GMP Manufacturing for Clinical-Grade Stem Cells: Protocols, Challenges, and Future Directions

This article provides a comprehensive guide to Good Manufacturing Practice (GMP) protocols for producing clinical-grade stem cells, tailored for researchers, scientists, and drug development professionals.

GMP Manufacturing for Clinical-Grade Stem Cells: Protocols, Challenges, and Future Directions

Abstract

This article provides a comprehensive guide to Good Manufacturing Practice (GMP) protocols for producing clinical-grade stem cells, tailored for researchers, scientists, and drug development professionals. It covers the foundational principles of GMP and its critical importance in cell therapy, details step-by-step methodological protocols for isolation, expansion, and characterization, addresses common troubleshooting and optimization strategies for manufacturing challenges, and explores validation frameworks and comparative analyses of different stem cell sources and culture systems. The content synthesizes current best practices and regulatory considerations to support the translation of stem cell research from the laboratory to clinical applications.

The Pillars of GMP: Building a Foundation for Clinical-Grade Stem Cell Production

Defining GMP and Its Critical Role in Cell Therapy Safety and Efficacy

Good Manufacturing Practice (GMP) represents a system for ensuring that products are consistently produced and controlled according to quality standards appropriate to their intended use. For cell therapies, classified as Advanced Therapy Medicinal Products (ATMPs) in Europe and as human cells, tissues, or cellular and tissue-based products (HCT/Ps) in the United States, compliance with GMP is mandatory for clinical application [1] [2]. The fundamental principle of GMP in this field is that safety and efficacy cannot be assured by final product testing alone but must be built into the manufacturing process through rigorous controls at every stage [3]. This is particularly critical for cell therapies, which consist of living, dynamic biological entities that cannot be sterilized or filtered at the final product stage, making process control paramount to patient safety [4].

Core GMP Principles for Cell Therapy Manufacturing

Quality Management Systems

A comprehensive Quality Management System (QMS) forms the foundation of GMP, encompassing all aspects of production from starting materials to final product release. This system requires that all activities are thoroughly documented and audited regularly to maintain product consistency and compliance with regulatory standards [3]. The QMS provides the framework for defining responsibilities, procedures, and controls to ensure that every product batch meets predefined specifications for quality, purity, and identity.

Facility and Environmental Control

GMP facilities for cell therapy must be designed to higher standards than conventional laboratories, with proper cleanroom classifications (Grade A, B, C, and D) based on air purity and particle counts [3] [4]. Environmental control, monitoring, and maintenance are critical to prevent contamination and determine operational efficiency. These facilities incorporate multi-level aseptic protection solutions, including clean rooms, laminar flow hoods, and closed cultivation systems to restrain airborne particles and avoid product contamination [4].

Process Validation and Control

All manufacturing processes must be validated and controlled according to standard operating procedures. This includes critical materials management, sample collection, processing, culturing, storage, quality control testing, and product release [3]. Process controls must demonstrate that the manufacturing process consistently yields a product meeting its quality attributes, with particular attention to aseptic processing since terminal sterilization is not possible for living cell products [1].

GMP-Compliant Manufacturing Processes and Protocols

Starting Materials and Reagents

A fundamental GMP requirement is the use of clinical-grade reagents free from animal contaminants. Traditional fetal bovine serum (FBS) has been largely replaced by xenogeneic-free alternatives such as human platelet lysate (hPL) or completely defined, serum-free media to eliminate risks of immunogenicity and transmission of infectious agents [5] [6] [1]. For example, a 2025 study demonstrated that FPMSCs (infrapatellar fat pad-derived mesenchymal stem cells) exhibited enhanced proliferation rates when cultured in MSC-Brew GMP Medium compared to standard MSC media, showing lower doubling times across passages [6].

Table 1: Comparison of GMP-Compliant Culture Media for MSC Expansion

| Media Formulation | Composition | Performance Results | Manufacturer |

|---|---|---|---|

| MSC-Brew GMP Medium | Animal component-free | Lower doubling times, higher colony formation | Miltenyi Biotec |

| MesenCult-ACF Plus Medium | Animal component-free | Supports MSC expansion and maintenance | StemCell Technologies |

| X-VIVO-15 | Serum-free with cytokines | Used in HSC gene therapy protocols | Lonza |

| Supplementation with human platelet lysate (hPL) | Human-derived growth factors | Superior to FBS for AT-MSC expansion in bioreactors | Various |

Automated Manufacturing Platforms

To ensure reproducibility and scale-up capability, automated closed-system platforms have been developed for GMP-compliant cell manufacturing, including the Quantum Cell Expansion System (Terumo BCT), CliniMACS Prodigy (Miltenyi Biotec), Cocoon Platform (Lonza), and Xuri Cell Expansion System W25 (Cytiva) [4]. These systems minimize manual open manipulations, reduce contamination risk, and provide a controlled environment for consistent cell expansion. For instance, the Quantum system reduced needed passages by half and open manipulations from 54,400 to 133 steps compared to flask-based propagation of BM-MSCs [4].

Table 2: Automated Platforms for GMP-Compliant Cell Manufacturing

| Platform | Technology | Scale/Capacity | Reported Output |

|---|---|---|---|

| Quantum Cell Expansion System | Hollow fiber bioreactor | 21,000 cm² (equiv. to 120 T-175 flasks) | 100-276 × 10⁶ BM-MSCs in 7-day expansion |

| CliniMACS Prodigy | Integrated cell processing with ACC | Culture vessel dependent | 29-50 × 10⁶ MSCs at P0 from mobilized blood |

| Cocoon Platform | Automated cell therapy manufacturing | Patient-scale | Designed for individualized therapies |

| Xuri W25 System | Wave-induced motion bioreactor | Scalable from 100 mL to 25 L | Compatible with suspension cell culture |

Protocol: GMP-Compliant MSC Expansion

The following protocol outlines the key steps for GMP-compliant expansion of mesenchymal stem/stromal cells (MSCs) based on current methodologies [6] [1]:

- Tissue Acquisition and Donor Screening: Source tissue (e.g., bone marrow, adipose tissue, umbilical cord) must be obtained with appropriate informed consent and donor eligibility determination, including screening for relevant communicable disease agents (RCDADs) [7] [1].

- Cell Isolation: Process tissue using enzymatic digestion (e.g., 0.1% collagenase for 2 hours at 37°C for adipose tissue) or density gradient separation in a closed system [5] [6].

- Primary Culture: Seed cells at density of 1,000-4,000 cells/cm² in GMP-compliant, animal component-free medium supplemented with appropriate growth factors [1].

- Cell Expansion: Culture cells to 80-90% confluency in multilayered flasks or bioreactors. Use animal component-free dissociation reagents for passaging. Limit population doublings to prevent senescence (typically <20 doublings) [1].

- Harvest and Formulation: Harvest cells using gentle detachment methods. Formulate in final infusion solution with appropriate cryoprotectant if needed.

- Cryopreservation: Cryopreserve in controlled-rate freezing system with defined cryoprotectant (e.g., DMSO at appropriate concentration) [4].

- Quality Control Testing: Perform comprehensive testing including viability, identity, potency, and sterility before product release.

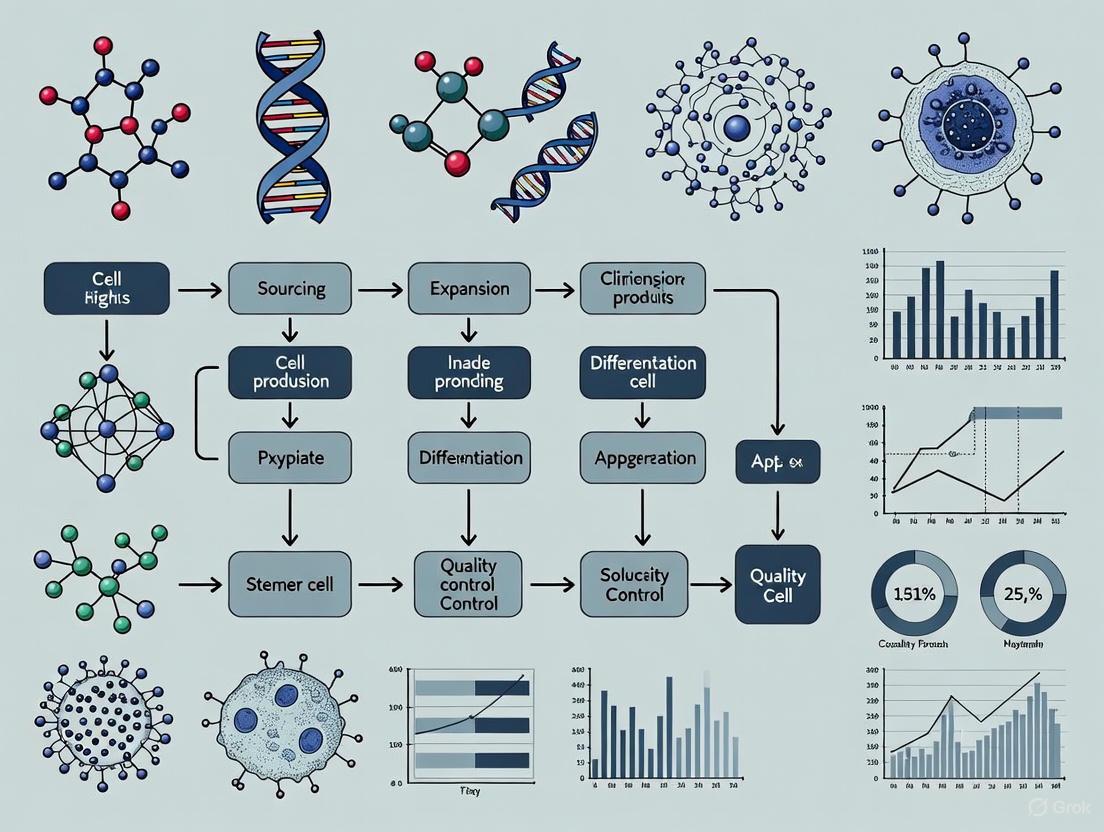

Diagram 1: GMP-Compliant MSC Manufacturing Workflow. This diagram outlines the critical stages in the production of clinical-grade mesenchymal stem/stromal cells, from tissue acquisition to final product release.

Quality Control and Product Characterization

Identity, Purity, and Potency Assays

According to International Society for Cellular Therapy (ISCT) guidelines, MSCs must demonstrate: (I) plastic adherence; (II) expression of CD105, CD73, and CD90 (>95% positive) and lack of expression of CD45, CD34, CD14, CD11b, CD79α, and HLA-DR (<2% positive); and (III) ability to differentiate into adipocytes, chondrocytes, and osteoblasts in vitro [4] [1]. Additional testing for immunomodulatory activity and genomic stability is recommended to ensure product safety and functionality [4]. A 2025 study on GMP-manufactured FPMSCs reported post-thaw viability >95% (exceeding the >70% requirement) and maintained sterility and stem cell marker expression even after 180 days of storage [6].

Safety Testing

Comprehensive safety testing includes sterility (bacteria, fungi), mycoplasma, endotoxin, and adventitious virus testing [6] [1]. In-process controls and final product testing must demonstrate absence of microbial contamination. Additional safety assessments may include karyotype analysis, in vitro potential for malignant transformation, and in vivo toxicity studies in immunodeficient animals, as demonstrated in a 2017 study of GMP-manufactured interferon γ-primed MSCs which showed no evidence of toxicity [8].

Regulatory Framework and Global Perspectives

GMP requirements for cell therapies vary across regulatory jurisdictions, though all emphasize a risk-based approach with increasing stringency through clinical development phases [2]. In the United States, the FDA regulates HCT/Ps under 21 CFR 1271, with phase 1 products reviewed under IND applications, while phase 2 and 3 products require manufacturing site registration [2]. In the European Union, the EMA requires manufacturing authorization for all clinical trial stages, with certification by a qualified person (QP) [2]. Canada takes a flexible risk-based approach, with GMP assessment conducted through Clinical Trial Application reviews for all development phases [2].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Essential GMP-Compliant Reagents for Cell Therapy Manufacturing

| Reagent/Material | Function | GMP-Compatible Examples |

|---|---|---|

| Cell Culture Media | Supports cell growth and expansion | MSC-Brew GMP Medium, MesenCult-ACF Plus, X-VIVO-15 |

| Dissociation Reagents | Cell passaging and harvesting | TrypLE Select, TrypZean, GMP-grade collagenase |

| Culture Supplements | Enhance growth and maintain cell properties | Human platelet lysate (e.g., PLT-Max, Stemulate) |

| Cryopreservation Media | Maintain cell viability during frozen storage | Defined cryoprotectant solutions with DMSO |

| Cell Separation Reagents | Isolate target cell populations | Ficoll-Paque PREMIUM, CliniMACS reagents |

| Process Additives | Improve efficiency of specific steps | LentiBOOST, protamine sulfate (for transduction) |

GMP implementation is fundamental to ensuring the safety and efficacy of cell-based therapies. By establishing robust quality systems, employing standardized manufacturing processes with defined reagents, and implementing comprehensive quality control testing, developers can deliver consistent, high-quality cell products for clinical applications. The field continues to evolve with advancements in automated platforms, improved culture systems, and harmonized regulatory approaches that collectively support the translation of promising cell therapies from research to clinical practice.

Core Components of a GMP Quality Management System (QMS)

A Good Manufacturing Practice (GMP)-compliant Quality Management System (QMS) is a structured framework of documented procedures and controls essential for the consistent production of clinical-grade stem cell products. For researchers developing Advanced Therapy Medicinal Products (ATMPs), implementing a robust QMS is not merely a regulatory formality but a fundamental component of ensuring product safety, identity, purity, potency, and efficacy. This application note details the core components of a GMP QMS, provides practical protocols for implementation within stem cell research, and discusses emerging regulatory considerations for decentralized manufacturing.

The transition of stem cell therapies from research to clinical application is governed by stringent regulatory frameworks. The European Commission's ATMP Regulation classifies stem-cell-based products for human use as pharmaceuticals, bringing them under the purview of GMP guidelines [9]. Unlike conventional drugs, stem cell therapies comprise living, fragile biological entities that cannot be standardized identically to a chemical pill, making a robust, risk-based QMS paramount for controlling variability and ensuring patient safety [9].

A GMP-compliant QMS provides the foundation for consistent production, risk mitigation, and regulatory compliance throughout the product lifecycle. Its core principles are often summarized as the "Five Ps": People, Processes, Procedures, Products, and Premises [10]. Adherence to these principles minimizes risks such as contamination, mislabeling, and process failures, which are critical when manufacturing patient-specific autologous therapies [10] [11].

Core Components of a GMP-Compliant QMS

A comprehensive QMS for clinical-grade stem cell manufacturing is built upon several interconnected pillars. The table below summarizes the fundamental components and their primary objectives.

Table 1: Core Components of a GMP-Compliant QMS for Stem Cell Manufacturing

| QMS Component | Primary Objective | Key Documentation & Outputs |

|---|---|---|

| Quality Management | To oversee the entire system, ensuring product quality and facilitating continual improvement [12] [13]. | Quality Manual, Quality Policy, Management Review Records, Quality Risk Management (QRM) files [14] [13]. |

| Personnel & Training | To ensure all staff are qualified, trained, and adhere to hygiene protocols to prevent errors and contamination [15] [13]. | Organizational Charts, Job Descriptions, Training Plans & Matrices, Training Records, Competency Assessments, Hygiene SOPs [15] [13]. |

| Premises & Equipment | To provide and maintain a controlled environment and qualified equipment suitable for stem cell manufacturing [15] [16]. | Facility & Cleanroom Validation Records, Equipment Logs, Calibration & Maintenance Records, Cleaning Validation Reports [15] [16]. |

| Documentation & Record Keeping | To provide documented evidence that all GMP activities have been performed correctly. "If it isn't documented, it didn't happen." [15] | Standard Operating Procedures (SOPs), Batch Manufacturing Records (BMRs), Deviation Reports, Logbooks [12] [15]. |

| Process & Procedure Control | To ensure manufacturing processes are defined, validated, and controlled to consistently yield products meeting specifications [10] [15]. | Validated Manufacturing Protocols, Process Flow Diagrams, Critical Process Parameter (CPP) monitoring records [15]. |

| Raw Material & Supplier Management | To guarantee the quality of ancillary materials (AMs) and starting materials, which directly impacts final product safety and efficacy [17] [15]. | Approved Supplier List, Supplier Audit Reports, Raw Material Specifications, Incoming Inspection Records [17] [15]. |

| Quality Control (QC) & Testing | To monitor, sample, and test raw materials, in-process samples, and final products to ensure they meet quality standards [15] [13]. | QC Test Methods & Protocols, Specifications, Certificates of Analysis (CoA), Stability Study Data [13]. |

| Deviations, CAPA, and Change Control | To manage unplanned events, identify root causes, implement corrective actions, and control modifications to validated systems [12] [15]. | Deviation Reports, CAPA Records, Change Control Requests, Effectiveness Verification Reports [12] [15]. |

The following workflow diagram illustrates the logical relationships and interdependencies between these core components within an effective QMS.

Diagram 1: GMP QMS Component Relationships

Practical Implementation and Experimental Protocols

Protocol: Ancillary Material (AM) Qualification for Stem Cell Culture

The quality of ancillary materials (AMs)—such as cell isolation reagents, culture media, and cytokines—is widely recognized as having a direct impact on the safety and efficacy of the final cell therapy product [17]. Their qualification is a critical GMP activity.

1. Principle To establish the source, identity, purity, biological safety, and general suitability of an AM for its intended use in the manufacturing process of a clinical-grade stem cell product, following a risk-based approach as guided by USP <1043> and Ph. Eur. 5.2.12 [17].

2. Materials and Reagents Table 2: Research Reagent Solutions for AM Qualification

| Item | Function / Purpose | Critical Quality Attribute |

|---|---|---|

| Ancillary Material (AM)(e.g., GMP-grade FBS) | Provides essential growth factors and nutrients for stem cell expansion. | Identity, Purity, Sterility, Viral Safety, Endotoxin Level. |

| Characterization Assay Kits(e.g., Flow Cytometry, ELISA) | Confirm AM identity and detect specific impurities or contaminants. | Specificity, Accuracy, Precision. |

| Sterility Testing Media(e.g., Fluid Thioglycollate Medium) | Detects microbial contamination in the AM. | Growth Promotion. |

| Endotoxin Testing Kit(e.g., LAL Assay) | Quantifies bacterial endotoxin levels. | Confirmed validity and sensitivity. |

| Cell Line for Bio-functionality Testing(e.g., Reference hPSC Line) | Assesses the impact of the AM on stem cell phenotype and function. | Stable Karyotype, Validated Phenotype. |

3. Methodology

- Step 1: Supplier Qualification & Documentation Review. Audit the AM supplier or request a GMP Master File from them. Obtain and review the Certificate of Analysis (CoA) for the specific lot, and ensure full traceability of the material's origin [17] [15].

- Step 2: Identity and Purity Testing. Perform testing to confirm the AM's identity (e.g., using spectroscopic or chromatographic methods) and purity. Test for impurities and contaminants relevant to the source (e.g., bovine viruses in serum, host cell proteins in recombinant proteins) [17].

- Step 3: Safety Testing. Conduct sterility testing (according to pharmacopoeial methods), mycoplasma testing (if applicable), and endotoxin testing. The endotoxin limit should be justified based on the final product's route of administration and dose [9].

- Step 4: Performance/Bio-functionality Testing. Using a well-characterized stem cell line, evaluate the AM's performance against a predefined reference standard or a research-grade equivalent. Key parameters include:

- Cell Viability and Growth Kinetics: Perform daily cell counts and viability assays (e.g., Trypan Blue exclusion) over a minimum of three passages.

- Phenotype Maintenance: Analyze stem cell markers (e.g., Tra-1-60, SSEA-4 for pluripotency) via flow cytometry at each passage.

- Differentiation Potential: Conduct directed differentiation assays (e.g., to ectoderm, mesoderm, and endoderm lineages) to confirm the AM does not impair pluripotency.

- Step 5: Stability Testing. Establish the AM's shelf-life under recommended storage conditions by repeating critical identity, purity, safety, and functionality tests at predetermined time points.

4. Data Analysis and Acceptance Criteria Compare all test results against predefined specifications. The AM lot is deemed qualified only if it meets all acceptance criteria for identity, purity, safety, and functionality. Any out-of-specification (OOS) result must be investigated through a formal deviation and CAPA process.

Protocol: Process Validation for Stem Cell Expansion

Process validation provides documented evidence that the stem cell expansion process consistently produces a product meeting its predetermined quality attributes.

1. Principle To demonstrate, through rigorous and documented experimentation, that the proposed manufacturing process for stem cell expansion is robust, reproducible, and capable of consistently yielding a product that complies with its quality target product profile (QTPP) [15].

2. Methodology (Three-Lot Validation Approach)

- Stage 1: Process Design. Define the QTPP and identify Critical Quality Attributes (CQAs) of the final cell product (e.g., viability, identity, potency, sterility). Using risk assessment, link CQAs to Critical Process Parameters (CPPs) of the expansion process (e.g., seeding density, media exchange frequency, passaging method, oxygen tension). Design a scalable process and establish control strategies for these CPPs.

- Stage 2: Process Qualification.

- Equipment Qualification: Ensure all equipment (e.g., bioreactors, incubators, centrifuges) used in the process has undergone Installation, Operational, and Performance Qualification (IQ/OQ/PQ) [15].

- Process Performance Qualification (PPQ): Execute a minimum of three consecutive consecutive full-scale GMP batches using the defined process and the qualified equipment. The batches must be manufactured by trained personnel in the GMP facility using qualified AMs.

- Stage 3: Continued Process Verification. Implement ongoing monitoring of the validated process during routine production to ensure it remains in a state of control.

3. Data Collection and Acceptance Criteria During PPQ, extensive data must be collected for each batch. The table below outlines key validation data points.

Table 3: Key Data Points for Stem Cell Expansion Process Validation

| Process Stage | Parameter Monitored | Acceptance Criteria |

|---|---|---|

| Starting Material | Donor Cell Viability, Identity | Viability > X%, Confirmed donor identity. |

| In-Process Controls | Cell Doubling Time, Metabolite Levels (e.g., Glucose), Phenotype (Flow Cytometry) | Consistent doubling time, Metabolite levels within range, Phenotype purity > Y%. |

| Final Product Release | Total Cell Number, Viability, Identity, Potency, Sterility, Endotoxin | Cell number > Z, Viability > 80%, Identity confirmed, Potency assay met, Sterile, Endotoxin < threshold. |

Special Considerations for Stem Cell Therapies and Emerging Trends

Navigating the Regulatory Landscape for Ancillary Materials

A common challenge for researchers is the qualification of AMs not manufactured under GMP. It is a misconception that only "GMP-grade" AMs can be used in clinical trials. Regulatory guidance allows for a risk-based approach, particularly for early-phase trials [17]. The responsibility for AM qualification lies with the therapy manufacturer, who can leverage supplier documentation (e.g., ISO 13485 certification) and perform additional testing to establish suitability [17]. Claims of "cell-therapy-grade" are market-driven and not a recognized regulatory standard [17].

The Rise of Decentralized Manufacturing

For autologous stem cell therapies, decentralized manufacturing at or near the point of care (POCare) is an emerging paradigm to overcome logistical hurdles and reduce costs [11]. This model involves manufacturing in multiple, geographically dispersed sites (e.g., academic health centers) under the oversight of a central "Control Site" [11]. The Control Site holds the regulatory license, maintains the central product file, and ensures consistency and comparability across the entire network through a robust, integrated QMS [11]. Regulatory bodies like the MHRA, FDA, and EMA are developing frameworks to accommodate this shift, emphasizing the need for automated, closed-system technologies to minimize process variability [11].

Implementing a comprehensive, GMP-compliant QMS is a non-negotiable requirement for translating stem cell research from the laboratory to the clinic. Its core components—from quality management and personnel training to meticulous documentation and robust process control—form an interdependent ecosystem designed to ensure product quality and patient safety. As the field evolves with trends like decentralized manufacturing, the principles of GMP and a robust, adaptable QMS will remain the cornerstone of safe and effective stem cell therapy development.

Understanding Regulatory Landscapes and Global Standards (FDA, EMA, ISO)

The transition of stem cell-based therapies from research to clinical application is a complex process governed by stringent regulatory frameworks. These frameworks, established by bodies like the U.S. Food and Drug Administration (FDA), the European Medicines Agency (EMA), and the International Organization for Standardization (ISO), ensure that cell therapies are safe, efficacious, and of high quality. For researchers and drug development professionals, navigating this multifaceted regulatory landscape is critical for the successful development and approval of clinical-grade stem cell products. This document outlines the core principles of Good Manufacturing Practices (GMP), risk management, and key regulatory requirements, providing a foundation for compliance in stem cell research and manufacturing.

Core Regulatory and Standardization Bodies

United States Food and Drug Administration (FDA)

The FDA regulates stem cell products primarily as Human Cells, Tissues, and Cellular and Tissue-Based Products (HCT/Ps) under 21 CFR Part 1271 [18]. The level of regulatory oversight is tiered and risk-based. Products that are minimally manipulated and intended for homologous use do not require pre-market approval. However, most stem cell products, particularly those that are more than minimally manipulated or intended for non-homologous use, are regulated as biological products and require an Investigational New Drug (IND) application for clinical trials and eventual Biologics License Application (BLA) approval [18].

A key requirement is that establishments involved in the manufacture of HCT/Ps must register with the FDA and list their products [19]. The FDA also enforces Current Good Manufacturing Practice regulations to ensure quality [20]. In January 2025, the FDA issued new draft guidance clarifying requirements for in-process controls under 21 CFR § 211.110, supporting the use of advanced manufacturing technologies while emphasizing a risk-based approach and the need for in-process testing to ensure batch uniformity [21].

Table: Key FDA Regulations for Stem Cell Products

| Regulation | Title | Key Focus |

|---|---|---|

| 21 CFR Part 1271 | Human Cells, Tissues, and Cellular and Tissue-Based Products (HCT/Ps) | Registration, listing, donor eligibility, and current good tissue practice (GTP) |

| 21 CFR Part 211 | Current Good Manufacturing Practice for Finished Pharmaceuticals | GMP requirements for drug products, including quality control and facility controls |

| 21 CFR Part 600 | Biological Products: General | Additional requirements for biological products |

International Organization for Standardization (ISO)

ISO standards provide internationally recognized frameworks for quality and risk management. For medical devices, including some combination products or equipment used in cell therapy manufacturing, ISO 14971 specifies a process for risk management throughout the entire product lifecycle [22]. The standard requires manufacturers to identify hazards, estimate and evaluate associated risks, implement risk control measures, and monitor the effectiveness of controls [23].

Another critical standard is ISO 13485, which specifies requirements for a Quality Management System (QMS) for organizations involved in the design and manufacture of medical devices. A QMS certified to ISO 13485 demonstrates a commitment to consistent quality and meeting regulatory requirements [17]. Furthermore, ISO 9001 defines requirements for a general QMS, demonstrating an organization's ability to consistently provide products that meet customer and regulatory requirements [17].

European Medicines Agency (EMA) and Other Global Bodies

The EMA regulates stem cell therapies through the Advanced Therapy Medicinal Products (ATMP) regulation. While the provided search results focus on FDA and ISO, it is important to note that the EMA's requirements are equally rigorous. The European Pharmacopoeia (Ph. Eur.) provides critical guidance on raw materials, which are referred to as ancillary materials in cell therapy manufacturing [17]. Furthermore, the International Society for Stem Cell Research (ISSCR) provides influential, regularly updated guidelines for stem cell research and clinical translation. The ISSCR emphasizes fundamental principles such as integrity of the research enterprise, primacy of patient welfare, and transparency [24].

GMP Manufacturing Protocols for Clinical-Grade Stem Cells

Ancillary Material (AM) Qualification

Ancillary Materials are components, reagents, and materials used during the manufacture of a cell therapy product but not intended to be part of the final product [17]. Examples include cell isolation reagents, culture media, and cryopreservation media. The quality of AMs directly impacts the safety, efficacy, and consistency of the final cell therapy product.

Manufacturers must qualify all AMs, a process of establishing the source, identity, purity, biological safety, and general suitability for use [17]. This follows a risk-based approach, as there is no single "cell-therapy grade" universally mandated. Guidance can be found in United States Pharmacopeia (USP) Chapter <1043> and Ph. Eur. General Chapter 5.2.12 [17].

Table: Ancillary Material Qualification Framework

| Quality Attribute | Description | Common Test Methods |

|---|---|---|

| Identity | Confirmation of the material's identity | Certificate of Analysis (CoA), spectroscopic methods |

| Purity | Freedom from contaminants (e.g., endotoxins, bioburden) | LAL testing, microbial enumeration, sterility testing |

| Potency | Biological activity relevant to its function | Functional assays, growth promotion tests |

| Safety | Freedom from adventitious agents | Viral safety testing, in vitro/vivo adventitious agent tests |

Risk Management in Manufacturing

A proactive risk management process, as defined by ISO 14971, is integral to GMP compliance. The process involves risk analysis, evaluation, control, and production, and post-production monitoring [22]. Risk control options for medical devices, which can be analogously applied to manufacturing processes, include [22]:

- Inherent safety by design: e.g., using closed-system processing to reduce contamination risk.

- Protective measures: e.g., incorporating in-process safety testing and controls.

- Information for safety: e.g., providing comprehensive documentation and standard operating procedures (SOPs).

This risk-based approach is also echoed in the FDA's cGMP regulations and recent guidance, which allows for flexibility in defining "significant phases" for in-process testing, provided the determination is justified by scientific rationale [21].

Current GMP Guidelines and Advanced Manufacturing

The FDA's cGMP regulations (21 CFR Parts 210 and 211) establish the minimum standards for methods, facilities, and controls used in drug manufacturing [20]. A significant recent development is the FDA's January 2025 draft guidance on complying with 21 CFR § 211.110, which addresses in-process controls and supports the adoption of advanced manufacturing technologies [21].

Advanced manufacturing includes innovative technologies that enhance drug quality and production, such as continuous manufacturing and real-time quality monitoring using Process Analytical Technology (PAT) [21]. The guidance advises that while process models are beneficial, they should be paired with in-process testing or examination, as the FDA has not yet identified any model that can reliably adapt to all unplanned disturbances during production [21].

Experimental Protocols for Regulatory Compliance

Protocol: Qualification of a New Ancillary Material (Serum-Free Medium)

1.0 Objective To establish the safety, identity, purity, and functional performance of a new serum-free medium for use in the manufacturing of a clinical-grade mesenchymal stem cell (MSC) product.

2.0 Scope This protocol applies to all raw materials intended for use as Ancillary Materials in GMP-compliant cell therapy manufacturing.

3.0 Materials and Equipment

- Test article: Serum-free medium (SFM) batch.

- Reference standard: A previously qualified medium or a research-grade equivalent for comparison.

- Cells: Master Cell Bank of human MSCs.

- Equipment: CO2 incubator, biosafety cabinet, cell counter, flow cytometer, endotoxin testing kit, sterility test kits.

4.0 Methodology 4.1 Identity Testing: Compare the physical appearance (color, clarity) and osmolality of the test article against the manufacturer's specifications. 4.2 Purity and Safety Testing:

- Sterility Test: Inoculate the test article into fluid thioglycollate medium and soybean-casein digest medium per USP <71>.

- Mycoplasma Test: Perform a validated PCR-based or culture-based method.

- Endotoxin Test: Use a Limulus Amebocyte Lysate (LAL) assay to ensure levels are below the specified limit (e.g., <0.5 EU/mL). 4.3 Functional Performance Testing:

- Cell Growth and Proliferation: Seed MSCs at a defined density in the test SFM and a control medium. Perform cell counts and viability assessments (e.g., via Trypan Blue exclusion) over 3-5 passages. Calculate population doubling times.

- Cell Phenotype Maintenance: After expansion in the test SFM, analyze cells by flow cytometry for standard MSC surface markers (CD73, CD90, CD105) and absence of hematopoietic markers (CD34, CD45).

- Differentiation Potential: Differentiate expanded MSCs into adipocytes, osteocytes, and chondrocytes using standard differentiation kits. Assess differentiation via staining (Oil Red O, Alizarin Red, Alcian Blue, respectively).

5.0 Acceptance Criteria The test article meets all acceptance criteria if it passes sterility and mycoplasma tests, has endotoxin levels below the specified limit, supports MSC expansion with stable viability and phenotype, and maintains trilineage differentiation potential comparable to the control.

Protocol: Risk Analysis for a Cell Processing Step (Enzymatic Passaging)

1.0 Objective To perform a risk analysis for the enzymatic passaging step in MSC manufacturing to identify and control potential hazards.

2.0 Methodology (per ISO 14971)

- Risk Analysis: Identify foreseeable hazards associated with using a recombinant trypsin replacement enzyme.

- Hazard: Residual enzyme activity in the final cell product.

- Hazardous Situation: Administration of the cell product to a patient, leading to unintended tissue digestion or immune reaction.

- Risk Evaluation: Estimate the severity of harm (e.g., moderate tissue damage) and probability of occurrence. The initial risk level is deemed unacceptable and requires mitigation.

- Risk Control: Implement a risk control measure.

- Measure: Introduce a defined, validated washing step with a serum-containing medium or a specific enzyme inhibitor after cell detachment to ensure no residual enzyme activity remains.

- Verification: Perform a validated assay to detect and quantify residual enzyme activity in the final cell product to verify the effectiveness of the washing step.

3.0 Output A risk management file entry documenting the hazard, initial risk assessment, the implemented control measure, and the verification data confirming residual enzyme levels are below the acceptable limit.

The Scientist's Toolkit: Research Reagent Solutions

Navigating the regulatory requirements for ancillary materials is a critical task. The following table details key material categories and their functions in stem cell manufacturing workflows.

Table: Essential Materials for Clinical-Grade Stem Cell Manufacturing

| Material Category | Key Function | Regulatory & Quality Considerations |

|---|---|---|

| Cell Isolation Kits | To isolate specific cell types (e.g., MSCs, HSCs) from tissue or blood sources. | Components (e.g., antibodies) must be qualified. Prefer closed-system, GMP-manufactured kits to reduce contamination risk and streamline validation [17]. |

| Cell Culture Media | To support the growth, expansion, and maintenance of stem cells in vitro. | Formulation must be consistent and free of animal-derived components (xeno-free). Supplier should provide a detailed TSE/BSE statement and Certificate of Analysis [17]. |

| Cell Dissociation Reagents | To detach adherent cells from culture surfaces for passaging or harvest. | Enzymatic reagents must be tested for sterility and purity. A validated washing/inactivation step is critical to ensure no residual activity in the final product. |

| Cryopreservation Media | To preserve cell products at ultra-low temperatures for storage and transport. | Formulation should use defined, clinically acceptable cryoprotectants (e.g., DMSO). The final DMSO concentration in the product must be safe for human administration. |

| Cell Differentiation Kits | To direct stem cells toward specific lineages (e.g., cardiomyocytes, neurons). | Kit components must be qualified for clinical use. The differentiation process must be robust, reproducible, and yield a well-characterized cell population. |

Workflow and Relationship Visualizations

Regulatory Pathway for a Stem Cell Product

The following diagram outlines the key stages and major regulatory milestones in the development of a clinical-grade stem cell therapy.

Ancillary Material Qualification Workflow

This flowchart details the step-by-step process for qualifying an ancillary material for use in GMP manufacturing.

The Critical Importance of Ancillary Material (AM) Qualification and Risk Assessment

The transition of stem cell research from the laboratory to the clinic represents one of the most significant challenges in modern regenerative medicine. Within the context of Good Manufacturing Practice (GMP) for clinical-grade stem cells, ancillary materials—reagents and components used in manufacturing but not intended for inclusion in the final product—present a critical variable affecting both product safety and efficacy [17]. The qualification and risk assessment of these materials constitute a foundational element of quality assurance for Advanced Therapeutic Medicinal Products (ATMPs) [25]. Unlike traditional pharmaceuticals, cell and gene therapy products cannot undergo terminal sterilization, making the quality and safety of every input material paramount to the final product's therapeutic profile [26]. This application note details the structured framework necessary for AM qualification, providing both the regulatory context and practical protocols to ensure compliance and patient safety throughout the clinical development lifecycle.

Regulatory Framework for Ancillary Materials

Global Guidelines and Definitions

The regulatory landscape for AMs is defined by several key pharmacopeia documents and guidelines, which, while not legally binding, establish the current industry standards for quality and safety. A fundamental challenge lies in the varied terminology, where "ancillary materials" (US) and "raw materials" (EU) often refer to the same components [17] [25]. These materials include cell isolation reagents, culture and cryopreservation media, cytokines, growth factors, and disposable plasticware [17].

Globally, there is no mandated "cell therapy grade" for AMs, and claims of such are market-driven rather than reflecting an accepted regulatory standard [17]. Instead, regulators expect a risk-based qualification strategy tailored to the specific material's use and the stage of clinical development [17] [26]. The following table summarizes the core regulatory documents governing AMs.

Table 1: Key Global Regulatory Guidelines for Ancillary Materials

| Guideline | Issuing Body | Geographic Scope | Core Focus |

|---|---|---|---|

| USP <1043> "Ancillary Materials for Cell, Gene and Tissue-Engineered Products" [25] [26] | United States Pharmacopeia | Primarily US, globally influential | Risk classification system and general qualification guidance for AMs. |

| Ph. Eur. 5.2.12 "Raw Materials for the Production of Cell-Based and Gene Therapy Medicinal Products" [17] [25] | European Directorate for the Quality of Medicines & HealthCare | European Union | Stringent requirements for biological origin materials, production within a suitable QMS, and sterility. |

| IPRP Report "General Considerations for Raw Materials..." [25] | International Pharmaceutical Regulators Programme | International (including US, EU, Japan, Canada) | Quality Management Systems, supplier approval, and transparency of origin and traceability. |

| ISO 20399:2022(E) [25] | International Organization for Standardization | International | Framework outlining the roles and responsibilities of AM suppliers and users. |

The Risk-Based Approach to AM Qualification

A risk-based approach (RBA) is the cornerstone of AM management, aligning with fundamental GMP principles and regulatory guidance such as ICH Q9 [27]. This systematic process involves identifying potential hazards, assessing their impact, and implementing appropriate control measures to focus resources on areas of highest risk to product quality and patient safety [17] [27].

USP <1043> provides a widely adopted framework, categorizing AMs into a four-tiered risk classification to guide the level of qualification needed [26]. The classification is based on the material's source, complexity, and criticality to the manufacturing process [25] [26].

Table 2: USP <1043> Ancillary Material Risk Classification Tier

| Tier | Risk Level | Description | Example Materials |

|---|---|---|---|

| 1 | Lowest | Materials of high purity with a well-defined chemical structure, low risk of adventitious agents. | Inorganic salts, simple buffers [26]. |

| 2 | Low | Materials of known structure, but with potential for minor impurities; often not of human or animal origin. | Sugares, amino acids, recombinant proteins [25] [26]. |

| 3 | Moderate | Materials of unknown structure or materials of animal or human origin that have been purified. | Growth factors, cytokines, human serum albumin [25] [26]. |

| 4 | Highest | Materials of human or animal origin with minimal processing, presenting a high risk of contamination. | Serum, trypsin, primary cells [26]. |

The following workflow diagram illustrates the systematic process for risk assessment and management of AMs.

Implementing an AM Qualification Program

Material Qualification and Supplier Management

The qualification process translates risk assessment into actionable controls. The ultimate responsibility for AM qualification lies with the cell therapy manufacturer, but a close partnership with the supplier is essential for efficiency [17]. The process involves several key steps:

Supplier Qualification and Quality Agreements: Conduct thorough due diligence on potential AM suppliers. This should include, where possible, an on-site audit of the manufacturing facility to assess their Quality Management System (QMS) [26]. Establishing a robust quality agreement is critical. This agreement should mandate advanced notification of any changes to the AM, as such changes can significantly impact the manufacturing process and final product [17] [26].

Documentation and Traceability: Request and maintain comprehensive regulatory support documentation from the supplier. Essential documents include:

- Certificate of Analysis (CoA): Verifies product identity, purity, and quality against specifications.

- Certificate of Compliance (CoC): States adherence to a quality standard like GMP or ISO.

- TSE/BSE Statement: Confirms the material is free from transmissible spongiform encephalopathy agents.

- Certificate of Origin (COO): Provides traceability for materials, especially those of human or animal origin [25] [26]. For clinical phases, suppliers like ACROBiosystems offer extensive Level 2 documentation packages exceeding 1000 pages, which include detailed analytical method validation reports and Standard Operating Procedures (SOPs) [25].

Material Sourcing and Control: For critical materials, managing the supply source is vital. A single-source material requires maintaining a safety stock and a formal supply agreement to ensure continuity. If multiple sources are available, they must be evaluated and qualified early in development [26]. All materials must be stored, tracked, and labeled correctly to prevent mix-ups and ensure their quality is maintained until use.

The Scientist's Toolkit: Essential Research Reagent Solutions

Selecting the appropriate grade of materials is a key decision in the translational pathway. The following table outlines common reagent categories and examples used in GMP-compliant stem cell research and manufacturing.

Table 3: Essential Reagent Solutions for Clinical-Grade Stem Cell Research

| Reagent Category | Function | GMP-Grade Example(s) |

|---|---|---|

| Basal Media | Provides essential nutrients for cell growth and maintenance. | Essential 8 [28], StemFit Basic03/Basic04 CT [29], Nutristem [28] |

| Differentiation Media | Directs pluripotent stem cells toward specific lineages. | StemFit for Differentiation [29], StemXVivo Chondrogenic Media [30] |

| Growth Factors/Cytokines | Signalling molecules that control cell fate, proliferation, and differentiation. | GMP FGF, GMP EGF (Bio-techne) [28], bFGF, Activin A [29] |

| Cell Dissociation Reagents | Enzymatic or non-enzymatic passaging of adherent cells. | StemPro Accutase [28], GMP EDTA [28] |

| Extracellular Matrices (ECM) | Provides a substrate for cell attachment and growth. | Recombinant Vitronectin (VTN-N) [28], Laminin-521 (LN521) [28] |

| Small Molecule Inhibitors | Enhances cell survival after passaging or thawing. | GMP ROCK inhibitor (Revitacell) [28] |

| Serum-Free Supplements | Chemically defined replacements for fetal bovine serum (FBS). | CTS B27, CTS N2 [28] |

Case Study: GMP-Grade Neural Progenitor Derivation

Experimental Protocol

The following protocol, adapted from a published study, demonstrates the practical application of AM qualification in deriving long-term neuroepithelial-like stem cells (lt-NES) from clinical-grade human embryonic stem cells (hESCs) under GMP-compliant conditions [28].

Objective: To robustly derive and bank lt-NES cells from multiple clinical-grade hESC lines using exclusively GMP-grade ancillary materials.

Materials:

- Cell Lines: Clinical-grade hESC lines (e.g., MasterShef series from UK Stem Cell Bank) [28].

- Culture Vessels: Aggrewell 800 plates (Stem Cell Technologies), standard cell culture-treated plates [28].

- Key GMP-Grade Reagents: Refer to Table 3 in Section 3.2 for specific examples used in this workflow.

Methodology:

hESC Pre-Culture: Maintain hESCs on recombinant VTN-N Vitronectin in GMP Essential 8 medium. Passage using GMP EDTA, ensuring colonies are detached as small clumps [28].

Embryoid Body (EB) Formation:

- Dissociate undifferentiated hESCs to single cells using StemPro Accutase.

- Resuspend 3 x 10^6 cells in 1.5 mL of Essential 6 medium supplemented with Revitacell.

- Transfer the cell suspension to one well of an Aggrewell 800 plate pre-treated with E6 + Revitacell. Centrifuge at 2000×g to aggregate cells.

- After 24 hours, carefully replace the medium entirely with fresh E6. Perform a 50% medium change daily from day 2 to day 4 [28].

Neural Induction and Rosette Selection:

- On day 5, detach EBs from the Aggrewell plate and collect them using a reversible strainer.

- Plate EBs onto a culture dish coated with GMP-grade Laminin 521 (10 µg/mL in DPBS+/+).

- Culture in GMP N2 media (CTS DMEM-F12 + CTS N2 + CTS B27 + Glutamax), changing the media daily for 3-5 days to induce neural differentiation.

- Once neural rosettes appear, select them using the STEMdiff Neural Rosette Selection Reagent for 45-60 minutes at 37°C. Gently detach and collect the purified rosette clusters [28].

lt-NES Establishment and Expansion:

- Centrifuge the collected rosettes and resuspend in N2 media supplemented with 10 ng/mL each of GMP FGF and GMP EGF (N2 EF media) plus Revitacell.

- Plate at high density onto Laminin 521-coated plates (e.g., one well of a 48-well plate). Critical Step: High cell density is required for survival and proliferation.

- Feed daily with GMP N2 EF media. Once confluent, passage using accutase for 1 minute at 37°C, and continue expanding with a split ratio of approximately 1:1 [28].

The following workflow diagram summarizes this GMP-grade differentiation protocol.

Outcome and Analysis

This GMP-adapted protocol successfully demonstrated the robust and reproducible derivation of lt-NES from several clinical-grade hESC lines [28]. The resulting lt-NES cells were multipotent, bankable, and karyotypically stable, retaining the capacity for high neurogenic potential and differentiation into various neuronal subtypes [28]. This case highlights the feasibility of translating research protocols to GMP-compliant processes by systematically replacing research-grade reagents with qualified GMP-grade AMs, thereby creating a flexible tool to speed up translation to clinic for neurological therapies.

The path from research to clinically applicable stem cell therapies is paved with rigorous quality control, at the heart of which lies the meticulous qualification and risk assessment of ancillary materials. A successful strategy is not defined by simply selecting "GMP-grade" labels but by implementing a holistic, risk-based program that encompasses thorough supplier qualification, comprehensive documentation, and stringent material control. As the regulatory landscape evolves, the principles outlined in this document—alignment with global pharmacopeia standards, proactive risk management, and robust supplier partnerships—provide a sustainable framework for ensuring the safety, quality, and efficacy of revolutionary stem cell-based medicines.

In the field of clinical-grade stem cell research, the controlled environment is as critical as the biological protocol itself. Current Good Manufacturing Practice (cGMP) cleanrooms provide the foundational infrastructure necessary to ensure that advanced therapeutic medicinal products (ATMPs) are manufactured with the highest standards of safety, quality, and efficacy. These specialized environments are designed to maintain extremely low levels of airborne particles and microbial contamination, thereby protecting sensitive cell cultures from pollutants that could compromise their integrity [31]. For stem cell therapies, where the product is often both the treatment and the drug, the cleanroom facility becomes an extension of the manufacturing process, directly influencing the critical quality attributes of the final cellular product.

The transition from research-grade to clinically-applicable stem cell products necessitates adherence to cGMP standards, which differ from basic Good Manufacturing Practices (GMP) through their emphasis on employing current, state-of-the-art technologies and systems [32]. Regulatory bodies including the U.S. Food and Drug Administration (FDA) and European Medicines Agency (EMA) mandate cGMP compliance for stem cell products intended for human administration, with facilities subject to rigorous inspection and validation requirements [33]. This application note details the essential facility requirements, design principles, and validation protocols for establishing cGMP-compliant cleanrooms specifically tailored to the unique demands of clinical-grade stem cell research and manufacturing.

Core Principles of cGMP Cleanroom Design

Classification and Zoning

cGMP cleanrooms operate on a zoning principle that establishes progressively cleaner environments from peripheral areas to critical processing zones. This graded approach to contamination control is fundamental to protecting stem cell products during their most vulnerable processing stages.

- Grade Definitions: Cleanrooms are classified into grades A-D according to EU GMP guidelines, corresponding to ISO 14644 classes 5-8 [34]. Grade A (ISO 5) represents the highest cleanliness level for high-risk operations like open-container processing and aseptic filling, while Grades B-D provide background environments with decreasing stringency [34].

- Activity-Specific Zoning: Stem cell manufacturing processes must be mapped to appropriate cleanroom classifications. Hematopoietic stem cell gene therapy requires aseptic processing in Grade A environments [35], while the derivation and expansion of neural progenitor cells may be conducted in Grade B or C backgrounds [28].

- Dynamic Classifications: cGMP guidelines recognize two distinct operational states: "at rest" (unoccupied but operational) and "in operation" (occupied with processes underway) [36]. This distinction acknowledges that personnel presence and activities inevitably impact environmental conditions.

Table 1: cGMP Cleanroom Classifications and Applications in Stem Cell Research

| EU GMP Grade | ISO Classification | Maximum Particles/m³ ≥0.5μm | Typical Applications in Stem Cell Research |

|---|---|---|---|

| A | ISO 5 | 3,520 [33] | Aseptic filling, open vial operations, critical open processes |

| B | ISO 6-7 | 35,200-352,000 [33] | Background environment for Grade A operations, cell processing |

| C | ISO 7 | 352,000 [33] | Component preparation, buffer and media preparation |

| D | ISO 8 | 3,520,000 [33] | Support areas, washing and staging areas, gowning rooms |

Pressure Cascade and Airflow Control

A fundamental principle in cGMP cleanroom design is the establishment of pressure differentials that create a directional airflow from cleaner to less clean areas, preventing the ingress of contaminants.

- Pressure Differential Model: Cleaner zones maintain higher pressure than adjacent less-clean areas, with typical differentials of 10–15 Pa between adjacent rooms [34]. This pressure cascade ensures air flows from critical processing areas toward support spaces, carrying potential contaminants away from product exposure sites.

- Airflow Patterns: Unidirectional airflow (UDAF), formerly known as laminar airflow, provides a consistent, parallel stream of HEPA-filtered air across critical zones, sweeping contaminants away from the product and processing area [34]. Non-unidirectional (turbulent) airflow is acceptable in less critical areas where product is not directly exposed.

- Air Change Rates: Proper air change rates are essential for maintaining cleanliness classifications, with higher grades requiring more frequent air changes. Grade A/B areas typically require significantly higher air change rates than Grade C/D areas, though specific rates should be determined through risk assessment and validation studies [34].

Table 2: Pressure Differential and Airflow Requirements

| Parameter | Grade A | Grade B | Grade C | Grade D |

|---|---|---|---|---|

| Min. Pressure Differential | 10-15 Pa relative to background [34] | 10-15 Pa relative to adjacent less clean areas [34] | 10-15 Pa relative to adjacent less clean areas [34] | Positive pressure relative to corridor [34] |

| Airflow Pattern | Unidirectional [34] | Non-unidirectional or mixed [34] | Non-unidirectional [34] | Non-unidirectional [34] |

| Air Change Rate (typical) | N/A (LAF device) | Significantly higher than lower grades [34] | Moderate [34] | Lower [34] |

Material and Personnel Flow

Controlling the movement of people, materials, and equipment is essential for maintaining cleanroom integrity and preventing cross-contamination.

- Unidirectional Flow: cGMP cleanrooms must adhere to unidirectional flow principles, where people, raw materials, and equipment move sequentially from "less clean" to "more clean" zones [34]. There should be no crossover or backtracking that could compromise cleaner areas.

- Segregated Pathways: Separate entry airlocks for people and materials enhance contamination control [34]. Dedicated gowning rooms should include step-over benches to facilitate proper attire donning while minimizing particle transfer [34].

- Process Flow Design: The facility layout should logically sequence operations from material receipt through to final product packaging, minimizing the need for intermediate material storage or backtracking. High-risk processes should be geographically separated from potentially contaminating activities [34].

Facility Design Specifications

Architectural Finishes and Materials

cGMP regulations mandate specific material requirements for cleanroom surfaces to enable effective cleaning and disinfection while minimizing particle generation.

- Wall Systems: Surfaces must be smooth, waterproof, easy-to-clean, and rigid to minimize contamination risk [36]. Preferred materials include fiber-reinforced plastic (FRP), uPVC, and high-quality stainless steel, all of which offer chemical resistance to harsh disinfectants [32].

- Flooring: Heat-welded vinyl with integral coved bases is standard, providing a seamless, smooth surface that prevents microbial buildup [32]. Static-dissipative options are available for environments where electrostatic discharge could damage sensitive equipment or affect processes [37].

- Ceilings: Cleanroom-rated ceiling systems should feature coved junctions with walls and flush-mounted lighting to eliminate corners where dust could collect [32]. The entire assembly must be airtight and compatible with regular decontamination procedures.

- Door Design: Doors must be seamless, easily cleanable, and resistant to cleaning agents [36]. Sliding doors are discouraged due to their inherent gaps and recesses that challenge effective cleaning [36]. Interlocking door systems prevent the simultaneous opening of adjacent spaces, maintaining pressure differentials [32].

Table 3: Surface Material Requirements for cGMP Cleanrooms

| Surface Type | Material Options | Key Properties | Maintenance Considerations |

|---|---|---|---|

| Walls | FRP, uPVC, Powder-coated steel, Stainless steel [32] | Smooth, non-shedding, chemical resistant [32] | Compatible with sporicidal agents, resistant to abrasion |

| Floors | Heat-welded vinyl, Static-dissipative vinyl, Epoxy [32] | Seamless, covable, chemical resistant [32] | Withstand frequent cleaning, non-slip surface |

| Ceilings | Cleanroom-rated grid systems with gasketed panels | Flush-mounted, airtight, cove corners [32] | Integrated lighting, accessible for maintenance |

| Doors | Interlocking, seamless [37] | Easy to clean, no recesses [36] | Interlock systems to maintain pressure [32] |

HVAC and Filtration Systems

The heating, ventilation, and air conditioning (HVAC) system forms the engineering core of any cGMP cleanroom, responsible for maintaining all critical environmental parameters.

- Air Filtration: HEPA filters are standard for cGMP cleanrooms, providing 99.97% efficiency in removing particles ≥0.3 micrometers [38]. For the most critical applications, ultra-low particulate air (ULPA) filters may be employed for even higher efficiency. Filter integrity testing is essential, with penetration not exceeding 0.03% [38].

- Air Handling Units: These systems must deliver filtered air at precise temperatures, humidity levels, and velocities while maintaining specified pressure differentials [36]. Redundant systems or backup power supplies are often necessary for critical environments to ensure uninterrupted operation.

- Monitoring and Control: Automated building management systems continuously monitor and log environmental parameters including temperature, humidity, and pressure differentials [32]. These systems typically incorporate audible and visual alarms to promptly alert staff to deviations from established parameters.

Monitoring and Control Systems

Comprehensive monitoring provides the data necessary to demonstrate continuous compliance with cGMP standards.

- Particle Monitoring: Continuous particle counting is required in Grade B and Grade A environments [37]. Laser particle counters measure both viable and non-viable particulates at specified locations and frequencies, with data logged for regulatory review.

- Environmental Parameters: Temperature and humidity must be continuously monitored and maintained within validated ranges appropriate for the specific stem cell processes being conducted [36].

- Microbial Monitoring: Active air sampling and surface monitoring detect viable organisms, with settle plates used to assess airborne microbial contamination over time [36]. Personnel monitoring through contact plates assesses gowning effectiveness.

Cleanroom Qualification Protocol

The qualification of cGMP cleanrooms follows a rigorous lifecycle approach encompassing multiple stages of verification and validation. This systematic process ensures the facility consistently operates according to design specifications and regulatory requirements.

Qualification Stages

User Requirements Specification (URS): This foundational document analyzes the need for the cleanroom and justifies its implementation, identifying contamination risks to products, processes, and people [36]. The URS includes statutory requirements, business considerations, and anticipated future needs.

Design Qualification (DQ): Verifies that the proposed cleanroom design is fit for its intended purpose through conceptual, basic, and detailed design stages [36]. DQ bridges the URS and construction phases, ensuring the design will meet all specified requirements before procurement and building commence.

Factory Acceptance Testing (FAT)/Site Acceptance Testing (SAT): FAT ensures equipment meets specifications before shipment, while SAT confirms installation complies with the design and operates as expected [36]. These tests verify installation completeness and performance parameters, including classification testing in accordance with ISO 14644-1 [36].

Installation Qualification (IQ): Documents that the cleanroom has been built and installed according to approved specifications and drawings [36]. IQ includes verification of as-built conditions, HVAC calibration, HEPA filter integrity test data review, critical equipment calibration status, and initial microbial contamination measurements [36].

Operational Qualification (OQ): Demonstrates that the fully functional cleanroom operates within specified parameters under "at-rest" conditions [36]. OQ testing includes:

- Airflow velocity and volume measurements

- Air pressure difference tests

- Filter integrity testing (DOP testing)

- Airflow visualization studies (smoke tests)

- Recovery testing

- Temperature and humidity uniformity mapping

- Lighting level verification

- Noise and vibration level checks

Performance Qualification (PQ): Confirms that the cleanroom consistently maintains required operational performance under "in-operation" conditions with typical personnel presence and manufacturing processes [36]. PQ involves:

- Cleanroom classification at in-operation state

- Determination of microbial contamination levels during simulated operations

- Verification of clean-up times and recovery rates

- Testing of worst-case operational scenarios

- Demonstration of operational robustness over a sustained period

Experimental Protocol: Cleanroom Recovery Test

Purpose: To determine the time required for a cleanroom to recover from a simulated particle generation event and return to its specified cleanliness classification.

Principle: Introducing an artificial aerosol challenge to the cleanroom and measuring the time required for particle counts to reduce to specified limits after the aerosol generation ceases.

Materials:

- Aerosol generator (capable of producing polydisperse particles)

- Laser particle counter(s) with data logging capability

- Environmental monitoring system

- Stopwatch or automated timer

Procedure:

- Ensure cleanroom is operational under standard conditions with HVAC system functioning normally.

- Place particle counter in location representative of critical zones.

- Generate aerosol challenge until particle counts exceed classification limit by at least 10-fold.

- Simultaneously cease aerosol generation and start timing.

- Record particle counts at predetermined intervals (e.g., every 30 seconds).

- Continue monitoring until particle counts have returned to the baseline levels specified for the cleanroom classification.

- Repeat test in multiple locations for comprehensive assessment.

Acceptance Criteria: The cleanroom must recover to specified cleanliness levels within the validated time frame, typically demonstrating a 100:1 reduction in particle counts within several minutes for higher classification areas.

Stem Cell Research Application

Facility Adaptation for Stem Cell Processing

Stem cell research and manufacturing present unique challenges that require specific adaptations to standard cGMP cleanroom designs.

- Closed System Processing: Whenever possible, stem cell processing should employ closed systems that minimize product exposure to the immediate environment. When processing occurs in closed systems with aseptic validation, it may be performed in ISO-7 (Class 10,000) environments rather than the more stringent ISO-5 (Class 100) required for open manipulations [33].

- Incubation Facilities: Cell culture incubators represent potential contamination sources and should be located in Grade C environments at minimum. Their placement must allow for adequate airflow around the equipment while maintaining accessibility for monitoring and maintenance.

- Cryopreservation Areas: Facilities must include appropriate space for controlled-rate freezing and secure storage of cryopreserved cell products. Liquid nitrogen storage presents asphyxiation risks that must be addressed through proper room ventilation and oxygen monitoring.

- Material Flow for Cell Culture: The pathway for media, supplements, and culture vessels must maintain sterility from preparation through to final use. Dedicated pass-through autoclaves and vaporized hydrogen peroxide (VHP) chambers can facilitate material transfer between classified areas.

Case Study: GMP-Grade Neural Progenitor Cell Derivation

The implementation of a GMP-compliant protocol for deriving long-term neuroepithelial stem cell progenitors (lt-NES) from clinical-grade human embryonic stem cells demonstrates the practical application of cGMP cleanroom principles [28].

Process Overview:

- Undifferentiated hESCs are dissociated into single cells using StemPro Accutase in a Grade B background environment with Grade A biological safety cabinet.

- Cells are suspended in GMP Essential 6 medium and transferred to Aggrewell plates for embryoid body formation.

- After 5 days, embryoid bodies are plated onto GMP-grade recombinant Laminin 521-coated vessels in Grade C environment.

- Neural induction proceeds for 3-5 days with daily media changes using GMP N2 media formulations.

- Neural rosettes are selected using STEMdiff Neural Rosette Selection Reagent.

- Selected rosettes are expanded in N2 media supplemented with GMP-grade FGF and EGF to establish lt-NES cultures.

Critical Facility Considerations:

- All reagents must be GMP-grade, including recombinant enzymes, growth factors, and matrix components [28].

- Cell processing between open and closed systems determines the required cleanroom classification for each step [33].

- Environmental monitoring must demonstrate consistent control throughout the extended culture period, which may span several weeks.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 4: GMP-Grade Reagents for Clinical-Grade Stem Cell Research

| Reagent Category | Specific Examples | Function | GMP-Grade Source Examples |

|---|---|---|---|

| Basal Media | Essential 8, Essential 6, X-VIVO-15 [28] | Support growth and maintenance of stem cells | Thermo Fisher Scientific CTS [28] |

| Growth Factors | FGF, EGF, SCF, TPO, Flt3-L [35] [28] | Direct stem cell proliferation and differentiation | Bio-Techne GMP-grade [28] |

| Dissociation Agents | StemPro Accutase, GMP EDTA [28] | Cell passaging and single-cell suspension | Thermo Fisher Scientific GMP-grade [28] |

| Extracellular Matrices | Recombinant Laminin 521, Vitronectin [28] | Provide substrate for cell attachment and signaling | Biolamina, Thermo Fisher Scientific CTS [28] |

| Supplements | N2, B27, Revitacell [28] | Enhance cell survival and differentiation | Thermo Fisher Scientific CTS [28] |

| Cell Culture Supplements | LentiBOOST, protamine sulfate [35] | Enhance transduction efficiency in gene therapy | Commercial GMP-grade sources [35] |

The design and implementation of cGMP-compliant cleanrooms for clinical-grade stem cell research requires meticulous attention to architectural finishes, HVAC systems, monitoring capabilities, and qualification protocols. By adhering to the principles and practices outlined in this application note, researchers and manufacturers can create controlled environments that protect the integrity of stem cell products throughout their manufacturing lifecycle. The facility itself becomes an essential tool in ensuring the safety, purity, and efficacy of advanced stem cell therapies, ultimately supporting their successful translation from research concepts to clinically impactful treatments for patients.

From Donor to Dose: A Step-by-Step GMP Manufacturing Workflow

Within the framework of Good Manufacturing Practice (GMP) for clinical-grade stem cells, the initial steps of donor selection and tissue acquisition are critical. These foundational processes determine the safety, quality, and ultimate efficacy of the final cell-based medicinal product. This document outlines standardized, ethically grounded protocols for the sourcing and collection of starting materials, specifically addressing mesenchymal stem cells (MSCs) from the infrapatellar fat pad and hematopoietic stem cells (HSCs) for allogeneic transplantation and gene therapy. Adherence to these protocols ensures compliance with regulatory standards and lays the groundwork for successful translational research [39] [7].

Ethical Donor Selection

Ethical donor selection balances the clinical needs of the recipient with the safety and autonomy of the donor, with particular care required when the donor is a minor.

Clinical and Ethical Considerations for Allogeneic HSC Donors

For allogeneic Hematopoietic Stem Cell Transplantation (allo-HSCT), stem cells may be obtained from mobilized peripheral blood, bone marrow, or umbilical cord blood [40]. The selection process must prioritize the safety of both donor and recipient.

Key Ethical Principles:

- Informed Consent: Donors must receive accurate information regarding potential adverse events and the health burden of donation [40] [41].

- Risk-Benefit Analysis: Donation should be excluded when excessive risks to the donor are foreseeable, and the recipient's risks must be outweighed by the expected benefits [40].

- Management of Conflict of Interest: A distinct living donor advocacy team is recommended, especially for minor donors, to ensure the decision is free of coercion and that the donor's interests are protected [41]. This is crucial as parental authority in such cases involves a natural conflict of interest between the well-being of the sick child and the healthy donor child [41].

Donor Eligibility Determination: This is based on review of medical records, a physical exam, and clinical laboratory testing for Relevant Communicable Disease Agents and Diseases (RCDADs). Required tests typically include screening for HIV, Hepatitis B & C, HTLV, Treponema pallidum, and others as per regulations (FDA 21 CFR 1271) [7].

Sourcing of MSC Donor Tissue

MSCs can be isolated from various tissues, with the infrapatellar fat pad (IFP) representing a less invasive source compared to bone marrow. IFP tissue is often available as surgical waste from procedures like anterior cruciate ligament (ACL) reconstruction, reducing patient morbidity [39] [6].

Protocol Approvals and Informed Consent:

- The collection protocol must be approved by an institutional research ethics review committee [39] [6].

- Written informed consent must be obtained from patients after screening against defined inclusion and exclusion criteria [39] [6].

Table 1: Example Donor Demographics for Infrapatellar Fat Pad Sourcing

| Sample ID | Age | Sex | Body Mass Index |

|---|---|---|---|

| FPMSC-8 | 22 | M | 26.0 |

| FPMSC-11 | 24 | M | 20.5 |

| FPMSC-13 | 20 | F | 38.3 |

Source: Adapted from [6]

Tissue Acquisition and Initial Processing Workflows

The acquisition process varies by tissue source but must consistently adhere to aseptic techniques and Good Tissue Practices (GTP).

Umbilical Cord Blood for iPSC Generation

Cord blood is a common starting material for generating clinical-grade induced pluripotent stem cell (iPSC) banks [7]. The acquisition workflow involves multiple critical checkpoints to ensure GMP compliance.

Key Steps:

- Informed Consent: Must cover the intended use of donated tissue, benefits, risks, confidentiality, and voluntary participation, and must be approved by an Institutional Review Board (IRB) [7].

- Tissue Recovery: Performed by trained specialists in a hospital setting using aseptic techniques compliant with GTP [7].

- Shipping and Receiving: The cord blood unit is packaged and shipped to the manufacturing facility using validated procedures. Upon receipt, the tissue is stored appropriately and transferred to a designated cell therapy area [7].

- Quarantine and Release: The initial manufacturing steps are performed under quarantine until donor screening and testing results are received, reviewed by a qualified person (e.g., a medical director) and the Quality Assurance (QA) group, and the tissue is formally released [7].

Infrapatellar Fat Pad (IFP) Processing for MSC Isolation

The protocol for isolating MSCs from IFP tissue involves mechanical and enzymatic processing to derive a primary cell population.

- Tissue Harvesting: IFP tissue (10-20 g) is acquired using an arthroscopic shaver and sterile collection chamber during ACL reconstructive surgery.

- Mechanical Processing: The tissue is cut into approximately 1 mm³ pieces.

- Enzymatic Digestion: The minced tissue is digested with 0.1% collagenase in serum-free media for 2 hours at 37°C.

- Cell Separation: The digested tissue is centrifuged at 300 ×g for 10 minutes. The supernatant is removed, and the cell pellet is washed with PBS and filtered through a 100 μm filter.

- Primary Culture: The filtered cells are centrifuged again, and the resulting pellet is resuspended in standard MSC media (e.g., MEM α supplemented with 10% FBS and gentamicin) for initial culture.

- Cryopreservation: Cells are typically cryopreserved at the end of the first passage using a cryoprotectant like DMSO.

Experimental Protocols for GMP-Compliant Cell Expansion and Characterization

GMP-Compliant Expansion of MSCs

Transitioning from research-grade to clinical-grade MSCs requires the use of defined, animal component-free media to eliminate risks of contamination and immunogenicity [39] [6].

Subculture Protocol:

- Thawing: Cryopreserved FPMSCs are thawed and seeded in standard or animal component-free media.

- Passaging: Cells are passaged at 80-90% confluency and seeded at a density of 5 × 10³ cells/cm².

- Media Comparison: The performance of different GMP-compliant media (e.g., MesenCult-ACF Plus Medium vs. MSC-Brew GMP Medium) should be evaluated against standard MSC media [39] [6].

Quantitative Assessment of Cell Proliferation and Potency:

- Cell Doubling Time: Calculated over multiple passages using the formula:

Doubling Time = (duration * ln(2)) / ln(final concentration / initial concentration)[39] [6]. Cells are counted at each passage using a hemacytometer. - Colony Forming Unit (CFU) Assay: To assess clonogenic potential (potency). Cells are seeded at low densities (e.g., 20, 50, 100, and 500 cells per dish) and grown for 10 days. Colonies are then fixed with formalin, stained with Crystal Violet, and imaged for counting [39] [6].

Table 2: Quantitative Results from GMP Media Comparison on FPMSCs

| Assessment Metric | Standard MSC Media | MesenCult-ACF Plus | MSC-Brew GMP Medium |

|---|---|---|---|

| Doubling Time | Higher | Intermediate | Lower (indicating enhanced proliferation) |

| Colony Formation | Standard | Intermediate | Higher (indicating enhanced potency) |

| Post-Thaw Viability | >70% (minimum requirement) | >95% | >95% (maintained for up to 180 days) |

| Sterility | Compliant | Compliant | Compliant |

| Marker Expression | Maintained | Maintained | Maintained |

Source: Summarized from [39] [6]

Quality Control and Release Criteria

A comprehensive QC strategy is essential for product release. The following assays were validated for GMP-FPMSCs derived from multiple donors [39] [6]:

- Viability: Assessed using Trypan Blue exclusion, with results >95% (>70% required for release).

- Sterility: Tested using the Bact/Alert system.

- Purity and Identity: