Optimizing Cryopreservation and Thawing for Personalized Stem Cell Products: A Guide for Maximizing Viability and Therapeutic Potential

This article provides a comprehensive guide for researchers and drug development professionals on optimizing cryopreservation and thawing processes for personalized stem cell therapies.

Optimizing Cryopreservation and Thawing for Personalized Stem Cell Products: A Guide for Maximizing Viability and Therapeutic Potential

Abstract

This article provides a comprehensive guide for researchers and drug development professionals on optimizing cryopreservation and thawing processes for personalized stem cell therapies. Covering foundational principles, current methodological applications, and advanced troubleshooting, it synthesizes the latest research and survey data to address key challenges in post-thaw cell recovery, viability, and functional integrity. By presenting evidence-based strategies and comparative analyses of different processing methods, this resource aims to support the development of robust, standardized protocols that ensure the consistent quality and efficacy of stem cell-based therapeutics, from research to clinical application.

The Science of Stem Cell Cryopreservation: Preserving Cellular Potential

Frequently Asked Questions (FAQs)

1. What is the fundamental principle behind cryopreservation? Cryopreservation works by cooling biological materials to extremely low temperatures (typically between -80°C and -196°C) to dramatically reduce all biochemical and metabolic activity, effectively placing cells in a state of suspended animation. This process halts biological decay and preserves cell viability and functionality for future use [1] [2].

2. Why is the cooling rate so critical, and what is the ideal rate? The cooling rate is vital because cooling too quickly leads to lethal intracellular ice crystal formation, while cooling too slowly causes excessive cell dehydration and solute imbalance. A controlled rate of approximately -1°C per minute is ideal for freezing many cell types, as it allows water to safely exit the cell before freezing [2] [3].

3. What are cryoprotective agents (CPAs) and how do they work? CPAs are chemicals that protect biological materials from freezing damage. They function primarily by preventing the formation of damaging ice crystals inside cells. Common examples include Dimethyl Sulfoxide (DMSO) and glycerol. They are categorized as:

- Intracellular CPAs: Small molecules that penetrate the cell membrane (e.g., DMSO, glycerol).

- Extracellular CPAs: Large molecules that do not penetrate the cell (e.g., sucrose, dextrose) [1] [3].

4. What is the difference between controlled-rate freezing and passive freezing? The choice between these methods involves a trade-off between control and simplicity, which is crucial for process development in personalized medicine.

Table: Comparison of Freezing Methods

| Feature | Controlled-Rate Freezing | Passive Freezing |

|---|---|---|

| Process Control | High control over critical cooling parameters [4] | Low control; relies on passive heat transfer [4] |

| Consistency | High, ideal for reproducible manufacturing [4] | Lower, potential vial-to-vial variability [4] |

| Cost & Complexity | High; requires specialized equipment and expertise [4] | Low-cost and simple operation [4] |

| Best Application | Late-stage clinical & commercial products; sensitive cells [4] | Early R&D and early-stage clinical development [4] |

5. What are the key challenges in cryopreserving cells for therapy? Major challenges include:

- Scaling: The "ability to process at a large scale" was identified as the biggest hurdle by 22% of industry survey respondents [4].

- Cryoprotectant Toxicity: Reducing the concentration of potentially toxic agents like DMSO in final therapeutic formulations [5].

- Post-Thaw Viability: Ensuring high cell recovery, viability, and maintained functionality after thawing [4] [3].

Troubleshooting Guides

Poor Post-Thaw Viability

Problem: Cells show low viability or poor recovery after thawing.

Possible Causes and Solutions:

Cause 1: Poor Pre-Freeze Cell Health

Cause 2: Suboptimal Freezing Rate

Cause 3: Inadequate Thawing Technique

Cause 4: Incorrect Cell Concentration

- Solution: Freeze cells at an optimal concentration. A very high concentration can lead to clumping, while a very low concentration can result in low viability. A typical range is 1x10^3 to 1x10^6 cells/mL; determine the ideal concentration for your specific cell type [2].

Low Efficiency in iPSC Colony Formation Post-Thaw

Problem: Thawed induced Pluripotent Stem Cells (iPSCs) fail to form colonies or show poor attachment.

Specific Troubleshooting Steps:

- Check Cell Condition Pre-Freeze: Feed iPSCs daily before cryopreservation and freeze them 2-4 days after passaging. Ensure cell clumps are properly dissolved to allow cryoprotectant penetration [3].

- Validate Cryopreservation Protocol: Handle cells gently during harvesting (centrifuge at 200-300 x g for 2 minutes) and use fresh freezing media. The recommended freezing density for iPSCs is typically 1-2 x 10^6 cells/mL [3].

- Optimize Thawing and Seeding: After rapid thawing, transfer the cell suspension drop-by-drop into 10 volumes of warm medium to gently dilute the cryoprotectant. Seed cells at a high density (e.g., 2x10^5 - 1x10^6 viable cells per well of a 6-well plate) onto Matrigel-coated plates [3].

Contamination and Genetic Instability

Problem: Cultures show contamination or exhibit genetic drift over time.

Preventative Best Practices:

- Aseptic Technique: Use proper sterile techniques and wipe all containers with 70% ethanol or isopropanol before opening [2].

- Rigorous Testing: Test cells for mycoplasma and other microbial contamination before freezing [2].

- Detailed Record Keeping: Maintain accurate records of passage numbers, lot numbers for all reagents, and freezing protocols. This ensures traceability and helps identify the source of any problems [6].

- Proper Long-Term Storage: For long-term storage, use liquid nitrogen tanks in the vapor phase (-135°C to -196°C). Storage at -80°C is acceptable for less than a month but leads to declining viability over time [2] [7].

The Scientist's Toolkit: Essential Reagents and Materials

Table: Key Reagents for Cryopreservation Workflows

| Item | Function & Application | Example Use Case |

|---|---|---|

| DMSO | An intracellular cryoprotectant that penetrates the cell to prevent ice crystal formation. | Standard cryopreservation of many cell lines at a final concentration of ~10% [1] [3]. |

| Serum-Free Freezing Media | A chemically-defined, ready-to-use solution providing a safe, protective environment; often GMP-manufactured. | Critical for cell and gene therapy products (e.g., CryoStor CS10) [2]. |

| Specialized Cell Media | Formulated for specific, sensitive cell types to maximize post-thaw recovery and functionality. | mFreSR for human ES/iPS cells; STEMdiff media for cardiomyocytes [2]. |

| Controlled-Rate Freezer | Equipment that precisely controls the cooling rate, typically at -1°C/min, for optimal viability. | Essential for freezing cell therapy products like CAR-T cells or iPSCs [4] [7]. |

| Cryogenic Vials | Single-use, sterile vials designed for ultra-low temperature storage. | Use internally-threaded vials to minimize contamination risk during storage [2] [3]. |

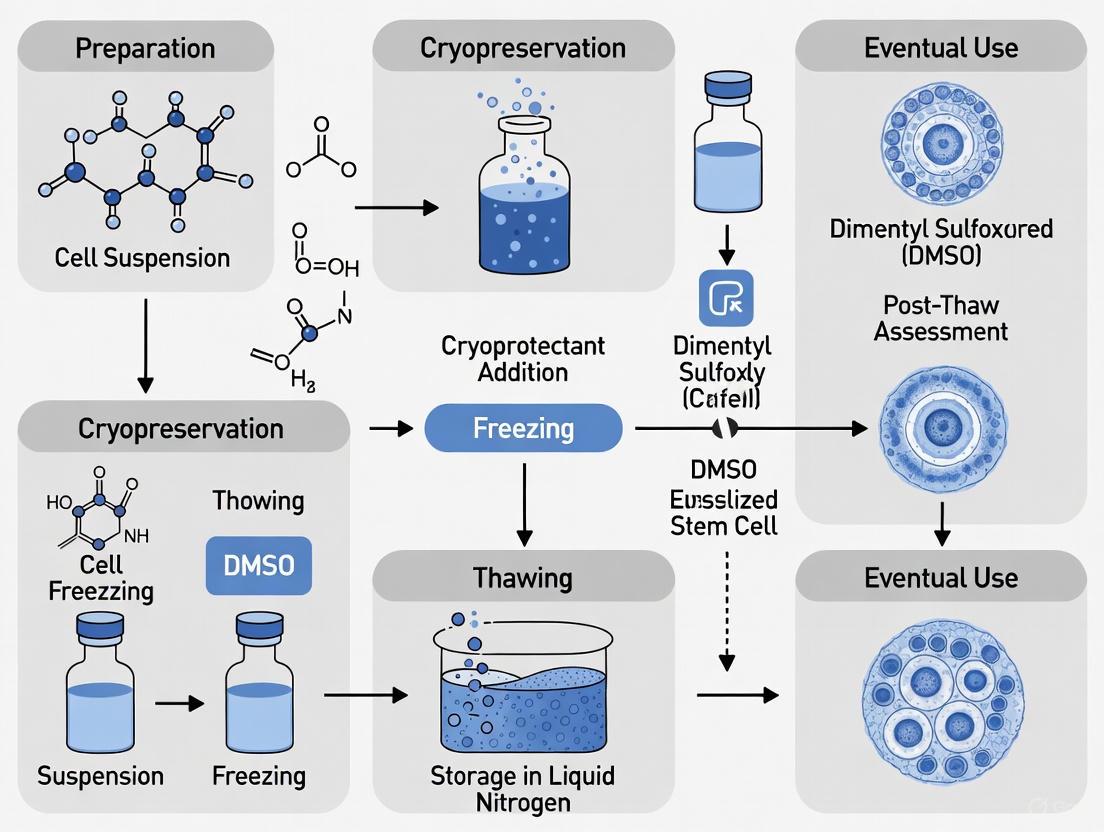

Experimental Workflow and Protocol

The following diagram illustrates the core cryopreservation workflow, highlighting the critical parameters at each stage that ensure biochemical activity is successfully halted while maintaining cell viability.

Detailed Step-by-Step Protocol for Freezing Cells

Harvesting:

- Culture cells to their maximum growth phase, typically >80% confluency and in the log phase of growth [2] [6].

- Detach cells using standard methods (e.g., trypsin) and collect them in a centrifuge tube.

- Centrifuge to pellet the cells (e.g., 200-300 x g for iPSCs). Carefully remove the supernatant [2] [3].

Preparation of Freezing Medium:

- Resuspend the cell pellet in an appropriate, cold freezing medium.

- For many standard cell types, a medium containing 10% DMSO in FBS is used. For sensitive or therapeutic cells, use a specialized, commercially available, serum-free medium like CryoStor CS10 [2] [3].

- Keep the mixture cold to minimize CPA toxicity.

Aliquoting and Cooling:

- Quickly aliquot the cell suspension into labeled cryogenic vials.

- Place the vials immediately into a controlled-rate freezing container (e.g., CoolCell) and transfer it to a -80°C freezer. Alternatively, use a programmable controlled-rate freezer [2] [3].

- Leave the vials in the -80°C freezer for a minimum of 2-4 hours, or preferably overnight.

Long-Term Storage:

Troubleshooting Guides

Low Post-Thaw Viability

Problem: Cell viability is unacceptably low immediately after thawing.

| Potential Cause | Diagnostic Steps | Corrective Action |

|---|---|---|

| Intracellular Ice Crystal Formation [8] [9] | Check cooling rate documentation; review freeze curves if available. [4] | Implement controlled-rate freezing at -1°C/min to -3°C/min. [9] Validate the freezing profile for your specific cell type. [4] |

| Osmotic Stress & Cryoprotectant Toxicity [4] [8] | Audit cryoprotectant composition (DMSO concentration, additives) and equilibration time. [10] | Optimize DMSO concentration (test between 5-10%); [10] use serum-free, chemically defined cryomedium; [11] ensure gradual addition and removal of cryoprotectant. |

| Suboptimal Thawing Process [4] [9] | Observe thawing technique; check water bath temperature consistency. | Adopt a rapid thawing protocol (e.g., 37°C water bath until just ice-free). [9] Standardize the thawing process across all staff. [4] |

| Extended Storage Duration [12] | Review inventory records for storage time. | Note that viability can decline ~1.02% per 100 days at -80°C. [12] Prioritize use of older batches and ensure storage at ≤ -150°C or in liquid nitrogen vapor phase for long-term stability. [10] [9] |

Poor Functional Integrity Post-Thaw

Problem: Cells are viable but show impaired therapeutic function (e.g., differentiation, immunomodulation).

| Potential Cause | Diagnostic Steps | Corrective Action |

|---|---|---|

| Cryo-Induced Apoptosis [13] | Perform a Live/Apoptosis-Negative (LAN) assay post-thaw, not just viability staining. [13] | Include caspase inhibitors in recovery media; allow a 24-hour recovery period post-thaw before functional assays. [8] |

| Inadequate Post-Thaw Processing [13] | Analyze recovery and purity metrics for different isolation methods (e.g., Wash-only vs. Bead depletion). | Select a post-thaw processing method that aligns with the functional goal (e.g., bead depletion for high purity and long-term function). [13] |

| Damage to Critical Cell Subpopulations | Use flow cytometry to characterize immune subset recovery (e.g., T-cells, CD14+ cells) before and after culture. [13] | Modify the cryopreservation formula; avoid methods that aggressively deplete critical subsets like CD14+ cells if they are required for function. [13] |

| Inconsistent Freezing Profiles [4] | Analyze freeze curves for deviations; correlate with post-thaw functional data. | Move away from "default" controlled-rate freezer (CRF) profiles. [4] Develop and validate an optimized freezing protocol for your specific cell product (e.g., T-cells, iPSCs). [4] |

Frequently Asked Questions (FAQs)

Q1: What is the most reliable method for assessing post-thaw viability, and why is there sometimes a discrepancy between viability and actual function?

A1: The choice of viability assay significantly impacts results. The acridine orange (AO) staining method has been shown to demonstrate greater sensitivity to delayed cellular damage compared to some other methods like 7-AAD [12]. Viability and function can decouple because cryopreservation can induce early-stage apoptosis, where cells still exclude dyes but are destined for cell death and are functionally compromised [13]. For a more predictive assessment, incorporate a Live/Apoptosis-Negative (LAN) assay or a functional assay like a Colony-Forming Unit (CFU) test alongside simple viability staining [13].

Q2: Our lab uses uncontrolled-rate freezing in a -80°C freezer. Is this sufficient for clinically-oriented research?

A2: Evidence suggests that long-term storage at -80°C can maintain sufficient CD34+ hematopoietic stem cell viability for successful engraftment, albeit with a gradual, time-dependent decline in viability (~1.02% per 100 days) [12]. However, the field is moving towards controlled-rate freezing (CRF), with 87% of survey respondents in the cell and gene therapy industry using CRF for its superior control over critical process parameters [4]. CRF reduces variability, improves consistency, and is strongly recommended for late-stage clinical development and commercialization [4].

Q3: We observe good cell recovery after thawing, but the cells perform poorly in subsequent experiments. What could be happening?

A3: This is a classic sign of compromised functional integrity. Key factors include:

- Post-Thaw Processing: The method used to process cells after thawing involves critical trade-offs. A simple "wash-only" method may yield high cell numbers but low purity, while bead-based depletion can provide high purity and better preserve long-term function [13].

- Cryoprotectant Toxicity: Extended exposure to DMSO post-thaw is toxic [4] [8]. Ensure rapid and gentle dilution and removal of cryoprotectant immediately upon thawing.

- Lack of Recovery Time: Thawed cells are under metabolic stress. Allowing an overnight recovery period in culture before using them in assays can significantly improve functional outcomes [8].

Q4: What are the key considerations for scaling up our cryopreservation process from research to clinical-grade manufacturing?

A4: Scaling is identified as a major hurdle [4]. Key considerations include:

- Process Consistency: When cryopreserving an entire manufacturing batch, the time between the start and end of freezing can introduce variability. Staggering sub-batches adds risk of process irreproducibility [4].

- Quality Control: Move beyond post-thaw analytics alone. Incorporate process data, such as freeze curves, as part of manufacturing controls to identify deviations in Controlled-Rate Freezer (CRF) performance [4].

- Automation & Innovation: To enhance scalability and consistency, the industry is integrating automation, AI-driven predictive modeling for freezing protocols, and novel technologies like ice-free vitrification and nanoparticle-based cryoprotectants [11] [8].

Table 1: Impact of Storage Conditions on Cell Viability

| Cell Type | Storage Condition | Storage Duration | Post-Thaw Viability | Key Finding | Source |

|---|---|---|---|---|---|

| CD34+ HSC Products | -80°C (uncontrolled-rate) | Median 868 days | 94.8% (median) | Viability decline of ~1.02% per 100 days; sufficient for engraftment. | [12] |

| Cord Blood Mononuclear Cells (CBMCs) | Not Specified (Likely ≤ -150°C) | N/A | Varies by method | Post-thaw processing method critically impacts recovery & function, not just viability. | [13] |

| Mesenchymal Stem Cells (MSCs) | Liquid Nitrogen (with CS-SC-D1 medium) | N/A | >90% | Clinical-grade, GMP cryomedium can consistently maintain high viability. | [14] |

Table 2: Comparison of Post-Thaw Processing Methods for Cord Blood

| Processing Method | Purity (Depletion Efficiency) | CBMC Yield/Recovery | Impact on Functional Fitness | [13] |

|---|---|---|---|---|

| Wash-Only | Lowest | Highest | Retains all cell types, but may include debris. | [13] |

| Density Gradient | Moderate | Moderate | Standardized separation of mononuclear cells. | [13] |

| Bead Depletion (CD15/CD235a) | Highest | Lower | Best preserved cell viability over 5 days in culture. | [13] |

| EasySep PBMC Isolation Kit | High | Lower | Highest initial viable cells (Day 0); significantly depletes CD14+ cells, reducing T-cell proliferation. | [13] |

Experimental Protocol: Evaluating Post-Thaw Recovery & Function

This protocol outlines a comprehensive method to assess not only viability but also the functional integrity of thawed stem cell products, based on current research practices [13].

Objective: To systematically evaluate the impact of different post-thaw processing methods on cell recovery, viability, and functional fitness.

Materials:

- Cryopreserved cell product (e.g., Cord Blood Unit, PBSCs)

- Water bath or automated warmer (37°C)

- Pre-warmed complete culture medium

- Centrifuge

- Materials for post-thaw processing (e.g., wash buffers, density gradient media, depletion beads/kits)

- Flow cytometer with appropriate antibodies for viability (e.g., 7-AAD) and immunophenotyping

- Cell culture incubator (37°C, 5% CO₂)

- Reagents for functional assays (e.g., CFU assay kit, apoptosis/LAN assay kit, T-cell stimulation cocktail)

Procedure:

- Thawing: Rapidly thaw the cryovial/cryobag in a 37°C water bath until only a small ice crystal remains. Immediately proceed to the next step [9].

- Dilution & Primary Wash: Gently transfer the thawed contents to a tube containing a pre-warmed volume of culture medium (e.g., 10x volume). Mix gently. Centrifuge at a moderate speed (e.g., 300-400 x g) for 5-10 minutes. Carefully decant the supernatant [8].

- Post-Thaw Processing (Split into Groups): Resuspend the cell pellet and divide into aliquots for different processing methods as per your experimental design:

- Group A (Wash-Only): Resuspend in medium, centrifuge, and resuspend for counting.

- Group B (Density Gradient): Isolate mononuclear cells using a standard Ficoll or similar density gradient centrifugation protocol.

- Group C (Bead Depletion): Follow manufacturer's instructions for immunomagnetic bead-based depletion of unwanted cells (e.g., CD15/CD235a).

- Group D (PBMC Isolation Kit): Process cells using a direct isolation kit per manufacturer's guide.

- Day 0 Analysis:

- Cell Count & Viability: Perform a cell count and viability assessment for all groups using your preferred method (e.g., trypan blue, AO/Propidium Iodide, or flow cytometry with 7-AAD) [12].

- Immunophenotyping: Use flow cytometry to analyze the composition of immune cell subsets in each group (e.g., CD3+ T-cells, CD14+ monocytes, CD34+ HSCs) [13].

- Apoptosis Assay: Perform a Live/Apoptosis-Negative (LAN) assay on a portion of the cells from each group to quantify early apoptotic events [13].

- Functional Assessment (Culture):

- Culture a defined number of viable cells from each group under standard conditions for 5 days. Optionally, add T-cell activation stimuli to assess proliferation capacity.

- Day 5 Analysis:

- Re-assess cell count and viability.

- Perform a T-cell proliferation assay (e.g., CFSE dilution).

- Repeat the LAN assay to evaluate the stability of the culture.

- For HSCs, perform a Colony-Forming Unit (CFU) assay to assess clonogenic potential.

Workflow and Decision Diagrams

Diagram 1: Post-Thaw Viability Assessment Workflow

Diagram Title: Comprehensive Viability and Function Assessment Pathway

Diagram 2: Post-Thaw Processing Method Decision Tree

Diagram Title: Post-Thaw Processing Method Selection Guide

The Scientist's Toolkit: Essential Reagents & Materials

Table 3: Key Research Reagent Solutions for Cryopreservation Optimization

| Item | Function & Rationale | Example / Specification |

|---|---|---|

| Controlled-Rate Freezer (CRF) | Provides precise control over cooling rate, a critical process parameter (CPP) that minimizes intracellular ice formation and osmotic stress, ensuring batch-to-batch consistency. [4] | Industry standard for clinical-grade manufacturing; preferred over passive freezing. [4] |

| DMSO-based Cryomedium | The most common permeating cryoprotectant. Disrupts hydrogen bonding to prevent ice crystal formation and stabilizes cell membranes. [8] | Concentrations typically 5-15%; often combined with cell culture media, albumin, or other supplements. [10] |

| Serum-Free / Chemically Defined Media | Redishes variability and safety risks associated with animal serum. Supports regulatory compliance for clinical applications. [11] | Commercially available GMP-grade formulations (e.g., CS-SC-D1 for MSCs). [14] |

| Programmable Water Bath / Thawing Device | Ensures rapid, consistent, and controlled thawing at ~37°C, which is critical for high viability. Reduces contamination risk vs. traditional water baths. [4] [9] | Provides the recommended warming rate of ~45°C/min for many cell types. [4] |

| Immunomagnetic Bead Kits | For post-thaw cell processing to achieve high purity of specific cell populations (e.g., CD15/CD235a depletion from CBMCs), which can enhance functional outcomes. [13] | Kits like EasySep; selection depends on target cell population and required purity. [13] |

Impact of Cryopreservation on Critical Quality Attributes (CQAs)

Cryopreservation is an indispensable process in the development of personalized stem cell products, enabling vital pause points between manufacturing and final administration. However, this process introduces significant stresses that can directly compromise the Critical Quality Attributes (CQAs) essential for therapeutic efficacy and safety. CQAs are defined biological, chemical, or physical properties that must be controlled within appropriate limits to ensure product quality. For cell-based therapies, these typically include cell viability, identity, potency, and purity [4] [15].

The journey from a controlled-rate freezer to the patient involves multiple risks. During freezing and thawing, cells are subjected to physical and chemical stresses that can lead to osmotic damage, intracellular ice crystal formation, and prolonged exposure to cytotoxic cryoprotectants like dimethyl sulfoxide (DMSO) [4] [16] [15]. These insults can diminish cell viability and recovery, alter cell surface markers, and impair critical biological functions. Furthermore, the industry faces a major challenge in scaling cryopreservation processes without introducing variability that affects CQAs [4]. This technical support center provides targeted guidance to troubleshoot these challenges, ensuring that your cryopreserved stem cell products consistently meet the stringent CQA standards required for clinical application.

Troubleshooting Guides

FAQ 1: How does the choice between controlled-rate freezing and passive freezing impact my stem cell product's CQAs?

Answer: The freezing method directly influences the consistency of your process and the viability of your final product. Controlled-rate freezing (CRF) provides precise manipulation of cooling parameters, which is critical for managing ice crystal formation and minimizing osmotic stress—key factors affecting cell viability and potency [4] [2]. In contrast, passive freezing in a -80°C isopropanol chamber offers a low-cost, simple alternative but sacrifices control over critical process parameters, leading to greater variability in post-thaw CQAs [4] [2].

Industry surveys reveal that 87% of cell therapy developers use controlled-rate freezing, with its adoption being nearly universal for late-stage and commercial products [4]. The table below summarizes the core trade-offs:

Table: Impact of Freezing Method on Process and Product CQAs

| Feature | Controlled-Rate Freezing (CRF) | Passive Freezing |

|---|---|---|

| Control over Cooling Rate | Precise control (e.g., -1°C/min) [2] | Uncontrolled, variable rate |

| Impact on Viability | Maximized by avoiding intracellular ice [2] | Often lower and more variable |

| Process Consistency | High, suitable for cGMP and late-stage clinical products [4] | Low, common in early research [4] |

| Infrastructure Cost | High (specialized equipment, LN2) [4] | Low (freezing container, -80°C freezer) [4] |

| Scale-Up Bottleneck | Can be a bottleneck for large batches [4] | Simple to scale in terms of vial numbers [4] |

Recommendation: For programs advancing toward clinical trials, adopting controlled-rate freezing early is a best practice. Switching from passive to controlled-rate freezing later requires complex and costly process comparability studies [4].

FAQ 2: My post-thaw viability is low. What are the primary causes, and how can I address them?

Answer: Low post-thaw viability is a common symptom of cryo-injury, which manifests as three primary types of damage: osmotic damage, mechanical damage from ice crystals, and oxidative damage from reactive oxygen species (ROS) [15]. The root cause often lies in suboptimal protocols for freezing or, just as critically, thawing.

The diagram below illustrates the interconnected mechanisms of cryo-injury that lead to reduced viability and impaired CQAs.

Troubleshooting Steps:

- Audit Your Thawing Rate: A rapid thaw is non-negotiable. Quickly thaw cells by gently swirling the vial in a 37°C water bath until only a small ice crystal remains, then immediately dilute out the cryoprotectant. Slow thawing dramatically increases exposure to cytotoxic DMSO and allows damaging ice recrystallization [17] [2] [18].

- Verify Your Freezing Profile: For controlled-rate freezers, do not assume the "default" profile is optimal. While 60% of users employ default profiles, challenging cell types like iPSC-derived cardiomyocytes or neural progenitors often require optimized cooling rates to minimize chilling injury and intracellular ice formation [4].

- Investigate Cryoprotectant Toxicity: If you are required to use DMSO-free or low-DMSO media, be aware that standard slow-freeze protocols may perform poorly. This often necessitates dedicated process development to optimize freezing profiles for alternative cryoprotectant formulations [16].

- Implement Process Analytical Technology (PAT): Use freeze curve data from your controlled-rate freezer as a process control. Deviations from a qualified "golden batch" profile can predict low viability before you even run post-thaw analytics, allowing you to investigate the freezing system's performance [4].

FAQ 3: The CQAs of my thawed cells are inconsistent across vials from the same batch. How can I improve uniformity?

Answer: Inconsistency in CQAs, such as variable viability or potency, between vials of the same batch points to issues in process robustness and a lack of well-qualified equipment.

Key Investigation Areas and Solutions:

- Qualify Your Controlled-Rate Freezer (CRF): A leading cause of variability is an unqualified freezing process. Nearly 30% of labs rely solely on vendor qualification, which may not represent your specific use case [4].

- Action: Perform a full temperature mapping study of your CRF chamber. This should evaluate a range of conditions, including full vs. empty loads, different vial locations, and various container types and fill volumes. This ensures all vials experience the same thermal environment [4].

- Standardize the Thawing Process: Manual thawing in a water bath is a significant source of variability. It introduces contamination risk and relies on operator technique to judge the endpoint [4].

- Control Pre-Freeze Cell State: Inconsistency can originate from the starting material.

- Action: Ensure cells are harvested during their maximum growth phase (log phase) with >80% confluency and are free of microbial contamination [2]. Standardize the cell concentration and volume per vial to ensure uniform heat transfer during freezing and thawing.

The Scientist's Toolkit: Essential Reagents and Materials

Optimizing your cryopreservation workflow requires high-quality, purpose-built reagents and materials. The table below details key solutions for protecting CQAs.

Table: Essential Research Reagent Solutions for Cryopreservation

| Item | Function & Rationale | Key Considerations |

|---|---|---|

| Defined Cryomedium (e.g., CryoStor) | A ready-to-use, serum-free freezing medium containing DMSO. Provides a safe, defined, and protective environment, minimizing lot-to-lot variability and contamination risks associated with homemade FBS-containing media [2]. | Essential for GMP compliance. Using a defined medium is critical for ensuring consistent production and quality control [2]. |

| DMSO-Free Formulations | Cryopreservation media using alternatives like trehalose, sucrose, or polyampholytes. Mitigates the cytotoxicity and patient side effects associated with DMSO, which is crucial for therapies administered via novel routes (e.g., intracerebral, intraocular) [16] [15]. | Often requires optimization of freezing profiles, as they may not perform well with standard -1°C/min protocols [16]. |

| Liquid Nitrogen Storage Systems | Long-term storage of cryopreserved cells at -135°C to -196°C. Dramatically reduces biological and chemical activity, ensuring long-term stability of CQAs. Short-term storage at -80°C leads to progressive viability loss [2] [19]. | Use internal-threaded cryogenic vials to prevent contamination. Ensure systems have temperature monitoring and backup for security [2]. |

| Controlled-Rate Freezer (CRF) | Equipment that precisely controls cooling rate (typically -1°C/min). Allows definition of critical process parameters to control ice nucleation and minimize intracellular ice formation, directly impacting viability and potency CQAs [4] [2]. | Requires user qualification for specific container types and load configurations. Vendor factory testing is often insufficient for cGMP use [4]. |

| Automated Thawing Device (e.g., ThawSTAR) | Provides consistent, rapid thawing at a defined rate. Eliminates variability and contamination risk from manual water bath thawing, ensuring high and consistent cell recovery [4] [18]. | Ensures bedside and GMP-thawing reproducibility, a frequent failure point in the cold chain [4]. |

Advanced Protocol: Qualification of a Controlled-Rate Freezer for CQA Consistency

Objective: To qualify a new or existing controlled-rate freezer (CRF) to ensure it provides a uniform and reproducible thermal environment for cryopreserving stem cell products, thereby minimizing inter-vial CQA variability.

Background: Relying solely on vendor certification is insufficient for a cGMP environment. This protocol establishes performance limits for your specific process conditions (vial type, fill volume, cell type) [4].

Materials:

- Controlled-rate freezer

- Validated temperature logging system (e.g., thermocouples)

- Empty cryovials of the primary container type used

- Freezing medium (e.g., CryoStor CS10)

- CRF racking system

Methodology:

- Define Operational Ranges: Determine the minimum, typical, and maximum loads (e.g., 10 vials, 50 vials, 100 vials) and configurations that will be used in production.

- Instrument Vials: Fill cryovials with freezing medium at the standard volume (e.g., 1 mL). Place temperature probes in vials located at strategic, challenged locations within the CRF chamber (e.g., top-center, bottom-corner, near the LN2 inlet). A typical mapping strategy involves a 3D grid of locations [4].

- Execute Freezing Runs: Run the standard freezing profile (e.g., -1°C/min to -80°C) for each load condition defined in Step 1. Record the temperature from every probe at frequent intervals (e.g., every 10 seconds).

- Analyze Data: For each run, analyze the data to determine:

- Temperature Uniformity: The maximum temperature difference between any two vials at any point during the run should be within a pre-defined acceptance criterion (e.g., ±3°C).

- Cooling Rate Consistency: The actual cooling rate for each vial through the critical phase (e.g., +4°C to -40°C) should match the set point within a defined range (e.g., ±0.5°C/min).

- Establish Alert and Action Limits: Based on the data, set limits for routine monitoring. If a production run shows a freeze curve that deviates beyond these limits, it can be flagged for investigation before post-thaw analytics are even available [4].

This qualification protocol directly supports the quality of your stem cell product by ensuring the process-related data from the CRF is a reliable indicator of consistent manufacturing, thereby safeguarding your CQAs.

Regulatory Landscape for Cellular Starting Materials (US, EU, and APAC perspectives)

Frequently Asked Questions (FAQs)

1. How do different regions classify the cryopreservation of cellular starting materials, and what are the regulatory consequences? The classification of cryopreservation—whether as a "minimal manipulation" or "substantial manipulation"—dictates the level of regulatory control. This classification varies by region, impacting whether Good Manufacturing Practice (GMP) standards are required.

- United States (US): Under 21 CFR 1271, cryopreservation is typically considered a minimal manipulation unless it alters relevant biological characteristics. Minimal manipulation activities are subject to less stringent regulations compared to more than minimally manipulated products [20].

- European Union (EU): The ATMP Regulation (1394/2007) and the Tissue and Cells Directive (2004/23/EC) provide the framework. Similar to the US, cryopreservation itself (freezing, cryopreservation) is generally not considered a substantial manipulation. Substantial manipulations include activities like cell expansion or genetic modification, which would classify the product as an Advanced Therapy Medicinal Product (ATMP) [21] [20].

- Asia-Pacific (APAC): Perspectives vary:

- Japan: The Good Gene, Cellular, and Tissue-based Products Manufacturing Practice (GCTP) applies. The health authority determines the impact on product quality and safety based on scientific data [20].

- Australia: Follows the Australian Code of GMP for Human Blood and Blood Components, Human Tissues and Human Cellular Therapy Products, which generally considers cryopreservation as minimal manipulation [20].

- South Korea: Governed by the Act on the Safety of and Support for Advanced Regenerative Medicine and Advanced Biological Products (ARMAB), with a perspective similar to the US and EU [20].

2. What are the key regulatory trends for Advanced Therapy Medicinal Products (ATMPs) in 2024-2025? Regulatory bodies are continuously adapting to the rapid growth of cell and gene therapies. Key recent trends include:

- US FDA Policy Shift: The FDA has eliminated the Risk Evaluation and Mitigation Strategies (REMS) for all approved BCMA- and CD19-directed autologous CAR-T cell immunotherapies. This removes requirements for special hospital certification and on-site, immediate access to tocilizumab, simplifying treatment administration [22].

- UK MHRA Innovation: New UK regulations for Modular Manufacture and Point of Care came into effect in July 2025. This allows manufacturing steps for personalized therapies like CAR-T to be performed in hospitals or local clinics, reducing patient wait times [22].

- EMA Regulatory Support: The EMA is running a pilot program to provide dedicated regulatory support, including fee reductions, to academia and non-profit organizations developing ATMPs for unmet clinical needs [23].

- Security and Data Concerns: The US FDA has announced a review of clinical trials that involve sending American citizens' cells to "hostile countries" for genetic engineering and re-infusion, highlighting growing concerns over genetic data security and patient consent [24].

3. What are the major challenges in scaling up cryopreservation processes for commercial cell therapies? Scaling cryopreservation is identified as a major hurdle for the cell and gene therapy industry [4]. Key challenges include:

- Batch Processing: The majority of respondents (75%) in an ISCT survey cryopreserve all units from an entire manufacturing batch together. This can create a bottleneck and increase the time variance between the start and end of freezing for a single batch [4].

- Process Consistency: Dividing a batch into sub-batches for sequential cryopreservation introduces a risk of freezing process variability between the sub-batches, potentially impacting product consistency [4].

- Infrastructure and Cost: Scaling requires significant investment in controlled-rate freezers, liquid nitrogen infrastructure, and specialized personnel [4].

4. Why is there a industry push towards DMSO-free cryopreservation media? While DMSO is the traditional cryoprotectant, its cytotoxicity is a significant concern, especially for sensitive cell types. DMSO-free cryosolutions offer several advantages [25]:

- Reduced Toxicity: Eliminates the risk of DMSO-induced cell damage and potential adverse effects in patients.

- Simplified Workflow: Often reduces or eliminates the need for post-thaw washing steps, saving time and improving efficiency, which is critical in high-throughput and automated settings [25].

- Improved Reproducibility: Defined, serum-free formulations reduce lot-to-lot variability compared to lab-made media containing fetal bovine serum (FBS) [2]. Challenges to adoption include higher cost, limited accessibility, and ongoing regulatory evaluations for broader clinical use [25].

Troubleshooting Guides

Problem: Poor Post-Thaw Cell Viability and Recovery

Potential Causes and Solutions

| Potential Cause | Diagnostic Checks | Corrective Action |

|---|---|---|

| Suboptimal Cooling Rate | Review controlled-rate freezer (CRF) validation records and freeze curve data [4]. | - Use a controlled cooling rate of -1°C/min [2].- Validate CRF performance across different container types and load configurations [4]. |

| Improper Thawing Technique | Confirm thawing method and rate. | Thaw cells rapidly (e.g., in a 37°C water bath) to minimize ice recrystallization damage and DMSO exposure [4] [2]. |

| Cryoprotectant Agent (CPA) Toxicity | Check CPA concentration and post-thaw washing protocol. | - Consider switching to a DMSO-free, serum-free commercial medium (e.g., CryoStor, Bambanker DMSO-Free) [25] [2].- If using DMSO, ensure concentration is optimized for your cell type (typically 5-10%) [10]. |

| Inconsistent CRF Performance | Analyze freeze curves for deviations from the set profile [4]. | - Qualify CRFs using a range of masses and container types, not just a vendor's default profile [4].- Establish alert limits for freeze curves as part of process monitoring [4]. |

Experimental Protocol: Optimizing a Cryopreservation Protocol for a New Stem Cell Line

This protocol provides a methodology to systematically develop a cryopreservation process, addressing common failure points.

Cell Harvest:

- Harvest cells during their maximum growth phase (log phase) at >80% confluency [2].

- Perform a cell count and viability assay to establish a baseline.

CPA and Media Formulation Testing:

- Prepare multiple cryomedias: Test a traditional DMSO-based medium (e.g., 10% DMSO in culture medium with FBS) against commercially available, defined alternatives (e.g., CryoStor CS10, Bambanker DMSO-Free) [2] [25].

- Resuspend cell pellets in the different cryomedias at a target concentration (e.g., 1x10^6 cells/mL).

Cooling Rate Optimization:

- Aliquot cell suspensions into cryovials.

- Freeze using different methods:

- Controlled-rate freezer: Use a standard profile (e.g., -1°C/min).

- Passive freezing containers: Place vials in a Mr. Frosty or CoolCell and store at -80°C [2].

Storage and Thawing:

- After freezing, transfer vials to long-term storage in the vapor phase of liquid nitrogen (<-135°C).

- Thaw rapidly by immersing vials in a 37°C water bath with gentle agitation until only a small ice crystal remains [2].

Post-Thaw Analysis:

- Immediately upon thawing, assess:

- Viability: Using trypan blue exclusion or flow cytometry.

- Recovery: Calculate the percentage of viable cells recovered relative to the pre-freeze count.

- Functionality: Perform a cell-type specific functional assay (e.g., differentiation potential, proliferation assay).

- Immediately upon thawing, assess:

Problem: Regulatory Compliance During Tech Transfer and Scale-Up

Potential Causes and Solutions

| Potential Cause | Diagnostic Checks | Corrective Action |

|---|---|---|

| Lack of Process Understanding | Review process development data and CRF qualification reports [4]. | - Quality CRFs for the specific container types and load configurations used in production, not just vendor defaults [4].- Use freeze curves as part of process monitoring, not just post-thaw analytics for release [4]. |

| Inadequate Quality Control (QC) | Audit QC data and batch records for completeness. | - Implement post-thaw quality assessment (e.g., viability, sterility) for every batch [10].- Ensure robust record-keeping for full traceability [2]. |

| Open vs. Closed Processing | Evaluate the cleanroom classification and environmental monitoring data. | - Implement closed system processing (e.g., sterile tubing welders) for formulation and cryopreservation to reduce contamination risk [20].- A validated closed system may allow processing in a controlled, non-classified space, reducing costs [20]. |

Experimental Protocol: Qualifying a Controlled-Rate Freezer (CRF) for cGMP Compliance

This protocol outlines key steps to qualify a CRF, addressing a major industry challenge where nearly 30% of users rely solely on vendor qualification [4].

Define User Requirements Specification (URS): Document the intended use, including common container types (vials, cryobags), fill volumes, and cell product types.

Installation Qualification (IQ): Verify the CRF is installed correctly according to manufacturer specifications.

Operational Qualification (OQ): Verify that the CRF operates within specified parameters across its defined range.

- Temperature Mapping: Perform full and empty chamber mapping across a grid of locations to identify hot/cold spots [4].

- Use thermocouples to monitor temperature uniformity.

Performance Qualification (PQ): Demonstrate the CRF performs reliably under actual production conditions.

- Simulate Production Loads: Use cryocontainers filled with a placebo solution that mimics the thermal mass of your cell product.

- Freeze Curve Mapping: Run standard and worst-case freezing profiles and monitor the freeze curves at different locations within the load [4].

- Mixed Load Testing: If applicable, test configurations with different container types frozen together to establish performance limits [4].

Documentation: Compile a qualification report summarizing all data, establishing alert and action limits for freeze curves, and defining the approved operational ranges.

The Scientist's Toolkit: Essential Reagents and Materials

Table: Key reagents and equipment for cryopreservation workflows, incorporating best practices for regulatory compliance.

| Item | Function & Regulatory Consideration | Example Products / Notes |

|---|---|---|

| Cryopreservation Media | Protects cells from ice crystal damage during freeze-thaw. Using cGMP-manufactured, defined, serum-free media is recommended for regulated applications to ensure consistency and safety [2]. | DMSO-based: CryoStor [2]DMSO-free: Bambanker DMSO-Free [25]Specialized: mFreSR (for ES/iPS cells) [2] |

| Controlled-Rate Freezer (CRF) | Provides a consistent, controlled cooling rate (typically -1°C/min), which is critical for process control and reproducibility in cGMP [4] [10]. | Must be qualified for intended use with specific container types and load configurations [4]. |

| Cryogenic Storage Vials/Bags | Primary container for long-term storage. Internal-threaded vials are preferred to prevent contamination [2]. Cryobags are common for larger volumes like PBSCs [10]. | Corning Cryogenic Vials; Various cryobag sizes (50mL - 500mL) [2] [10]. |

| Passive Freezing Containers | Provides an approximate cooling rate of -1°C/min in a standard -80°C freezer, offering a lower-cost alternative to CRFs for R&D or early-stage work [2]. | Nalgene Mr. Frosty (isopropanol-based), Corning CoolCell (isopropanol-free). |

| Liquid Nitrogen Storage | For long-term storage at <-135°C. Essential for maintaining cell viability over extended periods [2]. | Storage in the vapor phase is standard practice. |

| Closed System Equipment | Enables aseptic processing without relying on a classified cleanroom, reducing contamination risk and facility costs. Critical for minimal manipulation processes [20]. | Sterile tubing welders, closed-system cell processors. |

From Principle to Practice: Current Protocols and Industry Standards

Frequently Asked Questions (FAQs)

1. What is the current industry adoption rate for controlled-rate freezing? A 2025 survey by the ISCT Cold Chain Management & Logistics Working Group indicates high adoption, with 87% of respondents reporting the use of controlled-rate freezing for cell-based products. The remaining 13% using passive freezing have products predominantly in early clinical stages (up to phase II) [4].

2. When is controlled-rate freezing strongly preferred over passive freezing? Controlled-rate freezing is the preferred method for late-stage clinical and commercial products due to superior control over critical process parameters [4]. It is particularly crucial for sensitive cell types like iPSCs, CAR-T cells, engineered cells, and differentiated cells (hepatocytes, cardiomyocytes) that often require optimized, non-default freezing profiles [4].

3. Are there any cell types where passive freezing is sufficient? Yes. A 2025 clinical study found that for hematopoietic progenitor cells (HPCs), passive freezing outcomes were comparable to controlled-rate freezing regarding CD34+ cell viability and engraftment, suggesting it is an acceptable alternative for this cell type [26].

4. What are the primary technical challenges associated with controlled-rate freezers? Key challenges include a lack of consensus on qualification methods (with nearly 30% of users relying on vendor qualification) and underutilization of freeze curves in the release process, as many facilities still rely solely on post-thaw analytics [4].

5. Why is scaling cryopreservation a major industry hurdle? In the same 2025 survey, 22% of respondents identified the "Ability to process at a large scale" as the single biggest hurdle. Most respondents (75%) cryopreserve all units from an entire manufacturing batch together, which can create variance and present scaling challenges [4].

Troubleshooting Guides

Issue 1: Poor Post-Thaw Viability of iPSCs

Problem: Low cell survival and extended recovery time (beyond 4-7 days) after thawing induced pluripotent stem cells (iPSCs).

Solution:

- Freezing Protocol: Ensure a slow, controlled cooling rate.

- Thawing Protocol: Thaw cells rapidly.

- Pre-freezing Cell Status: Harvest cells during their maximum growth phase (log phase) and at >80% confluency for best results [2].

- Prevent Osmotic Shock: During thawing, carefully dilute out the cryoprotectant to prevent sudden osmotic stress that can further damage cells [27].

Issue 2: Inconsistent Performance Across a Controlled-Rate Freezer (CRF) Batch

Problem: Variable post-thaw results from vials frozen in the same CRF run.

Solution:

- Comprehensive Freezer Qualification:

- Do not rely solely on vendor factory testing. Perform qualification based on your specific use case [4].

- The qualification protocol should include a range of masses, container configurations, and temperature profiles [4].

- Perform temperature mapping across a grid of locations and freeze curve mapping for different container types to identify hot or cold spots [4].

- Utilize Freeze Curves for Process Control:

- Implement monitoring of freeze curves for every run. Establish action or alert limits to identify deviations in CRF performance before they lead to critical failures [4].

Issue 3: Choosing Between Controlled-Rate and Passive Freezing for a New Product

Problem: Deciding on a cryopreservation strategy early in process development.

Solution:

- Weigh the pros and cons based on your product's needs and development stage. The table below summarizes key considerations [4]:

| Factor | Controlled-Rate Freezing | Passive Freezing |

|---|---|---|

| Process Control | High control over critical parameters (e.g., cooling rate) [4]. | Lack of control over critical process parameters [4]. |

| Product Consistency | Effective tool for controlling quality and consistency [4]. | Advanced technology may be needed to mitigate freezing damage [4]. |

| Cost & Infrastructure | High cost (instrument, liquid nitrogen, staffing) [4]. | Low-cost, low-consumable infrastructure [4]. |

| Operational Complexity | Specialized expertise required [4]. | Simple, one-step operation; low technical barrier [4]. |

| Scaling | Can be a bottleneck for batch scale-up [4]. | Ease of scaling [4]. |

| Best Application | Late-stage clinical and commercial products; sensitive cell types [4]. | Early R&D and early clinical stages (up to phase II); robust cell types [4]. |

- Consider the impact of process changes: Adopting controlled-rate freezing early on can avoid the significant effort of making a major manufacturing change later and establishing product comparability [4].

Adoption Rates and Resource Allocation

The following table consolidates key quantitative findings from recent industry surveys and research [4]:

| Metric | Finding | Context / Implication |

|---|---|---|

| Adoption of Controlled-Rate Freezing | 87% | High prevalence in cell and gene therapy industry [4]. |

| Use of Default Freezer Profiles | 60% | Remaining 40% require optimized profiles for sensitive cells [4]. |

| Resources Dedicated to Cryopreservation/Post-Thaw Analytics | 33% | This area faces the most challenges and attracts the most R&D effort [4]. |

| Biggest Hurdle: Large-Scale Processing | 22% | Identified as the single largest challenge to overcome [4]. |

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function | Application Note |

|---|---|---|

| CryoStor CS10 | A ready-to-use, serum-free cryopreservation medium containing 10% DMSO. | Provides a safe, protective environment; suitable for a wide variety of cell types and recommended for GMP workflows [2] [29]. |

| mFreSR | A defined, serum-free freezing medium. | Optimized for cryopreserving human embryonic and induced pluripotent stem cells (ES and iPS cells) [2]. |

| Dimethyl Sulfoxide (DMSO) | A permeating cryoprotectant agent (CPA). | Prevents ice crystal formation by penetrating cells; standard concentration is 5-10% [27] [16]. |

| Rho Kinase (ROCK) Inhibitor (Y-27632) | A small molecule that improves cell survival after thawing. | Often added to culture medium post-thaw to enhance attachment and survival of sensitive cells like iPSCs [29]. |

| Ficoll 70 | A non-permeating polymer. | Can be added to freezing solution to enable potential long-term storage of iPSCs at -80°C [27]. |

Experimental Protocol for Controlled-Rate Freezing

This is a generalized detailed protocol for cryopreserving cells using a controlled-rate freezer, compiled from industry standards [2].

Cell Harvesting:

- Harvest cells during the logarithmic growth phase at >80% confluency.

- Centrifuge the cell suspension and carefully remove the supernatant.

Resuspension in Freezing Medium:

- Resuspend the cell pellet in an appropriate, pre-cooled cryopreservation medium (e.g., CryoStor CS10) at a specific concentration. Typical concentrations range from 1x10^3 to 1x10^6 cells/mL.

- Note: It is good practice to test freezing at multiple concentrations to determine the optimum for your cell type.

Aliquoting:

- Aliquot the cell suspension into cryogenic vials. Using internal-threaded vials is preferable to prevent contamination.

Controlled-Rate Freezing:

Long-Term Storage:

Cryopreservation Strategy Decision Workflow

Cell Freezing Experimental Workflow

DMSO Concentration Guide and Safety Profile

Table 1: Clinical DMSO Concentration Guidelines for Cell Therapy Products

| Cell Type | Common DMSO Concentration | Key Comparative Findings | Reported Post-Thaw Viability | Primary Safety Concerns |

|---|---|---|---|---|

| Hematopoietic Stem Cells (HSCs) [31] | 10% (Standard) | Higher infusional toxicity | -- | Nausea, vomiting, cardiac events [31] |

| Hematopoietic Stem Cells (HSCs) [31] | 5% (Reduced) | Improved CD34+ cell viability, reduced side effects | -- | Significantly reduced adverse effects [31] |

| Mesenchymal Stromal Cells (MSCs) [32] [33] | ~10% (Standard) | Doses 2.5-30x lower than 1 g/kg deemed acceptable [32] [33] | -- | Isolated infusion-related reactions with premedication [32] [33] |

| hiPSC-Derived Cardiomyocytes [34] | 10% (Conventional) | Lower performance vs. DMSO-free cocktails | 69.4% ± 6.4% | Functional alterations, epigenetic effects [34] |

DMSO-Free Cryoprotectant Formulations

Table 2: Experimentally Validated DMSO-Free Formulations

| Cell Type | DMSO-Free Formulation | Post-Thaw Viability/Recovery | Key Advantages |

|---|---|---|---|

| hiPSC-Derived Cardiomyocytes [34] | Cocktail of Trehalose, Glycerol, Isoleucine | >90% recovery [34] | Preserved function, avoids DMSO toxicity & epigenetic effects [34] |

| Mesenchymal Stromal Cells (MSCs) [32] | 30 mM Sucrose + 5% Glycerol + 7.5 mM Isoleucine | 83% Viability, 93% Recovery [32] | Serum-free, defined composition [32] |

| Adipose Tissue MSCs [32] | 3% Trehalose + 5% Dextran 40 + 4% Polyethylene Glycol | ~95% Viability, ~95% Recovery [32] | High efficiency, non-penetrating CPAs [32] |

| Embryonic Stem Cell-Derived MSCs [32] | 150 mM Sucrose + 300 mM Ethylene Glycol + 30 mM Alanine + 0.5 mM Taurine + 0.02% Ectoine | 96% Viability, 103% Recovery [32] | Complex cocktail mimicking intracellular environment [32] |

Experimental Protocols

Differentiation and Purification:

- Culture hiPSCs to 80-90% confluency.

- Initiate cardiac differentiation using 6.5 µM CHIR99021 in RPMI/B-27 minus insulin medium for 48 hours.

- On Day 2, replace medium with RPMI minus supplemented with 5 µM IWP2.

- On Day 8, switch to RPMI/B-27 maintenance medium.

- Between Days 10-14, purify cardiomyocytes using glucose-free DMEM with 4 mM sodium L-lactate.

Freezing Process:

- Harvest cardiomyocytes on Days 14-16 using 0.25% Trypsin-EDTA.

- Resuspend in recovery medium (RPMI/B-27 with 20% FBS and 5 µM ROCK inhibitor Y-27632) for 30 minutes.

- Prepare the optimized DMSO-free cryoprotectant solution.

- Mix the cell suspension with the cryoprotectant.

- Use a controlled-rate freezer with the following parameters:

- Store cryovials at -80 °C or in liquid nitrogen.

Tissue Processing and Crypt Isolation:

- Collect human colorectal tissue samples under sterile conditions and IRB approval.

- Transfer samples in cold Advanced DMEM/F12 medium supplemented with antibiotics.

- For short-term delays (≤6-10 hours), wash tissues with antibiotic solution and store at 4°C.

- For longer delays, cryopreserve tissue pieces in freezing medium (e.g., 10% FBS, 10% DMSO in 50% L-WRN conditioned medium).

- Isolate crypts from the processed tissue through mechanical and enzymatic dissociation.

Organoid Culture and Cryopreservation:

- Embed isolated crypts in Matrigel droplets.

- Culture with specialized medium containing growth factors (EGF, Noggin, R-spondin).

- For cryopreservation, harvest organoids and resuspend in an appropriate freezing medium (e.g., 10% DMSO in FBS or a commercial serum-free alternative).

- Freeze at a controlled rate of -1 °C/min or using a -80 °C freezer overnight before transferring to liquid nitrogen for long-term storage.

Troubleshooting Common Cryopreservation Issues

FAQ 1: How can I reduce DMSO-related toxicity in cell therapy products?

- Strategy A: Reduce DMSO Concentration. For autologous HSC transplants, reducing DMSO from 10% to 5% in the freezing medium improves post-thaw CD34+ cell viability and significantly reduces adverse effects in patients, such as nausea and vomiting, without negatively impacting engraftment [31].

- Strategy B: Implement Post-Thaw Washing. Remove the cryoprotectant after thawing by centrifuging the cell product and resuspending it in a compatible solution like normal saline or plasma. Note that this can lead to cell loss and requires careful handling [31].

- Strategy C: Use DMSO-Free Formulations. For research applications, adopt validated DMSO-free media. These formulations use combinations of sugars, sugar alcohols, and amino acids to protect cells, eliminating DMSO-related toxicity concerns entirely [25] [34].

FAQ 2: What are the critical parameters for optimizing controlled-rate freezing? The cooling rate and nucleation temperature are crucial. For example, in hiPSC-derived cardiomyocytes, a rapid cooling rate of 5 °C/min and a low nucleation temperature of -8 °C were found to be optimal, achieving post-thaw recoveries over 90% with a DMSO-free formulation [34]. The optimal parameters are cell-type specific and must be determined experimentally.

FAQ 3: Why is post-thaw cell viability low even with high viability pre-freeze? This can be due to several factors:

- Suboptimal Cooling Rate: An incorrect cooling rate causes lethal intracellular ice formation or excessive osmotic stress [34].

- Improper Thawing Technique: Rapid thawing at 37°C is standard, but uneven thawing or failure to promptly dilute cryoprotectants can damage cells [35].

- Cryoprotectant Toxicity: DMSO exposure time and temperature post-thaw are critical; prolonged exposure at room temperature is toxic [34] [35].

- Cell-Type Specific Sensitivity: Some primary cells and stem cells are inherently more sensitive to cryopreservation stresses and may require tailored formulations [25] [34].

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagents for Cryopreservation Research

| Reagent / Solution | Function | Example Use Cases |

|---|---|---|

| DMSO (Dimethyl Sulfoxide) [32] [31] | Penetrating cryoprotectant; prevents intracellular ice formation. | Standard cryopreservation of HSCs, MSCs, and many cell lines. |

| Trehalose [32] [34] | Non-penetrating cryoprotectant; stabilizes cell membranes and proteins. | Key component in many DMSO-free formulations for MSCs and hiPSC-CMs [32] [34]. |

| Glycerol [32] [34] | Penetrating cryoprotectant; less toxic alternative to DMSO for some cell types. | Used in DMSO-free cocktails for MSCs and hiPSC-CMs [32]. |

| ROCK Inhibitor (Y-27632) [29] | Enhances cell survival by inhibiting apoptosis following dissociation and freezing. | Added to recovery medium post-thaw for hiPSCs and sensitive primary cells [29]. |

| CryoStor CS10 [29] | A proprietary, serum-free, GMP-compliant cryopreservation solution containing 10% DMSO. | Used in clinical-grade cell therapy products and research for improved, standardized recovery [29]. |

| Bambanker DMSO-Free [25] | A commercial, serum-free, DMSO-free cryopreservation medium. | Provides a ready-to-use, defined solution for sensitive cells like stem cells and primary cells [25]. |

Visualizing Cryopreservation Workflows and Strategies

DMSO-Free Formulation Development

Post-Thaw Cell Processing Decision Guide

For researchers and drug development professionals working with personalized stem cell products, the post-thaw phase is a critical determinant of experimental success and therapeutic efficacy. The period immediately following the removal of cells from cryostorage represents a vulnerable window where processing decisions directly impact cell fitness, function, and suitability for downstream applications. This technical support center addresses the key challenges in post-thaw processing, providing evidence-based troubleshooting guidance to navigate the inherent trade-offs between cell purity, recovery yield, and functional integrity. The following sections offer detailed protocols, comparative data, and strategic frameworks to optimize your post-thaw workflows within the broader context of advancing cryopreservation research for stem cell-based therapies.

FAQs: Navigating Post-Thaw Processing Decisions

What is the fundamental trade-off between purity and recovery in post-thaw processing?

There is an inherent inverse relationship between the purity of your target cell population and the total number of cells you recover post-thaw. Methods designed to achieve high purity, such as bead-based depletion or specialized isolation kits, typically involve more processing steps that can mechanically stress cells or require longer handling times, leading to greater overall cell loss. Conversely, simpler methods like wash-only protocols maximize total cell recovery but retain more unwanted cell populations and debris, which can interfere with downstream applications [13] [36].

How does the choice of post-thaw method impact long-term cell function?

The processing method selected immediately after thawing can significantly influence cell fitness days later. For instance, in cord blood mononuclear cells (CBMCs), the EasySep Direct Human PBMC Isolation Kit yielded the highest percentage of viable cells on Day 0. However, when cells were cultured for five days, the Beads (CD15/CD235 depletion) method demonstrated superior preservation of viability under stimulation [13] [37]. Some methods that enhance initial purity may inadvertently remove critical supportive cells; the PBMC Isolation Kit's depletion of CD14+ cells was correlated with reduced T-cell proliferation, highlighting a functional trade-off [36].

My post-thaw viability is good, but the cells fail to expand in culture. What could be wrong?

Good viability immediately post-thaw, as measured by assays like trypan blue exclusion, primarily indicates membrane integrity. Failure to expand suggests underlying functional deficits not captured by basic viability tests. Potential causes include:

- Cryo-induced Apoptosis: Cryopreservation can trigger programmed cell death. Consider implementing an apoptosis assay, such as the Live, Apoptosis-Negative (LAN) assay, validated for post-thaw cells [13].

- Metabolic or Mitochondrial Damage: The freezing process can damage mitochondria. Assessing metabolic activity (e.g., with a colony-forming unit assay) or mitochondrial membrane potential can provide a deeper functional readout [13] [38].

- Improper Pre-freeze Handling: The cell growth phase before freezing is critical. Cells should be harvested during their maximum growth phase (log phase) and at high confluency (>80%) to ensure robust recovery [39] [2].

Are there alternatives to chemical cryoprotectants like DMSO to improve post-thaw fitness?

Yes, research is actively exploring DMSO-free solutions and physical methods to mitigate cryodamage. Photobiomodulation (PBM), the application of specific light wavelengths, has shown promise as a non-chemical, post-thaw intervention. One study found that irradiating thawed human stem cells with 950 nm near-infrared light at 30 Hz and a 30% duty cycle reduced apoptosis and reactive oxygen species (ROS), while increasing mitochondrial membrane potential and ATP generation [38]. Furthermore, DMSO-free cryoprotectant cocktails using naturally occurring osmolytes (e.g., trehalose, glycerol, isoleucine) have been developed for hiPSC-derived cardiomyocytes, achieving post-thaw recoveries over 90% [34].

Troubleshooting Guides

Problem: Low Cell Yield After Post-Thaw Processing

| Possible Cause | Diagnostic Steps | Recommended Solution |

|---|---|---|

| Excessive processing | Compare cell counts after thawing and after each processing step. | Simplify the protocol. If high purity is not immediately required, use a wash-only method and perform isolation after a short period in culture [13]. |

| Osmotic shock during DMSO removal | Check protocol for direct dilution. Observe cell morphology for swelling or lysis. | Use a sequential dilution method. Gently add warm culture medium dropwise to the cell suspension while gently mixing to gradually reduce DMSO concentration [39]. |

| Overly aggressive centrifugation | Review speed and duration of spin. | Optimize centrifugation force and time. Use the lowest possible g-force and shortest time adequate for pelleting the specific cell type (e.g., 160g for 18 min for PBSCs) [40]. |

| Incorrect cell concentration | Count cells before cryopreservation. | Aim for a general range of 1x10^3 to 1x10^6 cells/mL in the cryovial. Test multiple concentrations to find the optimum for your cell type [2]. |

Problem: Poor Functional Outcomes Despite High Viability

| Possible Cause | Diagnostic Steps | Recommended Solution |

|---|---|---|

| Loss of critical accessory cells | Use flow cytometry to characterize immune subset composition pre-freeze and post-processing. | Switch to a gentler or more specific purification method. If using a kit that depletes CD14+ monocytes, be aware this may impair T-cell function [36]. |

| Residual cryoprotectant toxicity | Note the DMSO concentration during culture. | Ensure thorough but gentle washing post-thaw. For sensitive applications, consider DMSO-free cryopreservation formulations [34]. |

| Mitochondrial dysfunction | Perform a metabolic activity assay (e.g., MTT) or measure ROS and ATP levels [38]. | Incorporate a recovery period with antioxidants or consider non-invasive PBM to boost mitochondrial function post-thaw [38]. |

| Cryo-induced senescence | Check for enlarged, flat morphology and low proliferation rates. | Ensure cells are frozen in the log growth phase and use early-passage cells for critical applications [39]. |

Experimental Protocols & Data

Comparative Analysis of Post-Thaw Processing Methods for CBMCs

The following table summarizes quantitative outcomes from a systematic study comparing four post-thaw processing methods for cord blood mononuclear cells, illustrating the key trade-offs [13] [36].

| Processing Method | CBMC Recovery Yield | Purity (Depletion of Non-Target Cells) | Day 0 Viability (LAN Cells) | Day 5 Viability After Stimulation |

|---|---|---|---|---|

| Wash-Only | Highest | Lowest | Moderate | Moderate |

| Density Gradient | Moderate | Moderate | Moderate | Moderate |

| CD15/CD235 Bead Depletion | Low | Highest | Moderate | Best Preserved |

| EasySep PBMC Isolation Kit | Low | Highest | Highest | Low (Reduced T-cell prolif.) |

Detailed Protocol: Post-Thaw Processing via Density Gradient

This protocol is adapted for processing volume-reduced cord blood units after thawing [36].

Materials:

- Thawed CBU sample

- DPBS (Dulbecco's Phosphate Buffered Saline), without calcium and magnesium

- Ficoll-Paque PLUS or similar density gradient medium

- Good Manufacturing Practice (GMP)-grade Dextran

- Centrifuge with swing-bucket rotor

- Sterile serological pipettes

- Processing tube (e.g., 50 mL conical tube)

Method:

- Dilution: Gently dilute the thawed CBU sample with an equal volume of DPBS supplemented with 1% GMP-grade Dextran. Mix gently by inversion.

- Layer: Carefully layer the diluted cell suspension over the Ficoll-Paque medium in a 2:1 ratio (e.g., 30 mL diluted cells over 15 mL Ficoll) without disrupting the interface.

- Centrifugation: Centrifuge at 800g for 20-30 minutes at room temperature, with the brake turned off. This is critical for a clean separation.

- Harvest MNCs: After centrifugation, carefully aspirate the upper plasma/platelet layer. Using a sterile pipette, transfer the mononuclear cell layer (the cloudy interface between the plasma and Ficoll) to a new sterile tube.

- Wash: Resuspend the harvested cells in a large volume (e.g., 3-4 times the volume collected) of DPBS. Centrifuge at 300g for 10 minutes to wash the cells.

- Final Resuspension: Aspirate the supernatant and resuspend the cell pellet in an appropriate culture medium or buffer for counting and subsequent use.

Workflow Diagram: Post-Thaw Processing Decision Pathway

The following diagram outlines a logical workflow for selecting an appropriate post-thaw processing strategy based on your primary experimental objective.

The Scientist's Toolkit: Essential Reagents & Materials

| Item | Function & Application | Key Considerations |

|---|---|---|

| Dextran (GMP-grade) | Sedimentation agent used in dilution buffers for density gradient separation to improve cell recovery [36]. | Using GMP-grade reagents enhances protocol standardization and is critical for therapeutic applications. |

| EasySep Direct Human PBMC Isolation Kit | Immunomagnetic negative selection kit for high-purity isolation of PBMCs post-thaw [13] [37]. | Excellent for Day 0 viability but may deplete critical CD14+ cells, impacting long-term T-cell function. |

| CD15/CD235 Depletion Beads | Immunomagnetic beads for specifically removing granulocytes and red blood cells from thawed samples [13]. | Superior for preserving long-term cell viability and function over 5 days in culture. |

| Ficoll-Paque PLUS | Density gradient medium for isolating mononuclear cells based on buoyant density [36]. | A standard, well-established method. Ensure the brake is turned off during centrifugation for optimal separation. |

| CryoStor CS10 | A commercially available, serum-free, GMP-manufactured cryopreservation medium containing 10% DMSO [2]. | Provides a defined, protective environment, reducing lot-to-lot variability compared to lab-made FBS/DMSO mixtures. |

| Photobiomodulation Device | Applies specific near-infrared light (e.g., 950nm) to reduce ROS and apoptosis, and boost mitochondrial function post-thaw [38]. | A novel, non-chemical intervention. Parameters like frequency (30Hz) and duty cycle (30%) are critical for efficacy. |

| DMSO-Free CPA Cocktails | Mixtures of osmolytes (e.g., Trehalose, Glycerol, Isoleucine) to replace DMSO, avoiding its toxicity and epigenetic effects [34]. | Can achieve >90% recovery for sensitive cells like hiPSC-CMs. Requires optimization of composition and cooling rates. |

Best Practices for Ultra-Low Temperature Storage and Cold Chain Management

Troubleshooting Guides

Problem: Low Post-Thaw Cell Viability

Issue: Stem cells show poor recovery and viability after thawing, characterized by low attachment rates and failure to form colonies.

Investigation & Resolution:

- Audit Your Freezing Protocol: Ensure cells were frozen at a controlled rate of approximately -1°C/minute, which is critical for most cell types, including iPSCs [2] [27]. Verify the use of a proper freezing container (e.g., isopropanol-based Mr. Frosty or alcohol-free CoolCell) placed in a -80°C freezer before transfer to long-term storage [2] [3].

- Check Cell Health and Confluency Pre-Freeze: Cells must be harvested during their maximum growth phase (log phase) at >80% confluency and confirmed to be free of microbial contamination (e.g., mycoplasma) before freezing [2] [3].

- Review Cryoprotectant Agent (CPA): The standard is 5-10% DMSO [15]. To reduce DMSO cytotoxicity, consider using commercially available, serum-free, defined freezing media (e.g., CryoStor CS10, mFreSR) or supplementing your medium with non-permeable CPAs like sucrose or trehalose [2] [15].

- Validate Thawing Technique: Thaw cells rapidly by placing cryovials in a 37°C water bath until only a small ice crystal remains [2] [3]. Immediately after thawing, dilute the cell suspension drop-wise into pre-warmed culture medium to minimize osmotic shock and gently pellet the cells to remove the CPA-containing supernatant [3].

Problem: Temperature Excursions During Storage or Transport

Issue: Data loggers or monitoring systems record temperatures rising above the acceptable range for your stored or shipped products.

Investigation & Resolution:

- Confirm Storage Equipment Performance: For ultra-low (-80°C) or cryogenic (≤ -135°C) storage, qualify equipment with regular validation and temperature mapping. Ensure redundant power systems (e.g., backup generators) and continuous monitoring with real-time alerts are in place [41] [42].

- Inspect Storage Vials: Use internally-threaded cryogenic vials to minimize the risk of contamination, especially when stored in liquid nitrogen [2] [3].

- Audit Shipping and Handling Procedures:

- Packaging: Use validated thermal shipping systems. For long journeys or ultra-cold temperatures, select packaging with sufficient dry ice or active cooling containers to maintain temperature for the entire duration, including potential delays [41].

- Monitoring: Equip all shipments with real-time temperature loggers and GPS trackers. Establish clear contingency plans for interventions if alerts are triggered [41] [43].

- Training: Ensure all personnel are trained in the safe handling of dry ice and proper procedures for moving materials [41].

Problem: iPSCs Fail to Form Colonies Post-Thaw

Issue: Specific to induced pluripotent stem cells (iPSCs); cells attach but do not proliferate or form characteristic colonies.

Investigation & Resolution:

- Optimize Freezing and Thawing as Cell Aggregates: iPSCs are particularly vulnerable. Freezing and thawing them as small, defined aggregates (clumps) rather than single cells can improve recovery by preserving cell-cell contacts [27].

- Prevent Osmotic Shock During Thawing: The rapid dilution of CPAs post-thaw is a critical step for sensitive iPSCs. Slowly and gently diluting the thawed cell suspension drop-wise into a larger volume of warm medium is essential [27].

- Ensure Proper Seeding Density: Plate thawed iPSCs at a high density (e.g., 2x10^5 - 1x10^6 viable cells per well of a 6-well plate) on a Matrigel-coated surface to support attachment and colony formation [3].

- Assess Pre-Freeze Culture Health: Feed iPSC cultures daily before cryopreservation and freeze during the 2-4 day window after passaging. Avoid using overgrown or unhealthy cultures [3].

Frequently Asked Questions (FAQs)

Q1: What is the fundamental principle behind "slow freeze, rapid thaw"? The principle balances two main causes of cell damage. Slow freezing (at about -1°C/min) allows water to gradually exit the cell, minimizing the formation of lethal intracellular ice crystals that mechanically damage membranes and organelles [27] [15]. Rapid thawing (in a 37°C water bath) quickly passes through the dangerous temperature zone where ice recrystallization can occur, reducing exposure to concentrated solutes and cytotoxic cryoprotectants like DMSO [2] [15] [3].

Q2: How can I reduce or replace DMSO in my freezing media for clinical applications? Strategies include:

- Combination with other CPAs: Supplementing a lower concentration of DMSO (e.g., 5%) with non-permeable agents like sucrose, trehalose, or hydroxyethyl starch can provide synergistic protection, allowing for DMSO reduction [15].

- Using defined, commercial media: Several GMP-manufactured, serum-free, and xeno-free freezing media (e.g., CryoStor series) are optimized to be effective while mitigating DMSO-related toxicity [2].

- Novel CPA exploration: Polymers like polyvinylpyrrolidone (PVP) and methylcellulose have shown promise as partial or complete replacements for DMSO in some stem cell types [3].

Q3: What are the critical temperature thresholds for long-term storage of stem cells? For true long-term storage, temperatures at or below the glass transition temperature (Tg') of the system (around -123°C for DMSO) are required, where all molecular motion and damaging biochemical reactions cease [27]. Storage in the vapor phase of liquid nitrogen (typically -135°C to -180°C) or in ultra-low -150°C mechanical freezers is recommended [27] [3]. Storage at -80°C is acceptable only for short periods (e.g., <1 month) as cell viability will decline over time [2].

Q4: What are the key parameters to monitor for cold chain compliance? A robust cold chain monitoring system should track and document:

- Temperature continuously, with setpoints and alarms for excursions.

- Location via GPS for shipments.

- Chain of custody, including all hand-off points.

- Equipment performance (e.g., freezer/fridge metrics, backup power status) [44] [41] [43].

Q5: What are the main types of cryodamage and how do they manifest?

- Osmotic Damage: Caused by water leaving the cell during freezing, leading to harmful solute concentration and cell shrinkage [15].

- Mechanical Damage: Resulting from the physical shearing of cell membranes and organelles by intracellular and extracellular ice crystals [27] [15].

- Oxidative Damage: Caused by the generation of reactive oxygen species (ROS) during the freezing/thawing process, leading to oxidation of lipids, proteins, and DNA [15].

Experimental Protocols & Data

Standardized Freezing and Thawing Protocol for Cell Aggregates

This protocol is adapted for freezing stem cells, particularly iPSCs, as small aggregates to enhance post-thaw recovery [2] [27] [3].

Materials:

- Healthy, log-phase cells (~80-90% confluent)

- Appropriate cell culture medium

- Cryopreservation medium (e.g., with 10% DMSO or commercial alternative)

- Cryogenic vials

- Controlled-rate freezing container (e.g., CoolCell) or programmable freezer

- -80°C freezer

- Long-term storage unit (liquid nitrogen vapor phase or -150°C freezer)

- 37°C water bath

- Centrifuge

Methodology:

Freezing: