukapheresis Products: Fresh LPs from healthy donors or patients.

- Storage Equipment: Temperature-monitored refrigerators (2-8°C) and room temperature (15-25°C) environments.

- Analytical Equipment: Flow cytometer, automated cell counter.

3.0 Methodology:

- 3.1 Storage: Aliquot a single LP and store portions at both cool temperature (CT: 2-8°C) and room temperature (RT: 15-25°C).

- 3.2 Sampling: Collect samples from each condition at defined timepoints (e.g., 0, 25, 49, 73, 121 hours).

- 3.3 Testing: At each timepoint, assess:

- Viability: Percentage of viable CD45+ leukocytes, CD3+ T cells, CD4+ T cells, CD8+ T cells, etc., using flow cytometry with a viability dye.

- Cell Composition: Frequencies of key leukocyte subpopulations (monocytes, B cells, T cells, NK cells).

- Appearance: Visual inspection for color change or aggregation.

- 3.4 Acceptance Criteria: Stability is defined as the time during which average viability for critical cell types remains ≥90% and cell composition remains consistent without statistically significant change from baseline (T0) [8].

4.0 Data Analysis: Plot viability and cell composition data over time for both storage conditions. The maximum hold time is determined by the latest timepoint where all acceptance criteria are met. Data from one study indicated stability for at least 25 hours at RT and 73 hours at CT [8].

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for GMP-Compliant Stem Cell Therapy Manufacturing

| Reagent/Material | Function | GMP Considerations |

|---|---|---|

| StemRNA Clinical Seed iPSCs [9] | A standardized, clonal master hiPSC line used as a starting material for deriving therapeutic cells. | Submission of a Drug Master File (DMF) to regulators provides comprehensive data on donor screening, GMP manufacturing, and quality controls, streamlining IND filings [9]. |

| Lentiviral Vector [6] [8] | A vector for the stable introduction of a therapeutic transgene (e.g., a corrective gene or CAR) into patient cells. | The manufacturing process must be GMP-compliant. The vector must be tested for safety (e.g., replication-competent lentivirus, sterility, potency) [6]. |

| Transduction Enhancers (LentiBOOST, Protamine Sulfate) [6] | Chemicals that improve the efficiency of lentiviral transduction. | Reducing the quantity of costly viral vector required while maintaining high transduction efficiency. Must be qualified for GMP use [6]. |

| Cell Separation Reagents (e.g., CD4/CD8 Enrichment) [8] | To isolate specific cell populations (e.g., T cells) from a leukapheresis product for further processing. | Use of closed-system, GMP-grade reagents and equipment (e.g., CliniMACS) is required to ensure sterility and process consistency [8]. |

| Validated Cell Culture Media | To support the growth and maintenance of stem cells or their derivatives. | Must be xeno-free or chemically defined where possible. Sourced from qualified suppliers with full traceability and certificate of analysis [5] [3]. |

The path to delivering safe and effective patient-specific stem cell therapies is inextricably linked to the steadfast application of the ethical principles of rigor, oversight, and transparency. These principles are given practical form through stringent GMP compliance, which governs every facet of manufacturing—from the quality of the starting materials and the validation of analytical methods to the comprehensive documentation of the process. As the field advances with emerging technologies, such as complex stem cell-based embryo models, a proactive and adaptive ethical and regulatory framework, as exemplified by the updated ISSCR guidelines, is essential [1] [7]. By embedding these core principles into their work, researchers and drug developers can ensure the scientific integrity of their products, uphold the highest standards of patient welfare, and maintain the public trust necessary for the continued progress of regenerative medicine.

For developers of patient-specific stem cell therapies, navigating the U.S. regulatory landscape is a critical component of translational research. The Center for Biologics Evaluation and Research (CBER) within the FDA regulates biological products, including cell and gene therapy products, under the Federal Food, Drug and Cosmetic Act and the Public Health Service Act [10]. These therapies are classified as Advanced Therapy Medicinal Products (ATMPs) and must adhere to a rigorous framework to ensure patient safety, product quality, and therapeutic efficacy [3] [11]. A fundamental understanding of the distinctions between Good Manufacturing Practice (GMP) and Good Tissue Practice (GTP) is essential for designing compliant manufacturing processes. GMP provides the comprehensive system for ensuring product quality, while GTP requirements focus specifically on preventing the introduction and transmission of communicable diseases by human cells, tissues, and cellular and tissue-based products (HCT/Ps) [12]. This application note details the specific requirements and provides protocols to facilitate compliance for patient-specific stem cell therapy development.

Regulatory Framework: CBER, GMP, and GTP

The Role of FDA CBER

CBER is responsible for regulating biological products for human use. This includes stem cell therapies, which are often evaluated as somatic cell therapy products [10]. For medical devices that are integral to the collection or manufacturing process of these biologics—such as blood collection and processing devices—CBER also maintains regulatory jurisdiction [13] [14]. This oversight ensures that the entire ecosystem surrounding a cell therapy product, from the starting material to the final product, is held to a consistent standard of quality and safety.

GMP Requirements in Detail

Current Good Manufacturing Practice (CGMP) regulations represent the minimum requirements for ensuring that drugs—including finished pharmaceuticals like stem cell therapies—are manufactured with consistent strength, purity, and quality [15]. The core CGMP regulations for finished pharmaceuticals are detailed in 21 CFR Part 211, while general GMP principles are in 21 CFR Part 210 [15] [12]. These regulations are not merely guidelines but are enforceable standards, and compliance is mandatory for product approval and marketing [15] [3].

Table: Key CGMP Regulations for Cell Therapy Products

| 21 CFR Part | Regulatory Focus | Key Requirements for Cell Therapy Manufacturing |

|---|---|---|

| Part 211 (Finished Pharmaceuticals) | Comprehensive quality standards for drug products [12]. | Organization & Personnel, Buildings & Facilities, Equipment, Control of Components & Containers, Production & Process Controls, Laboratory Controls, Records & Reports [12]. |

| Part 600 (Biological Products) | Establishment standards for biological products [12]. | Personnel, Physical Establishment, Equipment, Records, Retention Samples, Reporting of Deviations [12]. |

| Part 1271 (HCT/Ps) | Good Tissue Practice (GTP) requirements for preventing contamination [12]. | Donor Eligibility, Current GTP, Registration & Listing (Note: Part 1271 is specifically for GTP, not GMP) [12]. |

For cell therapies, GMP compliance requires a meticulous, well-documented approach from the initial cell acquisition through to the final product release. Key considerations outlined in the regulations and supporting literature include [3] [11] [12]:

- Organization and Personnel: A qualified quality control unit must be established with the responsibility and authority to approve or reject all components, drug product containers, closures, in-process materials, packaging, labeling, and the final drug product.

- Buildings and Facilities: Designed with adequate space and cleanroom classifications (e.g., ISO 7 or better) to prevent contamination or mix-ups. Air filtration, ventilation, and environmental monitoring are critical.

- Production and Process Controls: Written procedures must be established and followed, with strict control over aseptic processing, equipment calibration, and in-process testing. Yields must be calculated and deviations investigated.

- Laboratory Controls: Requirements for testing and release for distribution, stability testing, and reserve samples. This includes rigorous testing for sterility, mycoplasma, endotoxin, and cell identity, viability, and potency.

GTP vs. GMP: A Comparative Analysis

While GMP provides the overarching quality framework for the final drug product, Good Tissue Practice (GTP) requirements under 21 CFR Part 1271 focus specifically on the handling of human cells, tissues, and cellular and tissue-based products (HCT/Ps) to prevent the introduction, transmission, and spread of communicable diseases [12]. For an autologous stem cell therapy, both sets of regulations apply. GTP governs the donor screening and testing (even for autologous donors), and the handling of cells as HCT/Ps, while GMP governs the subsequent manufacturing of those cells into a finished drug product.

Table: GTP vs. GMP Requirements for Patient-Specific Stem Cell Therapies

| Aspect | Good Tissue Practice (GTP) Focus | Good Manufacturing Practice (GMP) Focus |

|---|---|---|

| Primary Objective | Prevent communicable disease transmission [12]. | Ensure safety, identity, strength, quality, and purity of the drug product [15]. |

| Scope | Donor eligibility, procurement, storage, and handling of HCT/Ps [12]. | Entire manufacturing process from receipt of raw materials to finished product release [15] [12]. |

| Donor Eligibility | Required: donor screening and testing [12]. | Not applicable to GMP as a standalone requirement; donor eligibility is a GTP function. |

| Facility Control | Focus on preventing cross-contamination between HCT/Ps [12]. | Comprehensive control of entire facility, including cleanroom standards, environmental monitoring, and pest control [12]. |

| Process Validation | Not explicitly required under GTP. | Required under GMP (21 CFR 211.100, 211.113) to ensure process reproducibility and control of microbiological contamination [12]. |

| Personnel | Training relevant to tasks performed on HCT/Ps [12]. | Established organizational structure with a dedicated quality unit; extensive GMP training [12]. |

GMP Compliance for Patient-Specific Therapies: Key Considerations

Manufacturing patient-specific stem cell therapies under GMP presents unique challenges. The following considerations, derived from current regulatory guidance and scientific literature, are critical for success [16] [11] [17]:

- Autologous vs. Allogeneic Source: Autologous therapies use the patient's own cells, which eliminates concerns of immune rejection but introduces significant logistical hurdles. These include individualized batch production, tracking, and testing, often under tight time constraints for acute conditions. Allogeneic "off-the-shelf" products offer scalability but require careful assessment of donor-specific immune responses [11].

- Donor and Cell Source: The donor's age, gender, health status, and tissue source (e.g., bone marrow, adipose tissue, umbilical cord) can significantly impact the properties and therapeutic efficacy of the final MSC product. This biological variability must be accounted for in process development and quality control [11].

- Cell Expansion and Culture Media: The expansion process (isolation method, plating density, passage number) must be standardized and validated. The use of undefined media supplements like fetal bovine serum (FBS) is discouraged due to risks of contamination and variability. GMP-compliant, xenogeneic-free alternatives, such as human platelet lysate (hPL) or chemically defined media, are essential for clinical-grade production [11].

- Product Fitness and Cryopreservation: Most "off-the-shelf" therapies are cryopreserved. The cryopreservation process and the choice of cryoprotectant (preferably xenogeneic-free and DMSO-free) can significantly impact cell viability, functionality, and in vivo persistence post-thaw. These effects must be thoroughly characterized [11].

- Process Automation and Closed Systems: Implementing automated, closed-system technologies is key to reducing manual errors, preventing contamination, enhancing process consistency, and enabling scalability. Automated systems for cell separation, washing, concentration, and genetic modification are increasingly available and vital for GMP compliance [17].

Experimental Protocols for GMP-Compliant Manufacturing

Protocol: GMP-Compliant Expansion of Mesenchymal Stromal Cells (MSCs)

This protocol outlines a standardized process for the expansion of clinical-grade MSCs, aligning with cGMP considerations highlighted in recent research [11].

I. Objective: To isolate and expand human MSCs from bone marrow aspirate under GMP-compliant conditions for use in clinical trials.

II. Materials and Reagents

- Starting Material: Bone marrow aspirate from qualified donor.

- Culture Media: Xeno-free, serum-free MSC expansion medium.

- Supplement: GMP-grade human platelet lysate (hPL).

- Dissociation Reagent: GMP-grade recombinant trypsin-like enzyme.

- Consumables: Single-use, sterile cell culture flasks/vessels, pipettes, and centrifugation tubes.

III. Methodology

- Cell Isolation and Seeding:

- Dilute bone marrow aspirate 1:1 with PBS containing 1% human serum albumin.

- Isolate mononuclear cells using density gradient centrifugation (e.g., Ficoll-Paque) or an automated, closed-system cell processing device.

- Wash cells twice with PBS/albumin and count viable cells using an automated cell counter.

- Seed cells at a density of 5x10^3 cells/cm² in culture vessels pre-filled with complete culture medium (base medium supplemented with 5% hPL).

- Cell Culture and Expansion:

- Incubate cultures at 37°C, 5% CO₂.

- Perform a complete medium exchange every 2-3 days.

- Monitor cells daily for morphology, confluence, and any signs of contamination.

- Cell Passaging:

- Once cells reach 70-80% confluence, remove culture medium and wash with PBS.

- Add dissociation reagent and incubate until cells detach.

- Neutralize the enzyme with complete medium and collect the cell suspension.

- Centrifuge, resuspend, and perform a viable cell count.

- Re-seed cells at the same initial density (5x10^3 cells/cm²) for continued expansion. Do not exceed passage 6 to maintain genomic stability.

- Cell Harvest and Cryopreservation:

- Upon achieving the target cell number, harvest cells as in step 3.

- Resuspend the final cell pellet in a GMP-compliant cryoprotectant solution (e.g., containing 5-10% DMSO and human serum albumin) at a pre-defined concentration.

- Fill controlled-rate freezing bags or vials and cryopreserve using a programmed freezer.

- Transfer to a GMP-managed liquid nitrogen storage system.

IV. Quality Control Testing

- Identity: Flow cytometry analysis for positive (CD73, CD90, CD105) and negative (CD34, CD45, HLA-DR) MSC surface markers.

- Viability: >80% viability post-thaw, assessed by trypan blue exclusion or flow-based methods.

- Potency: Assay tailored to mechanism of action (e.g., immunosuppression assay using T-cell proliferation).

- Safety: Sterility (bacteria/fungi), mycoplasma, and endotoxin testing per pharmacopoeial methods. Karyotyping at initial master cell bank and at end of production.

Protocol: Process Validation for Aseptic Manufacturing

I. Objective: To validate the aseptic manufacturing process for a patient-specific stem cell therapy, demonstrating a sterility assurance level (SAL) of 10^-3 or better.

II. Materials

- Sterile culture media and reagents.

- Environmental monitoring equipment (settling plates, air samplers, contact plates).

- Process simulation (media fill) containers identical to product containers.

- Tryptic Soy Broth (TSB) and Fluid Thioglycollate Medium (FTM).

III. Methodology

- Simulation Setup:

- Perform the media fill simulation using TSB in the actual GMP manufacturing suite.

- The simulation must mimic the entire aseptic process, including all manual manipulations, durations, and interventions, from the inoculation of the starting material (simulated with TSB) to the final container closure.

- Use the same equipment and personnel as in the actual manufacturing process.

- Execution:

- A minimum of three separate runs should be performed, each representing a worst-case scenario (e.g., maximum number of operator interventions, longest process duration).

- Incubate all media-filled containers at 20-25°C for 14 days and at 30-35°C for 7 days.

- Observe containers for microbial growth at regular intervals.

- Acceptance Criteria:

- The process is considered validated if no more than 1 out of 3000-5000 units (depending on batch size) shows contamination, which corresponds to the target SAL.

- Any contaminated unit must be investigated to identify the root cause (e.g., environmental monitoring data, personnel practices).

The Scientist's Toolkit: Essential Reagents and Materials

Table: Key Research Reagent Solutions for GMP Cell Therapy Manufacturing

| Reagent/Material | Function | GMP-Compliant Considerations |

|---|---|---|

| Xeno-Free Cell Culture Medium | Provides nutrients for cell growth and expansion. | Must be chemically defined, devoid of animal-derived components, and manufactured under a quality system. Supports batch-to-batch consistency [11]. |

| Human Platelet Lysate (hPL) | Serum substitute that provides growth factors and adhesion proteins. | Must be sourced from certified human donors, tested for pathogens, and processed to remove platelets and cellular debris. A GMP-grade alternative to FBS [11]. |

| Cell Dissociation Reagents | Enzymatically detaches adherent cells for passaging. | Recombinant, non-animal derived enzymes (e.g., trypsin replacements) are preferred. Must be sterile and supplied with a Certificate of Analysis [17]. |

| Cryopreservation Medium | Protects cells from ice-crystal damage during freeze-thaw. | Formulations should be DMSO-free or use low concentrations. All components must be pharmaceutical-grade and the final mixture sterile-filtered [11]. |

| Cell Separation Reagents | Isolates target cell populations (e.g., T-cells, MSCs) from heterogeneous mixtures. | Antibody cocktails and magnetic beads must be clinically approved, supplied in sterile, single-use vials, and used within closed-system automated instruments [17]. |

Workflow and Regulatory Pathway Visualizations

Regulatory Pathway for CBER Submission

GMP Manufacturing Workflow for Autologous Therapy

Successfully bringing a patient-specific stem cell therapy from research to clinic under the purview of FDA CBER demands a proactive and integrated understanding of GMP and GTP regulations. The regulatory framework, centered on 21 CFR Parts 211, 210, 600, and 1271, is designed to be dynamic, evolving with scientific progress to ensure rigorous safety and quality standards without stifling innovation [15] [3] [12]. By embedding GMP principles into the earliest stages of process development—through careful consideration of cell source, raw materials, process automation, and robust quality control—researchers and drug developers can build a solid foundation for clinical translation. Adherence to these detailed application notes and protocols will help in navigating this complex landscape, ultimately accelerating the delivery of safe and effective transformative therapies to patients.

The field of stem cell research and therapy has witnessed remarkable advancements over the past decade, progressing from foundational laboratory studies to approved clinical treatments for previously untreatable conditions. This rapid evolution has necessitated the development of robust international standards and harmonization efforts to ensure scientific rigor, patient safety, and ethical integrity across global research and clinical applications. The International Society for Stem Cell Research (ISSCR) serves as the preeminent global organization establishing guidelines that address the international diversity of cultural, political, legal, and ethical issues associated with stem cell research and its translation to medicine [1].

The primary societal mission of basic biomedical research and its clinical translation is to alleviate and prevent human suffering caused by illness and injury. This collective effort depends on public support and contributions from many stakeholders, including scientists, clinicians, patients, research participants, industry members, regulators, and governmental officials [1]. Global harmonization of regulatory frameworks has become increasingly crucial as cell and gene therapies demonstrate therapeutic potential, with nearly 50 therapies approved in the United States alone as of 2025 [18]. These harmonization efforts aim to streamline development processes, reduce costs, facilitate international collaborations, and ultimately hasten patient access to life-saving treatments across geographical boundaries [19].

Current International Regulatory Landscape

ISSCR Guidelines Framework

The ISSCR Guidelines for Stem Cell Research and Clinical Translation underwent a targeted update in 2025, maintaining fundamental principles while responding to scientific advances. The guidelines maintain and underscore widely shared principles in science that call for rigor, oversight, and transparency in all areas of practice [1]. The 2025 update specifically refined recommendations for stem cell-based embryo models (SCBEMs) in response to scientific and oversight developments in this rapidly evolving area [7].

Table: Key Revisions in ISSCR 2025 Guidelines Update

| Aspect Updated | Previous Approach | 2025 Revision |

|---|---|---|

| Terminology | Classification as "integrated" or "non-integrated" models | Inclusive term "SCBEMs" |

| Oversight Requirements | Varied by model type | All 3D SCBEMs require clear rationale, defined endpoint, and appropriate oversight |

| Transplantation Restrictions | Specific prohibitions | Reiterated prohibition on uterine transplantation in living hosts |

| Culture Limitations | Not explicitly addressed | Prohibits ex vivo culture to point of potential viability (ectogenesis) |

The ISSCR Standards for Human Stem Cell Use in Research, released in 2023, provide additional guidance designed to enhance reproducibility and rigor of stem cell research through minimum characterization and reporting criteria for scientists working with human stem cells [20]. These standards include a "Reporting Practices for Publishing Results with Human Pluripotent and Tissue Stem Cells" checklist to help scientists, reviewers, and journal editors assess manuscripts for inclusion of critical details relevant to stem cell work [20].

Global Regulatory Variations

Regulatory frameworks governing cell and gene therapies vary significantly across the globe, shaped by unique regional medical, ethical, safety, and economic considerations [19]. These variations affect how therapies are developed, approved, and brought to market, impacting the speed and availability of innovative treatments.

Table: Regional Regulatory Approaches for Advanced Therapies

| Region | Regulatory Body | Key Initiatives/Pathways | Notable Characteristics |

|---|---|---|---|

| United States | Food and Drug Administration (FDA) | Regenerative Medicine Advanced Therapy (RMAT), Fast Track | Progressive policies under 21st Century Cures Act |

| European Union | European Medicines Agency (EMA) | PRIME (PRIority MEdicines) | Enhanced support for promising medicines targeting unmet needs |

| United Kingdom | Medicines and Healthcare products Regulatory Agency (MHRA) | Innovative Licensing and Access Pathway (ILAP) | Accelerated time to market post-Brexit |

| Japan | Pharmaceuticals and Medical Devices Agency (PMDA) | Accelerated approval system | Leader in regenerative therapy approval in Asia |

| Canada | Health Canada | Advanced Therapeutic Products Pathway | Flexible regulatory oversight adapting to novel therapies |

| Australia | Therapeutic Goods Administration (TGA) | Priority Review Pathway, Provisional Approval | Expedited approval for serious conditions |

| China | National Medical Products Administration (NMPA) | Accelerated approval pathways | Recent reforms for transparent review process |

The lack of regulatory harmonization poses multifaceted challenges for global pharmaceutical companies, including duplicative clinical trials, increased development costs, and elongated timelines to market entry [19]. This fragmentation is particularly problematic for cell and gene therapies, which often target rare diseases with small patient populations, making multiple separate trials to meet different regional standards both inefficient and ethically questionable [19].

GMP Compliance in Patient-Specific Stem Cell Therapies

Fundamental GMP Principles

Good Manufacturing Practice (GMP) compliance represents a critical component in the translation of stem cell research into clinically applicable therapies. GMP standards ensure that stem cell-based products are consistently produced and controlled according to quality standards appropriate for their intended use. For patient-specific therapies, this involves implementing rigorous quality control systems throughout the entire manufacturing process, from somatic cell acquisition to final therapeutic product administration.

The investigational medicinal product (IMP) manufacturing process for hematopoietic stem cell gene therapy typically involves harvesting hematopoietic stem cells expressing CD34 from apheresis of mobilized peripheral blood, isolation of CD34+ cells, pre-stimulation, ex vivo transduction with lentiviral vectors, and various quality control checks before administration to the patient [21]. The complexity of these processes demands comprehensive documentation, environmental monitoring, and quality assurance systems to prevent contamination, cross-contamination, and errors.

GMP Manufacturing Protocol: Hematopoietic Stem Cell Gene Therapy

The following detailed protocol outlines a GMP-compliant manufacturing process for hematopoietic stem cell gene therapy (HSCGT) based on established methodologies [21].

Materials and Equipment

Table: Essential Reagents and Materials for GMP HSCGT Manufacturing

| Category | Specific Reagents/Materials | Function/Purpose |

|---|---|---|

| Cell Source | Patient peripheral blood CD34+ cells | Starting material for genetic modification |

| Mobilization Agents | G-CSF, Plerixafor | Mobilize stem cells to peripheral blood |

| Cell Separation | CliniMACSplus instrument with magnetic beads | Isolation of CD34+ cells |

| Culture Media | Serum-free X-VIVO-15 | Base medium for cell culture |

| Media Supplements | Human albumin serum (HAS) | Protein supplement, cryoprotectant |

| Cytokines/Growth Factors | Flt3-L, SCF, TPO, IL-3 | Promote cell survival, proliferation, and maintenance of stemness |

| Transduction Enhancers | LentiBOOST, Protamine sulfate | Improve transduction efficiency |

| Vector | GMP-grade lentiviral vector | Gene delivery vehicle |

| Quality Assessment | Flow cytometry, CFU assays, Vector copy number (VCN) analysis | Assess cell phenotype, functionality, and transduction efficiency |

Step-by-Step Manufacturing Process

Patient Cell Mobilization and Collection

- Administer granulocyte-colony stimulating factor (G-CSF) and plerixafor to mobilize hematopoietic stem cells from bone marrow to peripheral blood

- Perform leukapheresis to collect mobilized cells under aseptic conditions

- Transport collected cells to manufacturing facility in temperature-controlled shipping container

CD34+ Cell Isolation

- Process apheresis product using CliniMACSplus instrument with magnetic bead separation for CD34+ cell selection

- Determine cell count, viability, and purity via flow cytometry analysis

- Cryopreserve cells if not proceeding immediately to transduction

Pre-stimulation and Culture

- Thaw and wash cryopreserved CD34+ cells if applicable

- Resuspend cells in pre-stimulation media: X-VIVO-15 supplemented with 1% HAS, Flt3-L (100ng/mL), SCF (100ng/mL), TPO (100ng/mL), and IL-3 (10ng/mL)

- Incubate cells at 37°C, 5% CO₂ for 24-48 hours

Lentiviral Transduction

- Calculate required lentiviral vector quantity based on cell count and target multiplicity of infection (MOI)

- Prepare transduction media: X-VIVO-15 with 1% HAS, cytokines, and transduction enhancers (LentiBOOST at 1:100 dilution and protamine sulfate at 4μg/mL)

- Combine cells with lentiviral vector in appropriate culture vessel (bag or flask)

- Perform two sequential transductions at 24-hour intervals with incubation at 37°C, 5% CO₂

Post-transduction Culture and Harvest

- After final transduction, wash cells to remove excess vector and replenish with fresh culture media

- Continue culture for 24-48 hours to allow transgene expression

- Harvest cells, perform final formulation in cryopreservation media

- Fill final product into appropriate infusion bags

Cryopreservation and Storage

- Controlled-rate freezing to -80°C followed by transfer to vapor phase liquid nitrogen for long-term storage

- Maintain chain of identity and chain of custody throughout process

GMP Manufacturing Workflow for Patient-Specific Stem Cell Therapies

Critical Quality Control Assessments

Implementing robust quality control measures throughout the manufacturing process is essential for ensuring final product safety, purity, and potency. The following parameters should be monitored:

- Cell Viability and Count: Assess via trypan blue exclusion or automated cell counters at multiple process stages

- Cell Phenotype: Confirm CD34+ purity and absence of contaminants via flow cytometry

- Transduction Efficiency: Evaluate vector copy number (VCN) per cell using digital PCR

- Biological Function: Perform colony-forming unit (CFU) assays to assess differentiation potential

- Sterility: Test for bacterial/fungal contamination (BacT/ALERT), mycoplasma, and endotoxin

- Potency: Measure functional enzyme activity or transgene expression

Recent Advances and Clinical Applications

Approved Stem Cell Therapies and Clinical Progress

The stem cell therapy landscape has matured significantly between 2023-2025, with several therapies receiving regulatory approval and many advancing through clinical trials [9]. As of December 2024, a major review identified 115 global clinical trials involving 83 distinct pluripotent stem cell (PSC)-derived products targeting indications in ophthalmology, neurology, and oncology, with over 1,200 patients dosed and no significant safety concerns reported [9].

Table: Recently Approved Stem Cell-Based Therapies (2023-2025)

| Therapy Name | Approval Date | Cell Type | Indication | Key Clinical Outcomes |

|---|---|---|---|---|

| Omisirge | April 17, 2023 | Cord blood-derived hematopoietic progenitor cells | Hematologic malignancies undergoing cord blood transplantation | Accelerates neutrophil recovery, reduces infection risk |

| Lyfgenia | December 8, 2023 | Autologous cell-based gene therapy | Sickle cell disease with history of vaso-occlusive events | 88% achieved complete resolution of vaso-occlusive events (6-18 months) |

| Ryoncil | December 18, 2024 | Allogeneic bone marrow-derived MSCs | Pediatric steroid-refractory acute graft versus host disease | First MSC therapy approval for SR-aGVHD |

| Fertilo | FDA IND clearance February 2025 | iPSC-derived ovarian support cells | Support ex vivo oocyte maturation | Phase III trial, first live birth reported |

Emerging Technologies and Approaches

Several emerging technologies are shaping the future of stem cell therapy manufacturing and clinical application:

iPSC-Derived MSCs (iMSCs): Offering enhanced consistency and scalability compared to primary MSCs, iMSCs are gaining momentum in regenerative medicine trials targeting conditions such as osteoarthritis and tissue repair [9].

Off-the-Shelf Allogeneic Products: Development of universal donor cell lines aims to overcome limitations of patient-specific therapies, including production time and cost [18].

Point-of-Care Manufacturing: Automated, closed-system platforms enable decentralized manufacturing within treatment institutions, reducing logistical burdens and potentially improving access [18].

Enhanced Gene Editing: CRISPR/Cas9 and other precision gene editing technologies allow for more targeted genetic modifications in stem cell therapies.

Global Harmonization Initiatives

Current Harmonization Efforts

Global harmonization of cell and gene therapy regulations has gained significant momentum, with multiple initiatives aimed at aligning regulatory requirements across regions. The International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) has endorsed a proposal to develop guidance on manufacturing changes for cell and gene therapies, known as Advanced Therapy Medicinal Products (ATMPs) [22]. This initiative, led by the Biotechnology Innovation Organization (BIO), addresses the critical issue of comparability when manufacturing processes are modified.

The comparability challenge is particularly complex for ATMPs, which range from relatively simple mRNA-based products to highly complex cell-based therapies like CAR-T cells and stem-cell derived products [22]. The proposed guidelines aim to establish global standards for demonstrating comparability following manufacturing changes, reducing redundant efforts and regulatory delays across different countries.

Benefits of Harmonized Regulations

The harmonization of regulatory frameworks across regions offers substantial benefits:

Accelerated Patient Access: Aligned approval standards and procedures reduce redundancy and minimize delays, facilitating smoother transition of therapies from clinical trials to market [19].

Enhanced International Collaboration: Unified standards enable multi-center trials with consistent requirements, promoting global sharing of data and resources [19].

Reduced Development Costs: Streamlined operations and leveraged efficiencies lower financial barriers, particularly important in resource-intensive regenerative medicine [19].

Predictable Market Conditions: Harmonized regulations reduce regulatory risk, encouraging investment in innovative therapies [19].

Global Harmonization Framework for Advanced Therapies

Implementation Challenges and Future Directions

Addressing Implementation Barriers

Despite progress in standardization and harmonization, significant challenges remain in implementing these frameworks globally:

Financial Barriers: The high costs of cell and gene therapies (ranging from ~$275,000 to >$4 million in the U.S.) present substantial challenges to broad implementation and equitable access [18].

Infrastructure Limitations: Complex manufacturing and administration requirements limit use to large academic centers, particularly impacting lower- to middle-income countries (LMICs) [18].

Regulatory Discrepancies: Differing requirements across regions necessitate duplicate trials and create logistical challenges for global development programs [19].

Manufacturing Complexity: The personalized nature of many stem cell therapies creates supply chain challenges and limits scalability [18].

Strategies for Enhanced Global Implementation

Several strategies are emerging to address these challenges and promote wider adoption of stem cell therapies:

Alternative Manufacturing Models: Point-of-care manufacturing utilizing automated, closed platforms can increase production efficiency and reduce error while maintaining quality [18].

Academic-Industry Partnerships: Collaboration between academic researchers, pharmaceutical companies, and non-profit entities can help develop sustainable models for therapy development and distribution [18].

Innovative Payment Structures: Alternative financing models, including outcome-based agreements and installment payments, can address the challenge of high upfront costs [18].

Capacity Building: Programs to establish manufacturing infrastructure and train specialized personnel in underserved regions can promote more equitable global access [1].

The field continues to evolve rapidly, with the ISSCR maintaining an agile approach to guideline updates through targeted revisions in response to scientific advances [7]. This responsive framework ensures that international standards remain relevant and effective in promoting ethical, practical, and sustainable approaches to stem cell research and clinical translation.

Risk-Based Approaches for Early-Phase Clinical Trials and Commercial Manufacturing

Within the development of patient-specific stem cell therapies, the application of a risk-based approach to Good Manufacturing Practice (GMP) compliance is fundamental to navigating the journey from early-phase clinical trials to commercial manufacturing. This philosophy, endorsed by regulatory agencies like the FDA, allows developers to focus resources on areas most critical to patient safety and product quality [23] [24]. For advanced therapies, which are often characterized by high complexity and a lack of terminal sterilization, integrating risk management from the outset is not just beneficial—it is essential for ensuring both regulatory compliance and the delivery of safe, effective treatments [25] [23].

This document outlines practical, phase-appropriate strategies for implementing risk-based GMP systems, providing structured protocols and visual guides to support researchers, scientists, and drug development professionals in this innovative field.

Phase-Appropriate Application of Risk-Based GMP

The core principle of a risk-based approach is that the level of control and documentation should be commensurate with the stage of development and the potential risks to product quality and patient safety [26] [24]. The following table summarizes the key differences in applying GMP principles during early-phase development versus commercial manufacturing for patient-specific stem cell therapies.

Table: Risk-Based GMP Considerations Across Development Phases

| Aspect | Early-Phase Clinical Trials (Phase I-IIa) | Commercial Manufacturing (Phase III & Beyond) |

|---|---|---|

| Primary Focus | Patient safety, proof-of-concept, and process learning [26] [23]. | Consistent product quality, efficacy, and commercial viability. |

| Stability Studies | "Fit-for-purpose" data to support storage and clinical use duration; one representative batch may be sufficient [26]. | Full ICH-compliant stability programs to define shelf life; multiple batches required [26]. |

| Process Validation | Emphasis on controlling Critical Process Parameters (CPPs) and monitoring Critical Quality Attributes (CQAs) for early process consistency [23]. | Full, formal process validation required to demonstrate the process consistently produces product meeting its pre-defined specifications. |

| Specifications | Preliminary, based on limited data and focused on safety attributes (e.g., sterility, viability, identity) [26]. | Comprehensive and justified by substantial data from multiple GMP batches. |

| Documentation | Phase-appropriate, with a focus on traceability and data integrity for critical steps [27]. | Extensive and rigorous documentation system, fully aligned with updated Chapter 4 EU GMP guidelines and data integrity principles (ALCOA++) [27]. |

| Facility & Equipment | Flexible, adaptable systems that can handle process changes; closed and automated systems to minimize contamination risk [23] [17]. | Fixed, validated, and scalable processes with qualified equipment in a dedicated, controlled environment. |

A proactive risk management framework is the cornerstone of operations in early-phase development [23]. From procuring raw materials to defining product release specifications, each unit operation is strategically evaluated throughout the product development lifecycle. This ensures that resources are directed toward high-risk areas, such as sterility, cell viability, and dose determination, while allowing for greater flexibility in lower-risk areas to foster innovation and efficiency [23] [24].

Experimental Protocols for a Risk-Based Approach

Protocol: Risk Assessment for Raw Materials in Cell Therapy Manufacturing

1. Objective: To establish a systematic methodology for identifying, assessing, and controlling risks associated with raw and ancillary materials used in the production of patient-specific stem cell therapies.

2. Materials:

- List of all raw materials, reagents, and supplements (e.g., growth factors, cytokines, culture media).

- Supplier qualification data.

- Risk Assessment Tool (e.g., Failure Mode and Effects Analysis - FMEA template).

3. Methodology: a. Risk Identification: * Form a cross-functional team (Quality, Process Development, Manufacturing). * Brainstorm potential failure modes for each material (e.g., supplier variability, endotoxin contamination, presence of animal-derived components, stability issues).

4. Documentation: The risk assessment, including the rationale for all scores and defined control strategies, must be documented and approved within the Quality System.

Protocol: Phase-Appropriate Stability Study for an Autologous Stem Cell Product

1. Objective: To generate "fit-for-purpose" stability data for an investigational autologous stem cell therapy to support the proposed storage conditions and use period for an early-phase (Phase I/II) clinical trial.

2. Materials:

- Representative batch(es) of the final drug product in its intended container closure system.

- Qualified stability chambers set to specified storage conditions (e.g., vapor phase of liquid nitrogen, controlled-rate freezer).

- Fit-for-purpose and validated analytical methods for testing.

3. Methodology: a. Study Design: * Utilize a bracketing or matrixing approach if justified [26]. * Store samples under long-term storage conditions and potential accelerated or stress conditions to understand degradation pathways. * Plan testing time points to cover the clinical use period (e.g., time-zero, midpoint, and end-of-use period).

4. Data Analysis & Reporting: * The data should support the proposed shelf life and storage conditions described in the Investigational New Drug (IND) application [26]. * A stability protocol must be written, and all data must be traceable and reliable [26].

Workflow Diagram: Risk-Based Manufacturing of Patient-Specific Therapies

The following diagram illustrates the integrated, risk-managed workflow for manufacturing a patient-specific stem cell therapy, from cell collection to patient infusion.

Autologous Therapy Manufacturing Workflow

The Scientist's Toolkit: Essential Research Reagent Solutions

Successful development and manufacturing of cell-based therapies depend on using well-characterized materials. The following table details key reagent solutions and their critical functions in the process.

Table: Essential Reagents for Stem Cell Therapy Manufacturing

| Reagent / Material | Function | GMP Considerations |

|---|---|---|

| Cell Culture Media | Provides essential nutrients for cell growth, viability, and expansion. | Use of xeno-free, chemically defined GMP-grade formulations to ensure consistency and reduce risk of contamination [17]. |

| Growth Factors & Cytokines | Directs stem cell differentiation, expansion, and maintains potency. | High purity and well-documented sourcing. Requires stringent testing for identity, potency, and purity [25]. |

| Cell Separation Reagents | Isulates target cell populations from a heterogenous starting material (e.g., leukapheresis product). | Use in closed, automated systems (e.g., counterflow centrifugation, magnetic separation) to ensure sterility and reproducibility [17]. |

| Genetic Modification Tools | (If applicable) For introducing new genetic material (e.g., CRISPR/Cas9 components, viral vectors). | Comprehensive characterization and testing for safety (e.g., absence of replication-competent viruses). Documentation of lineage and manufacturing process is critical [25]. |

| Cryopreservation Media | Allows for long-term storage of final drug product and intermediate cell banks. | Formulated with GMP-grade cryoprotectants (e.g., DMSO). Requires validation of the freeze-thaw process to ensure post-thaw viability and function [25]. |

For researchers and drug development professionals working on patient-specific stem cell therapies, establishing a robust system for documentation and traceability is not merely a regulatory hurdle; it is the foundational element that ensures product quality, patient safety, and the scientific integrity of the entire development process. Advanced Therapy Medicinal Products (ATMPs), which include cell and gene therapies, fall under pharmaceutical law, making compliance with Good Manufacturing Practice (GMP) mandatory [3] [28]. The biological nature of these living therapies introduces unique challenges—each starting material and reagent is effectively part of the final product [28]. Consequently, a seamless, well-documented quality system that bridges research and clinical translation is essential for transforming a promising laboratory discovery into a regulated, clinically viable therapy.

Foundational Principles: GMP and the Regulatory Landscape

What is GMP and Why is it Non-Negotiable?

Good Manufacturing Practice (GMP) is a quality assurance system that ensures products are consistently produced and controlled according to state-of-the-art quality standards appropriate to their intended use [3]. In the context of ATMPs, GMP encompasses all aspects of the manufacturing process, including:

- Premises and equipment

- Staff training

- Operational processes

- Packaging and storage conditions

- Overarching quality assurance and comprehensive documentation systems [3]

The primary mission is to protect patients by ensuring that every product batch is safe, pure, potent, and reliable. The U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) require that ATMP manufacture adheres to GMP guidelines, and full marketing approval is contingent upon the successful submission of a Biologics License Application (BLA) or equivalent, which is heavily reliant on exhaustive documentation [9] [28].

The Documentation Hierarchy in a GMP Environment

A robust GMP documentation system is layered, with each level serving a distinct purpose. The following diagram illustrates the logical relationships and flow within a GMP documentation system.

Diagram 1: The hierarchical structure of GMP documentation, from overarching regulations to specific records.

This hierarchy ensures that every action is traceable back to an approved procedure and, ultimately, to regulatory requirements. Key documents include:

- Policy Manuals: Top-level documents describing overall laboratory management and organization [29].

- Standard Operating Procedures (SOPs): Provide detailed, specific requirements for laboratory activities [29].

- Test Methods and Specifications: Step-wise directions for test procedures and their pass/fail criteria [29].

- Records and Raw Data: Laboratory notebooks, testing sheets, and analytical printouts that provide evidence of what was actually done [29].

Application Note: A Practical Framework for GMP-Compliant iPSC Banking

Generating a clinical-grade induced pluripotent stem cell (iPSC) bank is a critical first step in manufacturing patient-specific therapies. The following section outlines a standardized protocol for establishing a GMP-compliant master cell bank, complete with essential quality control metrics.

Experimental Protocol: GMP-Compliant iPSC Line Generation and Banking

Objective: To generate, characterize, and bank a clonal, GMP-compliant iPSC master cell line from a qualified somatic cell source for use in manufacturing patient-specific therapies.

Starting Material: Somatic cells (e.g., from cord blood CD34+ cells or patient biopsy) from a qualified and consented donor [30].

Key Reagent Solutions: Table 1: Essential GMP-Compliant Reagents for iPSC Generation and Culture

| Reagent / Material | Function | GMP-Compliant Example / Consideration |

|---|---|---|

| Reprogramming Vectors | Introduction of reprogramming factors. | Use of non-integrating, episomal vectors to avoid genomic modification [30]. |

| GMP-compliant Culture Medium | Supports iPSC growth and maintenance. | Defined, xeno-free media (e.g., StemMACS iPS-Brew XF) [30]. |

| Cell Culture Substrate | Surface for cell attachment and growth. | Defined substrates like iMatrix-511 [30]. |

| Passaging Reagent | Detaches cells for sub-culturing. | Enzymatic, animal-origin-free reagents like Accutase [30]. |

| Rho-associated kinase (ROCK) inhibitor | Improves cell survival after passaging. | Use of Y-27632 at 10 µM [30]. |

Methodology:

- Reprogramming: Transfect the qualified somatic cell source with the non-integrating reprogramming vector system. Use a validated electroporation device and protocol [30].

- Clonal Isolation and Expansion: Culture transfected cells under GMP-compliant conditions. Manually pick emerging iPSC colonies based on characteristic morphology and expand them clonally. Use a ROCK inhibitor (e.g., 10 µM Y-27632) during passaging to enhance survival [30].

- Master Cell Bank (MCB) Creation: Once a clonal line is expanded, cryopreserve a large number of vials at an early passage as the MCB. Use controlled-rate freezing and validated cryostorage conditions. The entire process must be documented in a detailed batch record [30].

Quality Control and Release Specifications for iPSC Master Cell Banks

A comprehensive set of quality control (QC) tests must be performed on the MCB prior to its release for further differentiation. The results must meet pre-defined specifications, documented in a Certificate of Analysis (CoA).

Table 2: Example QC Release Specifications for a GMP-Compliant iPSC Master Cell Bank

| QC Test Category | Specific Test / Assay | Release Specification | Rationale |

|---|---|---|---|

| Identity | Short Tandem Repeat (STR) Profiling | Match with donor somatic cells | Confirms lineage and absence of cross-contamination [30]. |

| Potency / Pluripotency | Flow Cytometry (SSEA-4, TRA-1-60) | >90% positive for pluripotency markers | Verifies functional pluripotent state [30]. |

| Viability & Sterility | Viability (Trypan Blue exclusion) | >90% post-thaw viability | Ensures product fitness. |

| Mycoplasma Testing (qPCR) | Negative | Prevents contamination [30]. | |

| Safety | Sterility (Bacterial/Fungal culture) | No growth observed | Ensures aseptic processing [3]. |

| In Vitro Tumorigenicity (Soft Agar Assay) | No colony formation | Assesses oncogenic potential [30]. | |

| Purity / Genetic Integrity | Karyotype (G-banding) | Normal (46, XX or XY) | Confirms genomic stability at a macroscopic level [30]. |

| Whole-Genome Sequencing (WGS) | Low overall mutation load, absence of pathogenic variants in oncogenes/tumor suppressors | Identifies sub-microscopic genetic variants; neonatal cord blood-derived lines have shown a low mutation load [30]. |

Traceability in Practice: From Ancillary Materials to Final Product

Traceability is the golden thread that runs through the entire product lifecycle. It requires that the origin and history of every component and process step can be precisely determined.

Managing Ancillary Materials (AMs)

Ancillary materials (AMs) are critical reagents used in the manufacturing process, such as cell culture media, cytokines, and enzymes. Since they contact the cells, their quality is integral to the final ATMP [28]. A secure supply chain with comprehensive documentation is vital.

Required Documentation for GMP-Compliant AMs:

- Certificate of Analysis (CoA): Confirms the product meets defined quality and performance standards [28].

- Certificate of Origin (CoO): Details the source of all raw materials [28].

- TSE Certificate: Certifies that animal-derived products minimize the risk of Transmissible Spongiform Encephalopathy [28].

- Drug Master File (DMF): A confidential, detailed file submitted to the FDA by the supplier. An Investigational New Drug (IND) application sponsor can reference a DMF via a Letter of Authorization (LoA) from the supplier, streamlining the regulatory review [9] [28].

Recommendation: Transition from research-grade to GMP-compliant AMs early in the R&D/pre-clinical phases. Changing AMs later necessitates costly and time-consuming comparative studies to demonstrate product consistency [28].

The Product Journey and Chain of Identity

For patient-specific therapies, maintaining a secure "chain of identity" from the patient donor to the final infused product is paramount. The workflow below visualizes this traceability and documentation flow.

Diagram 2: The product journey and critical traceability points for a patient-specific stem cell therapy.

Building a robust quality system founded on comprehensive documentation and traceability is a strategic imperative for successfully translating patient-specific stem cell therapies from the research bench to the clinic. By integrating GMP principles early, securing a well-documented supply chain for ancillary materials, and implementing a hierarchical documentation system, developers can navigate the complex regulatory landscape with confidence. This disciplined approach not only safeguards patient safety and ensures regulatory compliance but also generates the high-quality, reproducible data essential for proving the efficacy and commercial viability of these transformative advanced therapies.

Practical Implementation of GMP Systems and Manufacturing Processes

For manufacturers of patient-specific stem cell therapies, the cleanroom facility is a critical cornerstone of product quality, patient safety, and regulatory compliance. Adherence to Good Manufacturing Practice (GMP) is a legal requirement for Advanced Therapy Medicinal Products (ATMPs), which include stem cell-based therapies [3] [25]. The cleanroom provides the controlled environment necessary to prevent microbiological contamination, cross-contamination between patient batches, and to ensure the consistent production of a viable, living product that cannot be terminally sterilized [25].

Cleanrooms are classified according to the International Organization for Standardization (ISO) 14644-1 standard, which defines the maximum permissible concentration of airborne particles per cubic meter of air [31] [32]. The classification system ranges from ISO 1 (cleanest) to ISO 9 (least clean) [33]. This document will focus on the classifications most relevant to stem cell therapy production, typically spanning ISO 5 to ISO 8, and outline the integrated environmental controls and material flow required to maintain their aseptic conditions.

Cleanroom Classification and Particle Limits

The following table summarizes the key particle count requirements for ISO classes 5 through 8, which are the primary classes involved in the manufacturing of stem cell therapies. Particle counts are cumulative [34].

Table 1: ISO 14644-1 Cleanroom Classification Standards and Particle Concentration Limits (maximum particles per m³) [33] [31] [32]

| ISO Class | FED STD 209E Equivalent | ≥ 0.5 µm | ≥ 1 µm | ≥ 5 µm |

|---|---|---|---|---|

| ISO 5 | Class 100 | 3,520 | 832 | 29 |

| ISO 6 | Class 1,000 | 35,200 | 8,320 | 293 |

| ISO 7 | Class 10,000 | 352,000 | 83,200 | 2,930 |

| ISO 8 | Class 100,000 | 3,520,000 | 832,000 | 29,300 |

Different stages of the stem cell manufacturing process require different levels of environmental control. For example, open manipulations critical to product quality, such as the final formulation of the cell therapy product, must be performed in an ISO 5 environment, often provided by a laminar flow biosafety cabinet located within an ISO 7 or ISO 8 cleanroom [25] [31]. The surrounding room functions as a buffer zone, maintaining a higher air pressure to protect the critical zone from contamination ingress.

Table 2: GMP Grade Equivalents and Typical Applications in Stem Cell Therapy

| GMP Grade (EU) | Equivalent ISO Classification | Typical Applications in Stem Cell Therapy |

|---|---|---|

| Grade A | ISO 5 (in operation) | Critical processing zones (e.g., biosafety cabinets for cell manipulation, filling) |

| Grade B | ISO 7 (in operation) | Background environment for Grade A zones (e.g., aseptic preparation and filling rooms) |

| Grade C | ISO 7 / ISO 8 (in operation) | Preparation of less critical solutions, cleanroom gowning areas |

| Grade D | ISO 8 (at rest) | Handling of cleaned components, warehousing for sterilized materials |

Environmental Control Systems

HEPA Filtration and Airflow Principles

High-Efficiency Particulate Air (HEPA) filtration is the definitive technology for achieving the required air cleanliness. A true HEPA filter must capture at least 99.97% of particles 0.3 micrometers in diameter, the Most Penetrating Particle Size (MPPS) [35] [32]. Some facilities may employ Ultra-Low Penetration Air (ULPA) filters, which capture 99.999% of particles down to 0.12 microns, for stricter control [32].

The effectiveness of HEPA filtration is realized through two primary airflow strategies:

- Laminar (Unidirectional) Airflow: Air moves in a single direction at a uniform velocity (typically 0.45 m/s ±20%), creating parallel streamlines that sweep particles away from the critical processing zone. This is essential for ISO 5 (Grade A) environments [32].

- Turbulent (Non-unidirectional) Airflow: Clean, HEPA-filtered air is introduced in a way that creates mixing and dilution to control contamination. This is common in ISO 7 and ISO 8 (Grade B/C) background rooms and requires a higher number of air changes per hour to achieve cleanliness [32].

Key Design and Operational Parameters

Table 3: Cleanroom Design Requirements by ISO Classification [36] [31] [34]

| Parameter | ISO 5 / Grade A | ISO 7 / Grade B | ISO 8 / Grade C/D |

|---|---|---|---|

| Air Changes Per Hour (ACH) | 240 - 480 (approx.) | 60 - 90 (approx.) | 10 - 25 (approx.) |

| Ceiling HEPA Filter Coverage | 90 - 100% | 7 - 15% | 4 - 5% |

| Typical Airflow Pattern | Laminar | Turbulent | Turbulent |

| Typical Filtration | HEPA or ULPA | HEPA | HEPA |

Additional critical environmental parameters that must be continuously monitored and controlled include:

- Pressure Differentials: Cleanrooms maintain a cascading pressure gradient, with the cleanest rooms (e.g., ISO 5) at the highest positive pressure relative to adjacent less-clean areas. This prevents inflow of contaminated air. A differential of 1 to 20 mmHg pressure is typical [33].

- Temperature and Humidity: Tight control is required to prevent particle generation and microorganism proliferation, and to ensure staff comfort. The HVAC system must maintain these within specified limits (e.g., 20-24°C, 45-60% RH) [33] [25].

- Recovery: The cleanroom must rapidly return to its specified classification after a contamination event, such as door opening or personnel activity [33].

Material Flow and Personnel Movement

In GMP facilities, the flow of materials and personnel is designed to be logical and unidirectional to prevent cross-contamination, which is a significant risk when manufacturing patient-specific therapies [25].

Material Flow Protocol

- Introduction: All raw materials, reagents, and equipment must enter through a designated receiving and quarantine area.

- Decontamination: Materials are transferred to a staging area for decontamination. Outer packaging is removed and wiped down with a suitable disinfectant.

- Transfer into Cleanroom: Decontaminated materials are passed into the cleanroom through a double-sided pass-through hatch or airlock. Materials should never be introduced directly into a higher-grade cleanroom from an uncontrolled corridor.

- Internal Movement: Within the cleanroom, materials should move from areas of lower cleanliness (e.g., ISO 8) to higher cleanliness (e.g., ISO 7, then ISO 5).

- Waste Exit: All waste materials must be sealed in approved, non-shedding bags and removed via a dedicated exit path or pass-through to prevent cross-contamination with incoming materials.

Personnel Gowning and Entry Protocol

Personnel are a primary source of contamination. A strict, sequential gowning procedure is mandatory.

Validation and Monitoring Protocols

Cleanroom validation is a multiphase process to ensure the facility is designed, installed, and operates according to its specified ISO classification and GMP requirements [33].

Validation Phases

- Design Qualification (DQ): Documented verification that the proposed design is suitable for the intended purpose.

- Installation Qualification (IQ): Documented verification that the facility is built and installed according to the approved design and specifications. Testing is performed "as-built" (empty and without personnel).

- Operational Qualification (OQ): Documented verification that the facility operates as intended throughout all anticipated operating ranges. Testing is performed "at-rest" (with equipment installed but without personnel activity).

- Performance Qualification (PQ): Documented verification that the facility consistently performs as intended under routine production conditions. Testing is performed "in-operation" (with equipment and personnel present) [33].

Key Test Methodologies

Table 4: Cleanroom Validation Tests and Methodologies

| Test Parameter | Test Method | Acceptance Criteria | Frequency |

|---|---|---|---|

| Airborne Particle Count | Use of a discrete particle counter to measure concentration of particles at specified sizes. | Meets maximum limits for target ISO class per ISO 14644-1 [33]. | Every 6-12 months, continuous monitoring for Grade A. |

| HEPA Filter Integrity Leak Test | Introduction of a polydisperse aerosol (e.g., PAO, DOP) upstream of the filter and scanning the downstream face and seals with a probe. Leakage must be ≤ 0.01% [33] [32]. | Meets ISO 14644-3 standards. | Every 24 months. |

| Airflow Velocity & Volume | Use of an anemometer to measure velocity at HEPA filter face. Volume is calculated (T = A x V). Air changes per hour (ACH) are derived. | Velocity and ACH meet design specifications for target ISO class (e.g., 20 ACH for ISO 8) [36] [33]. | Every 12 months. |

| Airflow Visualization / Smoke Pattern Test | A smoke generator is used to release a visible stream of smoke near filters and critical zones to visualize airflow direction and uniformity. | Smoke must show unidirectional flow in laminar zones and not reverse or stagnate in critical areas [33]. | Every 12-24 months. |

| Pressure Differential | Use of a calibrated magnehelic gauge or electronic pressure transducer to measure the pressure difference between adjacent rooms. | Maintains specified cascade (e.g., ≥ 10-15 Pa between successive grades) [33]. | Continuously monitored. |

| Recovery Test | Introduction of an aerosol to artificially elevate particle count, followed by timing how long it takes for the room to recover to its specified class limit. | Time to recover is within specified limits (e.g., minutes from ISO 7 to ISO 5) [33]. | After initial qualification and post-modification. |

| Viable (Microbial) Monitoring | Settling plates (passive air sampling), active air samplers, and surface contact plates (e.g., swabs) are used to collect samples, which are then incubated to quantify microbial growth. | Action levels based on EU GMP Annex 1 or internal standards. | Daily/weekly for plates, continuous for active air samplers in Grade A. |

The Scientist's Toolkit: Essential Reagents and Materials

Table 5: Key Reagent Solutions and Materials for Cleanroom Environmental Monitoring

| Item | Function / Application | Key Consideration for GMP |

|---|---|---|

| Nutrient Agar Contact Plates | Used for surface monitoring of viable microorganisms on equipment and personnel gloves. | Growth medium must be validated for its intended use. Incubation time and temperature are specified in SOPs. |

| Tryptic Soy Agar (TSA) Settling Plates | Plates exposed to air to passively monitor airborne microbial contamination (settling by gravity). | Exposure time is standardized (e.g., 4 hours). Plates are incubated aerobically. |

| Liquid Growth Media for Air Samplers | Used in active air samplers that draw a known volume of air to quantitatively assess microbial load. | Media choice and sampling volume are validated. |

| Aerosol Challenge Agent (e.g., PAO, DOP) | A polydisperse aerosol of Polyalphaolefin (PAO) or Diocyl Phthalate (DOP) used to challenge HEPA filters during integrity testing. | The material must generate particles in the MPPS range (0.1 - 0.3 µm). Material safety data must be reviewed [32]. |

| Isopropyl Alcohol (IPA) Solutions | A common cleanroom disinfectant for wiping down surfaces and equipment. | Used at a specified concentration (e.g., 70%) and prepared with sterile water for injection (WFI). |

| Sterile, Non-Shedding Wipes | Used in conjunction with disinfectants for cleaning surfaces. Must not shed particles or fibers. | Material compatibility with disinfectants must be assessed. |

| Particle Counter Calibration Standard | A suspension of particles of known, uniform size used to calibrate airborne particle counters. | Traceable to a national standard. Calibration is performed at defined intervals per quality system. |

For the successful and compliant manufacture of patient-specific stem cell therapies, a robust facility design is non-negotiable. This requires a holistic, risk-based approach that integrates the correct cleanroom classification, precise environmental controls (HEPA filtration, pressure, temperature, humidity), and rigorously enforced, unidirectional flows for materials and personnel. Continuous validation and monitoring, as dictated by ISO standards and GMP regulations, provide the documented evidence necessary to ensure the living cellular product is manufactured in a consistently controlled and safe environment, thereby protecting the patient and ensuring product efficacy.

The manufacturing of patient-specific stem cell therapies represents a frontier in personalized medicine, yet its complexity poses significant challenges for Good Manufacturing Practice (GMP) compliance. The individual nature of autologous therapies necessitates a manufacturing paradigm where each patient batch is a unique product, requiring meticulous control to ensure safety, identity, and purity [37]. Traditional open manual processes are particularly susceptible to two critical vulnerabilities: the risk of microbial contamination and the inherent variability introduced by human operators. These challenges can compromise product quality, lead to batch failures, and ultimately delay life-saving treatments for patients [38] [39].