Optimizing Post-Thaw Stem Cell Viability: A 2025 Guide for Enhanced Recovery in Research & Therapy

This article provides a comprehensive guide for researchers and drug development professionals on the critical factors influencing stem cell viability and recovery after cryopreservation.

Optimizing Post-Thaw Stem Cell Viability: A 2025 Guide for Enhanced Recovery in Research & Therapy

Abstract

This article provides a comprehensive guide for researchers and drug development professionals on the critical factors influencing stem cell viability and recovery after cryopreservation. Covering foundational principles, advanced methodological protocols, and systematic troubleshooting, it synthesizes current best practices for optimizing post-thaw outcomes. The content explores the balance between intracellular ice formation and cell dehydration, details controlled-rate freezing and thawing techniques, and validates strategies through industry survey data and comparative analytics. The goal is to equip scientists with actionable knowledge to improve cell fitness, ensure experimental reproducibility, and enhance the efficacy of cell-based therapies.

The Science of Cell Survival: Understanding Cryopreservation Fundamentals

Fundamental Mechanisms and FAQs

FAQ: What are the primary competing risks of cellular damage during cryopreservation? The two principal competing risks are intracellular ice formation (IIF) and excessive cell dehydration. During freezing, ice forms outside the cell first. This increases the solute concentration in the remaining liquid, creating an osmotic pressure difference that draws water out of the cell—a process known as dehydration. A slow cooling rate allows time for this water to exit, preventing deadly intracellular ice. However, if the cooling is too slow, excessive dehydration occurs, leading to a harmful increase in intracellular solute concentration and cell shrinkage. Conversely, if cooling is too fast, water does not have time to exit and freezes inside the cell, forming intracellular ice crystals that can disrupt organelles and the cell membrane, which is almost always fatal [1] [2] [3].

FAQ: How does the ice nucleation temperature influence cell survival? Controlling the temperature at which ice nucleates extracellularly (Tnuc) is critical. Research on Jurkat T-cells shows that a higher Tnuc, closer to the solution's equilibrium freezing point (e.g., -6°C), is beneficial. This promotes more extensive intracellular dehydration during the freezing process, which in turn leads to less intracellular ice formation and results in higher post-thaw cell membrane integrity and viability, compared to a lower Tnuc (e.g., -10°C) or uncontrolled nucleation [1].

FAQ: What role does the warming rate play? The warming rate is crucial, particularly in preventing damage from recrystallization. During slow warming, small intracellular ice crystals can melt and refreeze into larger, more damaging crystals. A rapid warming rate is therefore preferred to minimize the time spent in temperature zones where this recrystallization occurs, thereby reducing damage to the cell membrane [2] [3]. Computational models suggest that for some cell types, adding a high-power pulse at the start of warming can further mitigate recrystallization effects [3].

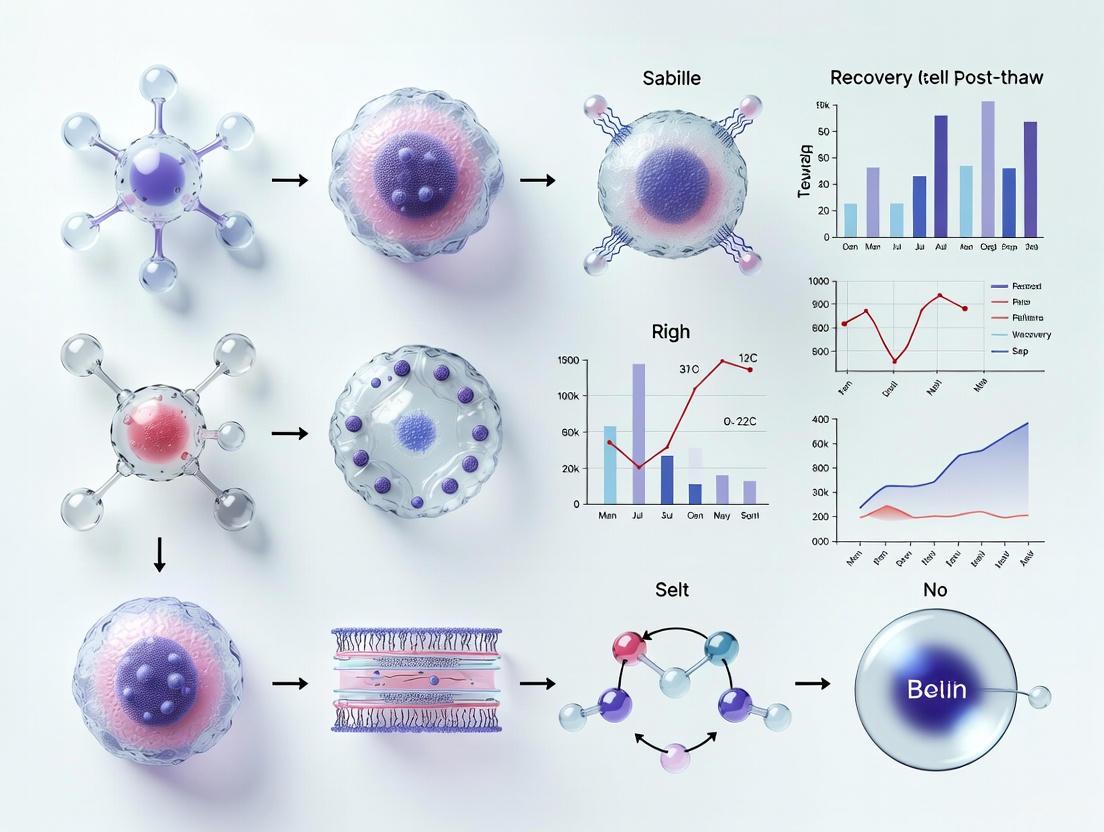

The following diagram illustrates the core principles and competing risks during the freeze-thaw cycle:

Quantitative Parameters and Data

Table 1: Impact of Controlled Ice Nucleation on T-Cell (Jurkat) Outcomes [1]

| Nucleation Temperature | Intracellular Dehydration | Intracellular Ice Formation | Post-Thaw Viability |

|---|---|---|---|

| -6°C (Controlled) | High | Low | High |

| -10°C (Controlled) | Moderate | Moderate | Moderate |

| Uncontrolled (Spontaneous) | Low | High | Low |

Table 2: Recommended Cooling Rates for Different Cell Types [2] [3]

| Cell Type | Optimal Cooling Rate | Key Consideration |

|---|---|---|

| Mouse Oocytes | 0.5 - 1.0 °C/min | Modeled to minimize intracellular ice volume and solute damage [3]. |

| Many Mammalian Cells | ~1 °C/min | A standard slow rate to balance dehydration and IIF [2]. |

| T-Cells (Jurkat) | ~1 °C/min (Starting) | Often part of a multi-step protocol [1]. |

Table 3: Comparison of Post-Thaw Processing Methods for Cord Blood Mononuclear Cells [4] [5]

| Processing Method | Purity | CBMC Yield | Key Functional Outcome |

|---|---|---|---|

| Wash-Only | Low | High | Highest cell yield, but lowest purity due to contaminants. |

| Density Gradient | Moderate | Moderate | Standard method for purity and recovery. |

| Beads (CD15/CD235 depletion) | High | Moderate | Best preserved cell viability over 5 days of stimulation. |

| EasySep PBMC Isolation Kit | High | Moderate | Highest initial viability (LAN cells); significantly depletes CD14+ cells. |

Troubleshooting Common Experimental Issues

FAQ: Our post-thaw stem cell viability is low, but we use a standard protocol. What could be wrong? Beyond the cooling rate, several factors can degrade recovery. First, examine your graft composition. For hematopoietic stem cells, extreme concentrations of platelets (both very low and very high) in the product have been correlated with reduced post-thaw CD34+ cell recovery [6]. Second, evaluate your post-thaw processing. The choice of method involves a trade-off: a simple "wash-only" step gives the highest yield but lower purity, while bead-based depletion or specific isolation kits offer higher purity and can better preserve long-term T-cell function, which is critical for cell therapy applications [4] [5]. Third, ensure your storage conditions are stable. Physical disturbances during storage (e.g., "pick-and-place" of vials) can induce recrystallization. It is recommended to store below -160°C and limit handling time to under 90 seconds to mitigate this risk [3].

FAQ: How can we reduce the cytotoxic effects of Cryoprotective Agents (CPAs) like DMSO? This is a major research focus. Promising strategies include:

- Controlled Ice Nucleation: Using a defined nucleation temperature can improve post-thaw recovery, potentially allowing for a reduction in the required CPA concentration for some cell types [1].

- Novel CPA Formulations: Research into nature-inspired antifreeze peptides (AFpeps) is ongoing. These compounds are biocompatible, can inhibit ice growth, and some variants possess additional cell-penetrating, antioxidant, or antimicrobial properties, offering a multi-functional alternative to conventional CPAs [7].

- Optimized CPA Loading/Unloading: Following precise, multi-step protocols for adding and removing CPAs can minimize osmotic shock and toxicity [2].

The workflow below outlines a systematic approach to diagnosing and resolving low post-thaw viability:

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for Cryopreservation Research

| Reagent / Tool | Function | Example & Notes |

|---|---|---|

| Permeating CPAs | Penetrate cells, reduce IIF by replacing water, and mitigate solute effects. | DMSO (most common, but has toxicity concerns); Glycerol [8] [7]. |

| Non-Permeating CPAs | Remain outside cells, providing osmotic balance and extracellular protection. | Sucrose, Trehalose, HES (Hydroxyethyl starch) [4] [7]. |

| Antifreeze Peptides (AFpeps) | Novel, bio-inspired CPAs that inhibit ice growth, reduce freezing point, and offer low toxicity. | Synthetic or insect-derived AFpeps form round crystals and are broad-spectrum; marine/plant AFpeps form sharp crystals, potentially useful for cryosurgery [7]. |

| Bead-based Depletion Kits | For post-thaw processing to remove specific contaminants (e.g., RBCs, granulocytes) and improve purity. | CD15/CD235 depletion beads; shown to best preserve long-term T-cell viability in cord blood [4] [5]. |

| Controlled Rate Freezers | Precisely control cooling rates to systematically navigate the dehydration-IIF balance. | Enables protocols with steps (e.g., hold for nucleation) and is commercially relevant for cell therapy [1]. |

| Plasma-Lyte A | A balanced salt solution used as a base for formulating cryomedicine. | Used in commercially relevant cryoformulations for T-cells [1]. |

Fundamental Mechanisms of DMSO Action

What is the primary cryoprotective mechanism of Dimethyl Sulfoxide (DMSO)?

DMSO provides cryoprotection through a combination of colligative properties and specific molecular interactions. As a penetrating cryoprotectant, DMSO enters cells and reduces the freezing point of intracellular solutions, thereby minimizing intracellular ice formation which is typically lethal to cells. Recent molecular dynamics simulations using updated AMBER force fields reveal that at low concentrations (1.5-10 vol%), DMSO's protective action arises mainly from modulation of water and ice behavior rather than direct perturbation of lipid bilayers. DMSO slows ice crystal growth by approximately a factor of five and gets excluded from the ice lattice, accumulating at ice-membrane interfaces to form protective, ice-free layers [9].

How does DMSO interact with cell membranes at the molecular level?

DMSO exhibits a complex relationship with lipid membranes. Contrary to some earlier simulation studies that exaggerated DMSO-membrane interactions, recent research indicates that low concentrations of DMSO (1.5-10 vol%) cause negligible changes to membrane thickness, area per lipid, hydration, or acyl-chain order. DMSO shows mild enrichment at the hydrophobic-hydrophilic interface of membranes, particularly near carbonyl and glycerol groups, but most molecules remain in the solvent phase. This represents an improvement in understanding over earlier models and aligns better with experimental evidence [9].

Osmotic Stress During Cryopreservation

Osmotic stress occurs throughout the cryopreservation workflow from multiple sources:

- Freezing phase: As extracellular water freezes, solute concentration in the unfrozen fraction increases, creating hypertonic conditions that draw water out of cells, potentially causing excessive dehydration.

- CPA addition: Introduction of cryoprotectants like DMSO creates a strong osmotic gradient, causing rapid water efflux and cell shrinkage if not properly controlled.

- Thawing phase: As temperatures rise, melting ice creates hypotonic extracellular conditions, driving water influx and cell swelling.

- CPA removal: Dilution or removal of cryoprotectants post-thaw can cause massive water influx and potential membrane rupture if not performed gradually with proper osmotic buffers.

How does osmotic stress manifest in cellular damage?

Osmotic stress during cryopreservation causes both immediate and delayed cellular damage:

- Membrane tension from rapid volume changes can exceed elastic limits, causing rupture

- Activation of mechanosensitive ion channels disrupting electrochemical gradients

- Cytoskeletal disorganization and disruption of organelle positioning

- Generation of reactive oxygen species (ROS) leading to oxidative damage

- DNA damage and cell cycle arrest, as documented in human bone mesenchymal stem cells [10]

Table 1: Documented Cellular Damage from DMSO Cryopreservation

| Damage Type | Affected Cellular Component | Functional Consequences | Reference |

|---|---|---|---|

| Apoptosis | Membrane integrity & caspase activation | 10-15% immediate post-thaw cell death | [10] |

| Genetic Damage | DNA integrity | 3.8x increase in DNA damage/repair markers | [10] |

| Cell Cycle Disruption | Cell cycle checkpoints | G0/G1 phase arrest | [10] |

| Oxidative Stress | Redox homeostasis | Significantly increased ROS levels | [10] |

| Functional Impairment | Differentiation capacity | Reduced adipogenic & osteogenic potential | [10] |

Troubleshooting Common CPA Challenges

How can researchers mitigate DMSO toxicity while maintaining cryoprotective efficacy?

Strategies to balance efficacy and toxicity include:

- Concentration reduction: Hydrogel microencapsulation enables effective cryopreservation of mesenchymal stem cells with as low as 2.5% DMSO while sustaining viability above the 70% clinical threshold [11].

- Combination approaches: Using DMSO with non-toxic additives like trehalose, ectoine, or betaine allows reduction of DMSO concentration while maintaining protection [12].

- Controlled-rate freezing: Precision freezing protocols improve outcomes at lower DMSO concentrations by optimizing cooling kinetics [13].

- Post-thaw processing: Effective DMSO removal methods including washing, density gradient separation, or bead-based depletion improve post-thaw recovery [5].

What are the key considerations for optimizing freezing and thawing rates?

Optimal thermal protocols must balance competing damage mechanisms:

- Slow cooling rates (<1°C/min) minimize intracellular ice formation but increase exposure to solute effects and osmotic stress

- Rapid cooling rates (>50°C/min) minimize solution effects but risk lethal intracellular ice

- Thawing rates significantly impact recovery; rapid thawing (45°C/min or higher) typically provides best outcomes by minimizing devitrification and recrystallization [13]

- Container-specific optimization is essential as vial, bag, and straw configurations have distinct thermal transfer properties

Table 2: Quantitative Effects of DMSO Concentration on Stem Cell Viability

| DMSO Concentration (vol%) | Post-thaw Viability | Key Observations | Reference |

|---|---|---|---|

| 0% | Below clinical threshold | Insufficient cryoprotection | [11] |

| 1.0% | Below 70% | Below clinical minimum requirement | [11] |

| 1.5-3% | Viable | Threshold where cryoprotective effects diminish | [9] [11] |

| 2.5% | ~70% | Minimum clinical threshold with microencapsulation | [11] |

| 5% | Variable | Intermediate efficacy | [11] |

| 10% | High viability | Significant toxicity concerns: DNA damage, ROS, functional impairment | [11] [10] |

Experimental Protocols for DMSO Optimization

Protocol: Evaluating DMSO Concentration Effects with Hydrogel Microencapsulation

This protocol enables systematic testing of low-dose DMSO cryopreservation for sensitive cell types [11]:

Cell Preparation:

- Culture human umbilical cord mesenchymal stem cells (hUC-MSCs) to 80-90% confluence in complete DMEM/F12 medium with 10% FBS

- Harvest using standard trypsinization and centrifugation

Hydrogel Microencapsulation:

- Prepare core solution: 0.68g mannitol + 0.15g hydroxypropyl methylcellulose in sterile water

- Prepare shell solution: 0.46g mannitol + 0.2g sodium alginate in sterile water

- Resuspend cell pellet in core solution at appropriate density

- Use high-voltage electrostatic coaxial spraying device with:

- Core solution flow rate: 25 μL/min

- Shell solution flow rate: 75 μL/min

- Voltage: 6 kV

- Collect microcapsules in calcium chloride solution for crosslinking

DMSO Exposure and Cryopreservation:

- Prepare cryomedium with DMSO concentrations: 0%, 1.0%, 2.5%, 5.0%, 10.0% (v/v)

- Exchange culture medium with respective cryomedium

- Implement controlled-rate freezing: 1°C/min to -80°C

- Transfer to liquid nitrogen for long-term storage

Post-thaw Analysis:

- Rapid thaw in 37°C water bath

- Assess viability via flow cytometry with Annexin V/PI staining

- Evaluate phenotype retention (CD markers)

- Test differentiation potential (osteogenic/adipogenic induction)

- Measure stemness gene expression (Nanog, Oct4, Sox2)

Protocol: Assessing DNA Damage and Functional Integrity Post-Cryopreservation

Comprehensive safety assessment for therapeutic cell applications [10]:

Cell Culture and Cryopreservation:

- Culture human bone mesenchymal stem cells (hBMSCs) in α-MEM with 10% FBS

- Use passages 3-6 for experiments

- Cryopreserve in standard medium with 10% DMSO using slow cooling

- Store in liquid nitrogen vapor phase

Viability and Apoptosis Assessment:

- Perform AO/PI staining immediately post-thaw

- Calculate viability: (live cells/total cells) × 100%

- Assess apoptosis using Annexin V-FITC/PI flow cytometry

- Include fresh cells as control

DNA Damage Evaluation:

- Culture post-thaw cells for 48 hours

- Fix and stain for γH2AX foci (DNA damage marker)

- Quantify foci per nucleus compared to fresh controls

- Calculate DNA damage ratio: (foci in frozen-thawed)/(foci in fresh)

Cell Cycle Analysis:

- Culture post-thaw cells for 24 hours

- Fix and stain with propidium iodide

- Analyze DNA content by flow cytometry

- Compare cell cycle distribution with fresh controls

Functional Capacity Tests:

- Induce osteogenic and adipogenic differentiation

- Analyze lineage-specific gene expression (Runx2, PPARγ)

- Evaluate migration capacity via transwell assays

- Stain F-actin to assess cytoskeletal organization

Emerging Alternatives and Advanced Solutions

What DMSO-free strategies show promise for stem cell cryopreservation?

Several innovative approaches are advancing toward clinical application:

- Hydrogel microencapsulation: Alginate-based hydrogels provide physical protection and enable radical DMSO reduction to 2.5% while maintaining viability above clinical thresholds and preserving differentiation potential [11].

- Deep Eutectic Solvents (DES): Choline chloride-glycerol mixtures show promising cryoprotection with minimal toxicity, achieving platelet recovery of 88.2% in DMSO-free protocols [14].

- DNA frameworks: Nanoscale DNA structures functionalized with cholesterol provide membrane-targeted cryoprotection, inhibit ice growth, and undergo biodegradation post-thaw to avoid toxicity concerns [15].

- Intracellular trehalose delivery: Using electroporation, nanoparticles, or extended incubation to load non-penetrating sugars provides cryoprotection without chemical toxicity [12].

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagents for DMSO and Osmotic Stress Research

| Reagent/Category | Specific Examples | Research Application | Mechanistic Role |

|---|---|---|---|

| Penetrating CPAs | DMSO, Glycerol, Ethylene Glycol | Standard cryopreservation protocols | Colligative freezing point depression, intracellular penetration |

| Non-penetrating CPAs | Sucrose, Trehalose, Raffinose | Osmotic buffering, vitrification | Extracellular stabilization, glass formation |

| Osmolytes | Ectoine, Hydroxyectoine, Betaine | Osmotic stress protection | Membrane and protein stabilization |

| Hydrogel Materials | Sodium Alginate, Calcium Chloride | Microencapsulation protocols | Physical barrier, 3D microenvironment |

| Membrane Modulators | Cholesterol-DNA Frameworks | Advanced nanomaterial approaches | Membrane stabilization, ice growth inhibition |

| Deep Eutectic Solvents | Choline Chloride-Glycerol | DMSO-free cryopreservation | Hydrogen-bond networks, membrane protection |

| Viability Indicators | AO/PI, Annexin V-FITC, LDH assays | Post-thaw quality assessment | Membrane integrity, apoptosis detection |

| Damage Markers | γH2AX, CD62P, CD63, ROS probes | Cellular stress and damage quantification | DNA damage, activation, oxidative stress |

Frequently Asked Questions

What is the minimum effective DMSO concentration for stem cell cryopreservation?

The minimum effective DMSO concentration depends on cell type and preservation strategy. For mesenchymal stem cells, 2.5% DMSO combined with hydrogel microencapsulation can maintain viability above the 70% clinical threshold [11]. However, concentrations below 2% typically show diminished cryoprotective effects, marking a critical threshold [9]. The optimal concentration balances sufficient ice inhibition with acceptable toxicity levels for your specific application.

How does DMSO cause DNA damage in cryopreserved cells?

DMSO-induced DNA damage occurs through both direct and indirect mechanisms. Research on human bone mesenchymal stem cells reveals approximately 3.8-fold increase in DNA damage/repair markers post-thaw, with DMSO contributing to:

- Reactive oxygen species (ROS) generation causing oxidative DNA lesions

- Cell cycle disruption leading to G0/G1 arrest and impaired DNA repair

- Direct interactions with nucleic acids and associated proteins

- Activation of apoptotic pathways that involve DNA fragmentation [10]

What are the advantages of controlled-rate freezing versus passive freezing?

Controlled-rate freezing provides significant advantages for reproducibility and cell quality:

- Parameter control: Precisely manage cooling rate before/after nucleation, nucleation temperature, and final sample temperature

- Process documentation: Automated recording of critical process parameters

- Consistency: Minimize batch-to-batch variability in post-thaw recovery

- Optimization capability: Systematically test freezing profiles for sensitive cell types

- Regulatory compliance: Better alignment with GMP requirements for therapeutic applications [13]

Industry surveys indicate 87% of respondents use controlled-rate freezing for cell-based products, with particularly high adoption in late-stage clinical development [13].

Technical Support & Troubleshooting Center

This technical support center is designed to assist researchers in navigating the specific vulnerabilities of induced pluripotent stem cells (iPSCs), with a focus on improving post-thaw recovery and viability. The following guides and FAQs address common experimental challenges, providing practical solutions grounded in current research.

Frequently Asked Questions (FAQs)

Q1: Why are iPSCs particularly vulnerable to cryopreservation compared to other cell types? iPSCs possess a unique biological sensitivity to environmental and handling conditions, making them especially vulnerable to losses in viability and function during freezing and thawing. They are more susceptible to cryopreservation-induced stresses like intracellular ice formation, osmotic shock, and dehydration than many conventional cell types [16] [17]. Their large surface area-to-volume ratio also contributes to this sensitivity [17].

Q2: My post-thaw iPSC viability is low. What are the first parameters I should check? First, verify your freezing rate. A controlled rate of -1°C to -3°C per minute is often optimal for iPSCs; deviations can drastically reduce survival [17]. Next, check the concentration of DMSO in your cryoprotectant; consider testing formulations with lower DMSO (e.g., 5%) supplemented with ice recrystallization inhibitors (IRIs) to mitigate toxicity [18]. Finally, ensure you are using high-quality, GMP-grade reagents to avoid introducing variability [16].

Q3: How can I reduce the risk of contamination during the post-thaw QC sampling process? To maintain aseptic conditions, minimize direct product contact by using container closure strategies and sampling through sterile connectors. Process engineering solutions, such as integrated sampling ports in cryo-containers or automated thaw-and-transfer systems, can further reduce manual handling and standardize sampling across sites [16].

Q4: What is a risk-based approach to post-thaw quality control (QC)? A risk-based QC panel focuses on minimal, essential criteria to verify product integrity without excessive manipulation. This typically includes cell count, viability, and critical quality markers associated with potency or pluripotency. Working with regulatory agencies to align on a scientifically justified panel balances robust verification with the need to protect the final drug product from contamination or loss [16].

Q5: When should I consider automating my thawing and downstream processes? Automation becomes critical when seeking enhanced batch consistency, process closure, and contamination control. While manual methods offer flexibility for early-phase research, automated systems standardize critical steps like thawing rates and wash protocols, locking in consistent post-thaw recovery. A hybrid strategy, automating high-risk steps like fill-finish first, can be a practical approach for many developers [16].

Troubleshooting Guides

Problem: Poor Post-Thaw Cell Recovery and Viability

Potential Causes and Solutions:

Suboptimal Freezing Rate

- Cause: Uncontrolled or incorrect cooling rates lead to destructive intracellular ice crystal formation or excessive cell dehydration [17].

- Solution: Use a controlled-rate freezer. Research indicates that a cooling rate within -0.3°C to -1.8°C/min is optimal for many pluripotent stem cells. A rate of -1°C/min is frequently used successfully for iPSCs [17].

Cryoprotectant-Associated Toxicity

- Cause: High concentrations of DMSO (e.g., 10%) are cytotoxic and can damage cells [18] [17].

- Solution: Explore alternative cryoprotectant formulations. Recent studies show that solutions containing 15 mM ice recrystallization inhibitors (IRIs) in 5% DMSO can be an efficient cryoprotective solution, reducing DMSO-associated toxicities while maintaining post-thaw recovery, viability, and pluripotency [18].

Improper Handling During Thawing

- Cause: Osmotic shock during the removal of cryoprotectants [17].

- Solution: During thawing, add pre-warmed complete medium to the cell suspension drop-wise (approximately one drop per second) while gently swirling the tube. This gradual dilution prevents rapid osmotic changes that can damage fragile cells [19].

Problem: Excessive Differentiation in Cultures After Thawing

Potential Causes and Solutions:

Poor Initial Culture Health

Over-manipulation Post-Thaw

Incorrect Seeding Density

Data & Protocol Summaries

Table 1: Comparison of Cryoprotectant Solutions for iPSCs

| Solution Formulation | Post-Thaw Viability | Pluripotency Maintenance | Key Advantages | Key Disadvantages |

|---|---|---|---|---|

| 10% DMSO (Standard Solution) | Variable, can be suboptimal [18] | Maintained, but with risk of toxicity | Widely used, simple formulation | High DMSO toxicity, batch-to-batch variability [16] |

| 5% DMSO + 15 mM IRIs (Advanced Formulation) | High [18] | Maintained, with reduced transcriptomic changes [18] | Reduces DMSO toxicity, improves consistency, robust transcriptomic profile [18] | Requires sourcing of specialized IRIs |

| CryoStor CS10 (Commercial Solution) | High (used as a benchmark in studies [18]) | Maintained | Commercially available, GMP-manufactured | Proprietary formulation, cost |

Table 2: Post-Thaw Recovery Timeline Under Optimized vs. Non-optimized Conditions

| Parameter | Optimized Protocol | Non-Optimized Protocol |

|---|---|---|

| Time to Ready for Experiments | 4-7 days after thawing and seeding [17] | Up to 2-3 weeks [17] |

| Key Influencing Factors | Controlled freezing rate, advanced cryoprotectants, proper handling to prevent osmotic shock [18] [17] | Uncontrolled freezing, high DMSO toxicity, osmotic shock during thawing [17] |

| Experimental Complications | Minimal, predictable timeline [17] | Significant delays, unpredictable cell behavior, resource waste [17] |

Experimental Protocol: Assessing Post-Thaw Cell Quality

A comprehensive assessment of post-thaw iPSCs goes beyond simple viability. The following methodology outlines key steps for evaluating recovery and function.

1. Thawing and Plating:

- Quickly thaw cryovials in a 37°C water bath until only a small ice crystal remains [17].

- Transfer the contents to a tube and slowly add pre-warmed complete medium drop-wise to dilute the cryoprotectant [19].

- Centrifuge the cell suspension to pellet the cells, resuspend in fresh culture medium, and plate onto Matrigel-coated plates.

2. Viability and Recovery Assessment:

- Timepoint: 24 hours post-thaw.

- Method: Perform a cell count using an automated cell counter (e.g., Countess II) with Trypan Blue exclusion to assess immediate post-thaw viability [21].

3. Pluripotency and Phenotype Verification:

- Timepoint: 3-5 days post-thaw, upon reaching confluency.

- Method: Immunocytochemistry (ICC) or flow cytometry for key markers.

- Neurons (if differentiated): Antibodies against NeuN and βIII-tubulin (Tuj1) [21].

- Astrocytes (if differentiated): Antibodies against GFAP and CD44 [21].

- Microglia (if differentiated): Antibodies against IBA1 and P2RY12 [21].

- Undifferentiated iPSCs: Staining for pluripotency markers like OCT4, SOX2, and NANOG is recommended to confirm maintenance of pluripotent state.

- Success Criterion: Differentiation efficiency or pluripotency marker expression should exceed 95% with no evidence of a contaminating proliferative population (assessed with Ki67 staining) [21].

The Scientist's Toolkit: Essential Research Reagents

| Item | Function | Example & Notes |

|---|---|---|

| ROCK Inhibitor (Y-27632) | Improves single-cell survival by inhibiting apoptosis; used during passaging and post-thaw plating [21] [19]. | Add to medium at 10 µM for 24 hours after thawing [19]. |

| Ice Recrystallization Inhibitors (IRIs) | Small molecules that inhibit the growth of ice crystals during thawing, reducing cell damage and enabling lower DMSO concentrations [18]. | e.g., carbohydrate-based IRIs; used at 15 mM in 5% DMSO [18]. |

| GMP-Grade Matrigel/VTN-N | Defined extracellular matrix substrate for feeder-free culture, providing a consistent surface for cell attachment and growth [19]. | Essential for scalable and compliant manufacturing; ensures consistency [16] [19]. |

| mTeSR or Essential 8 Medium | Chemically defined, xeno-free culture media optimized for the maintenance and growth of pluripotent stem cells [21] [19]. | Supports robust cell growth; Essential 8 allows transition from other media systems [19]. |

| Annexin V Apoptosis Assay | Sensitive assay to detect early-stage apoptosis (phosphatidylserine exposure), which can reveal subtle cell stress not detected by Trypan Blue [16]. | Useful for uncovering delayed apoptosis or loss of functionality 24-72 hours post-thaw [16]. |

Experimental Workflow Visualization

The following diagram illustrates the critical stages of the iPSC thawing and recovery process, highlighting key vulnerabilities and intervention points.

The three-zone freezing model represents a sophisticated approach to cryopreservation that moves beyond constant cooling rates. This model is particularly crucial for sensitive cell types like human induced pluripotent stem cells (hiPSCs), where optimal post-thaw viability is essential for research and clinical applications. The model is founded on the "two-factor theory" of cryoinjury, which posits that cells are primarily damaged by two competing factors: intracellular ice formation and cell dehydration [22]. The three-zone framework strategically balances these competing risks by applying specific cooling rates at different temperature ranges to maximize cell survival [23] [22].

For hiPSCs, which are more vulnerable to intracellular ice formation than many other cell types, strict control of the cooling rate is particularly critical [23]. Research by Hayashi et al. suggests that a constant cooling rate does not yield the best cell survival outcomes. Instead, their model-based assessment of 16,206 temperature profiles demonstrated that a specific sequence of cooling rates applied across three distinct temperature zones produces superior results [22]. This approach forms the foundation of modern, optimized cryopreservation protocols for regenerative medicine applications.

Detailed Zone Specifications and Protocols

The Three Zones: Mechanisms and Parameters

The three-zone freezing model divides the cryopreservation process into distinct phases, each addressing specific physicochemical challenges. The table below summarizes the key characteristics of each zone:

Table 1: Specifications of the Three-Zone Freezing Model

| Zone Name | Temperature Range | Cooling Rate | Primary Cellular Process | Main Risk to Mitigate |

|---|---|---|---|---|

| Dehydration Zone | From initial temperature to below freezing | Fast cooling | Extracellular ice formation, cellular dehydration | Excessive dehydration and solute effects |

| Nucleation Zone (Intracellular Ice Formation Zone) | Critical temperature range where intracellular ice forms | Slow cooling | Intracellular ice nucleation | Intracellular ice crystal formation |

| Further Cooling Zone | From nucleation completion to final storage temperature | Fast cooling | Stabilization of frozen state | Re-crystallization and mechanical damage |

Experimental Protocol for Three-Zone Freezing

Materials Required:

- STEM-CELLBANKER GMP grade or similar cryopreservation solution [22]

- Programmable freezing system or appropriate cryocontainers

- Cryogenic vials

- hiPSCs in logarithmic growth phase [23]

Methodology:

- Cell Preparation: Harvest hiPSCs during the logarithmic growth phase to ensure optimal recovery post-thaw [23]. Prepare cell suspension in appropriate cryopreservation solution containing cryoprotectants such as DMSO.

Dehydration Zone Protocol:

- Transfer cryovials containing cell suspension to the freezing apparatus.

- Apply rapid cooling from initial temperature to below freezing point.

- This rapid initial cooling minimizes prolonged cellular dehydration.

Nucleation Zone Protocol:

Further Cooling Zone Protocol:

- Once through the nucleation danger zone, increase cooling rate again.

- Rapidly cool cells to the final storage temperature (typically -80°C or below).

- Transfer to long-term storage in liquid nitrogen vapor phase or -150°C freezers [23].

Storage Considerations:

- Maintain storage below -123°C (extracellular glass transition temperature of DMSO) to prevent stressful thermal events [23].

- Avoid temperature fluctuations during storage to prevent ice crystal growth.

Troubleshooting Common Issues

Frequently Asked Questions

Table 2: Troubleshooting Common Cryopreservation Problems

| Problem | Potential Causes | Solutions | Preventive Measures |

|---|---|---|---|

| Poor post-thaw viability | Suboptimal cooling rate through nucleation zone; improper pre-freeze culture conditions | Test different cooling rates in nucleation zone between -0.3 to -1.8°C/min; ensure cells are in logarithmic growth phase before freezing [23] | Standardize pre-freeze culture protocols; validate cooling rates for specific cell line |

| High intracellular ice formation | Cooling too rapidly through nucleation zone; inappropriate cryoprotectant concentration | Slow cooling rate through nucleation zone; verify cryoprotectant concentration and permeability [23] [22] | Implement controlled-rate freezing equipment; optimize cryoprotectant addition/removal steps |

| Excessive cell dehydration | Cooling too slowly through dehydration zone; overexposure to hypertonic cryoprotectant | Increase cooling rate in dehydration zone; reduce incubation time in cryoprotectant before freezing [22] | Optimize timing of cryoprotectant addition; implement fast-slow-fast cooling pattern |

| Variable recovery between vials | Inconsistent temperature profiles during freezing; improper storage conditions | Validate temperature uniformity in freezing system; ensure consistent fill volume in cryovials [23] | Use controlled-rate freezing equipment; monitor storage temperature stability |

Q1: Why is the logarithmic growth phase important before freezing hiPSCs?

Cells in the logarithmic growth phase are physiologically more uniform and robust, exhibiting better recovery post-thaw compared to cells from stationary or decline phases. This ensures higher viability and more consistent experimental results [23].

Q2: How can I determine the optimal cooling rate for my specific cell type in the nucleation zone?

The optimal cooling rate is cell type-specific. For hiPSCs, research indicates that rates between -0.3 and -1.8 °C/min are generally effective [23]. However, systematic experimentation with different rates while monitoring post-thaw viability is recommended for specific cell lines. Computational modeling approaches can also help predict optimal parameters [22].

Q3: What is the impact of cryoprotectant choice on the three-zone model?

Cryoprotectants like DMSO reduce ice crystal formation by penetrating cells and altering ice formation dynamics. The hypertonic nature of cryoprotectant solutions (approximately 1.4 osm/L for 10% DMSO) causes initial cellular dehydration, which interacts with the dehydration zone processes. Different cryoprotectants may require adjustments to zone cooling rates [23].

Q4: How long should the acclimation period be after thawing, and why is it important?

Research on mesenchymal stem cells demonstrates that a 24-hour acclimation period post-thaw allows cells to regain functional potency. Immediately after thawing (freshly thawed cells), various aspects of cell characteristics and function are deleteriously affected by cryopreservation. The acclimation period 'reactivates' thawed cells, enabling recovery of diminished stem-cell function [24].

Research Reagent Solutions

Table 3: Essential Materials for Three-Zone Freezing Experiments

| Reagent/Equipment | Function | Example Products | Application Notes |

|---|---|---|---|

| Controlled-Rate Freezer | Implements precise temperature profiles across the three zones | Programmable freezing systems; FZ-2000 direct-contact freezer [22] | Essential for consistent application of three-zone protocol |

| Cryopreservation Media | Provides cryoprotection and osmotic balance | STEM-CELLBANKER GMP grade [22] [25] | Contains DMSO and other cryoprotectants; specific formulations may enhance recovery |

| Cryogenic Vials | Contain cell suspension during freezing and storage | Standard 2.0 mL cryovials [26] | Consistent vial material and fill volumes improve temperature uniformity |

| Temperature Monitoring System | Validates temperature profiles during freezing | T-type thermocouples [26] | Critical for protocol validation and troubleshooting |

| DMSO (Dimethyl Sulfoxide) | Penetrating cryoprotectant agent | Various GMP-grade sources | Reduces ice crystal formation; typically used at 10% concentration [23] |

| Post-Thaw Recovery Media | Supports cell recovery after thawing | Media supplemented with Y-27632 (10 μM) [22] | Enhances survival of sensitive stem cells during critical post-thaw period |

Visualizing the Three-Zone Model

The following diagram illustrates the temperature profile and cellular processes in the three-zone freezing model:

Figure 1: Three-Zone Freezing Model Workflow. This diagram illustrates the sequential temperature zones and primary cellular processes during controlled-rate cryopreservation.

Advanced Applications and Computational Modeling

The three-zone model has evolved beyond empirical optimization to incorporate sophisticated computational approaches. Recent research has demonstrated the effectiveness of Computational Fluid Dynamics (CFD) models for designing continuous freezing processes for hiPSCs [27] [26]. These models combine single-cell freezing mechanisms with system-level heat transfer calculations to predict cell survival rates under various process parameters [27].

For advanced applications such as the cryopreservation of 3D structures like cell sheets or microcardiac spheroids, the three-zone principle requires adaptation. Research shows that freezing 100-200 μm diameter microcardiac spheroids using optimized protocols can maintain approximately 80% viability after 6 months of cryopreservation in liquid nitrogen [28]. The integrity of cell-cell contacts in these 3D structures contributes significantly to their cryoresistance.

The following diagram illustrates the experimental workflow for implementing and validating the three-zone freezing model:

Figure 2: Experimental Workflow for Three-Zone Freezing Protocol. This diagram shows the implementation process from cell preparation to post-thaw analysis, including computational modeling feedback for protocol optimization.

These computational approaches enable researchers to scale up freezing processes significantly. One study demonstrated that properly designed continuous freezing processes could be scaled to up to 170-fold compared to currently used equipment for hiPSC freezing while maintaining average cell survival rates above 0.90 [26]. This scalability is essential for the clinical translation and commercialization of stem cell-based therapies.

The three-zone freezing model represents a significant advancement in cryopreservation science, moving beyond empirical approaches to a mechanistic, computationally-enhanced framework. By understanding and optimizing the processes in each zone, researchers can significantly improve post-thaw recovery of valuable cell resources, accelerating progress in regenerative medicine and drug development.

Frequently Asked Questions

Q1: Why is the logarithmic growth phase so critical for cryopreserving stem cells? Freezing cells during the log phase ensures they are at their most robust state of metabolic activity and proliferation. Cells in this phase are healthiest and most resilient, which allows them to better withstand the significant stresses of the freezing and thawing process. This leads to higher post-thaw viability and faster recovery of a stable, proliferative culture, typically within 4–7 days. In contrast, freezing cells from the stationary or death phases can result in poor recovery and extended culture times of up to 2–3 weeks [23] [29].

Q2: What are the consequences of cryopreserving a contaminated cell culture? Cryopreservation does not eliminate contamination; it preserves it. Upon thawing, microbial contaminants will proliferate, competing with your cells for nutrients and secreting toxic metabolites. This compromises cell health, viability, and experimental results, and risks spreading the contamination to other cell lines in your laboratory. Microbial contamination can also increase cell death, leading to a higher burden of cellular debris in the cryopreserved vial, which can further impair the recovery of healthy cells [23] [30] [29].

Q3: How can I visually identify the logarithmic growth phase in my adherent stem cell cultures? For adherent cultures, the log phase is characterized by active cell division, high confluency (typically between 70% to 90%), and healthy, undifferentiated morphology. Cells should be actively proliferating but not yet fully confluent. You should observe a rapid drop in media pH (yellowing of phenol red) due to high metabolic activity, requiring frequent medium changes. A drop in pH of more than 0.1–0.2 units often indicates a high cell concentration and active growth [31].

Q4: Does pre-freeze processing, like switching from aggregates to single cells, affect recovery? Yes, the passaging method significantly impacts post-thaw recovery. The choice involves a trade-off:

- Freezing as Aggregates: This method preserves cell-cell contacts, which can support survival. Recovery can be faster as cells are already in their natural clustered state. However, variable aggregate size can lead to inconsistent penetration of cryoprotectant, causing vial-to-vial variability in viability [23].

- Freezing as Single Cells: This allows for precise cell counting and more consistent seeding densities, leading to more standardized recovery. The downside is that single cells may be more vulnerable to cryo-damage and require more time to re-form aggregates after thawing [23]. The optimal method depends on your specific cell line and experimental requirements.

Troubleshooting Guides

Problem: Low Post-Thaw Viability and Slow Proliferation

Potential Causes and Solutions:

Cause 1: Cells were frozen from a non-logarithmic growth phase.

Cause 2: Undetected microbial contamination (e.g., Mycoplasma) compromising cell health pre-freeze.

- Solution: Integrate routine mycoplasma testing into your workflow before freezing. Use PCR-based detection kits. Always wear a face mask during freezing procedures to prevent oral microbial transfer (e.g., Mycoplasma orale) into cryovials [23].

Cause 3: Suboptimal freezing rate causing ice crystal formation.

- Solution: Use a controlled-rate freezer or an isopropanol freezing chamber (e.g., "Mr. Frosty") placed in a -80°C freezer to ensure a consistent cooling rate of approximately -1°C per minute. This slow freezing is vital for preventing lethal intracellular ice formation in sensitive stem cells [23] [32] [29].

The logic for investigating poor post-thaw recovery, focusing on the pre-freeze cell state, can be summarized as follows:

Problem: Inconsistent Recovery Between Frozen Vials

Potential Causes and Solutions:

Cause 1: Inconsistent cell passaging and aggregation before freezing.

Cause 2: Fluctuations in incubator temperature, CO2, or humidity affecting pre-freeze cell health.

- Solution: Regularly calibrate and monitor incubator conditions. Ensure temperature is stable at 37°C and CO2 is appropriate for your medium's bicarbonate buffer (typically 5%) [31].

Table 1: Impact of Cell Growth Phase on Post-Thaw Recovery

| Growth Phase | Key Characteristics | Impact on Post-Thaw Recovery | Recommended Action |

|---|---|---|---|

| Lag Phase | Cells are adapting, not dividing; metabolic preparation [33]. | Slow and poor recovery; cells are not at peak resilience. | Do not freeze. Wait for exponential growth. |

| Log (Exponential) Phase | Active cell division; high metabolic activity; rapid nutrient consumption [33] [31]. | Optimal recovery; high viability; rapid proliferation post-thaw (4-7 days) [23] [29]. | Ideal for freezing. Harvest at 70-90% confluency. |

| Stationary Phase | Growth plateaus due to contact inhibition or nutrient depletion; stress responses may begin [33] [31]. | Suboptimal recovery; reduced viability; potential for increased differentiation or apoptosis. | Avoid freezing. Subculture to re-establish log phase growth. |

| Death Phase | Widespread cell death and lysis; accumulation of debris [33]. | Very poor recovery and viability; culture is often unrecoverable. | Do not freeze. Discard and thaw a new vial. |

Table 2: Consequences and Detection of Common Contaminations

| Contamination Type | Pre-freeze Indicators | Impact on Cryopreservation & Post-Thaw Recovery |

|---|---|---|

| Mycoplasma | Often subtle; possible granularity in cytoplasm, slight changes in growth rate [23] [34]. | Compromised cell health leads to low viability. Contamination persists post-thaw, invalidating experiments and risking cross-contamination [23]. |

| Bacterial | Turbid medium; rapid pH shift to yellow (acidic); possible visible films or spots [29] [35]. | High cell death; toxicity from bacterial wastes; likely complete culture loss upon thawing. |

| Fungal | Fuzzy, filamentous, or spherical particles in medium; resistant to common antibiotics [34]. | Overgrowth post-thaw, consuming nutrients and secreting toxins, leading to culture loss. |

Experimental Protocols

Protocol 1: Standardized Cryopreservation of Stem Cells in Logarithmic Growth Phase

Objective: To freeze high-quality stem cell stocks with maximum post-thaw viability by ensuring cells are harvested during the logarithmic growth phase.

Materials:

- Log-phase stem cell culture (>90% viability, 70-90% confluent) [29]

- Pre-warmed complete growth medium

- Cryoprotective agent (e.g., DMSO-based solution like CryoStor CS10 or mFreSR) [29]

- Sterile cryogenic vials

- Controlled-rate freezing apparatus (e.g., isopropanol chamber like "Mr. Frosty" or programmable freezer)

Method:

- Confirm Log Phase: Visually inspect cultures under a microscope. Cells should be sub-confluent (70-90%), displaying healthy, undifferentiated morphology, and the medium should be rapidly acidifying (if using phenol red) [31].

- Harvest Cells: Detach adherent cells gently using a suitable dissociation reagent. For cells frozen as aggregates, use a method that yields clumps of uniform size [23].

- Prepare Cell Suspension: Centrifuge the cell suspension, aspirate the supernatant, and resuspend the cell pellet in an appropriate amount of cold freezing medium to achieve a final concentration of ~1x10^6 cells/mL (adjust based on cell type) [32] [29] [35].

- Aliquot: Dispense the cell suspension into cryovials. Gently mix the suspension frequently to maintain homogeneity [32].

- Controlled-Rate Freezing: Place cryovials in a pre-cooled isopropanol freezing chamber and immediately transfer to a -80°C freezer for 24 hours. This achieves a cooling rate of approximately -1°C/min, which is critical for cell survival [23] [32] [29].

- Long-Term Storage: After 24 hours, quickly transfer the vials to a liquid nitrogen tank for long-term storage in the vapor phase (-135°C to -196°C) [23] [29].

Protocol 2: Pre-freeze Contamination Screening Workflow

Objective: To routinely screen stem cell cultures for microbial contamination prior to cryopreservation.

Materials:

- Conditioned medium from the stem cell culture to be frozen

- Mycoplasma detection kit (PCR-based)

- Bacterial/fungal culture media (e.g., blood agar plates)

- Microscope

Method:

- Visual Inspection: Examine the culture medium for unexplained turbidity or a sudden, drastic color change. Check the cells for any unusual morphology or debris under a microscope [35].

- Mycoplasma Testing: Collect conditioned medium and perform a PCR-based mycoplasma test according to the manufacturer's instructions. This is the most reliable method for detecting this common and invisible contaminant [23] [34].

- Microbial Culture (Optional but Recommended): Inoculate a small sample of conditioned medium into sterile broth or onto agar plates. Incubate separately at 37°C and at room temperature for several days and observe for microbial growth [34].

- Decision Point: Only proceed with cryopreservation if all contamination tests return negative results. If contamination is detected, the culture must be discarded, and the lab space and equipment decontaminated [29].

The workflow for ensuring a contamination-free, log-phase culture ready for cryopreservation is outlined below:

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagents for Pre-freeze Quality Control

| Reagent / Material | Function | Example Products |

|---|---|---|

| Defined Cryomedium | Provides a protective, consistent environment during freezing; contains cryoprotectants like DMSO to prevent ice crystal formation. | CryoStor [29], Synth-a-Freeze [32] |

| Controlled-Rate Freezer | Ensures a consistent, optimal cooling rate (approx. -1°C/min) to minimize cryo-damage from ice crystals. | "Mr. Frosty" [32], Corning CoolCell [29], programmable freezers |

| Mycoplasma Detection Kit | Essential for detecting this common, invisible cell culture contaminant that compromises pre-freeze cell health. | PCR-based detection kits [23] [34] |

| Cell Dissociation Reagents | For gentle and effective harvesting of adherent cells, either as single cells or uniform aggregates. | Trypsin-EDTA, TrypLE Express [32] |

| Serum-Free Media | Provides a defined, consistent culture environment free of unknown variables present in serum, supporting robust log-phase growth. | mTeSR [29] |

From Protocol to Practice: Advanced Freezing, Thawing, and Processing Techniques

Technical Troubleshooting Guides

Troubleshooting Poor Post-Thaw Cell Viability

Problem: Low cell viability recovery after thawing cryopreserved samples.

Possible Causes and Solutions:

Cause: Suboptimal freezing rate

- For Controlled-Rate Freezers (CRF): Validate and adjust the cooling profile. Different cell types require specific cooling rates; for example, human iPSCs often recover best at rates between -1°C/min and -3°C/min [23].

- For Passive Freezing: Ensure consistent conditions in the -80°C mechanical freezer. Use insulating devices like isopropanol (IPA) containers or styrofoam to help achieve a cooling rate of approximately 1-2°C/min, which is critical for HPCs [36].

Cause: Inadequate cryoprotectant handling

Cause: Osmotic shock during thawing

- Thaw cells rapidly in a 37°C water bath to minimize exposure to toxic cryoprotectant concentrations and avoid osmotic stress. Use controlled-thawing devices to improve reproducibility and minimize contamination risks associated with conventional water baths [13].

Troubleshooting Inconsistent Results Between Batches

Problem: Significant variation in post-thaw viability between different freezing runs.

Possible Causes and Solutions:

Cause: Improper CRF qualification

- Conduct comprehensive freezer qualification that includes temperature mapping across a grid of locations, using different container types, and testing mixed load configurations. Do not rely solely on vendor Factory Acceptance Testing, as it may not represent your specific use case [13].

Cause: Variable sample characteristics

- Freeze cells during the logarithmic growth phase for improved recovery [23].

- For iPSCs, consider the passaging method; freezing as cell aggregates (clumps) can support cell survival but may lead to variability in cryoprotectant penetration, while single-cell freezing allows for better quantification but may require more recovery time [23].

Cause: Lack of process monitoring

- Implement freeze curves as part of process monitoring and manufacturing controls. Establish action or alert limits for curves to identify changes in CRF performance before critical failure occurs [13].

Frequently Asked Questions (FAQs)

Q1: When should I choose controlled-rate freezing over passive freezing for my cell therapy product?

The choice depends on your development stage, cell type, and resources. Survey data indicates that 87% of cell therapy professionals use CRF in their current practice, while passive freezing is predominantly used (86%) for products in early clinical development (up to phase II) [13]. Adopting CRF early can avoid the challenging process of making a significant manufacturing change later. However, for certain cell types like Hematopoietic Progenitor Cells (HPCs), recent evidence suggests passive freezing can be an acceptable alternative, showing comparable engraftment outcomes [36] [38].

Q2: Is the default profile on my controlled-rate freezer sufficient, or do I need to optimize it?

Industry surveys show that 60% of users rely on default CRF profiles, which work for a wide variety of products [13]. However, optimized profiles are often necessary for sensitive or specialized cells, including iPSCs, hepatocytes, cardiomyocytes, and certain immune cells like macrophages and B cells. The need for optimization should be determined case-by-case, considering cell type, cryoprotectant formulation, primary container, and critical quality attributes [13].

Q3: Can I store my cells long-term at -80°C, or do I need liquid nitrogen storage?

For true long-term storage (years), temperatures below -130°C are required where all molecular processes cease [23]. However, recent research demonstrates that hematopoietic stem cells can maintain sufficient viability for durable engraftment even after long-term storage at -80°C (median 868 days in one study) despite a gradual, time-dependent decline in viability of approximately 1.02% per 100 days [39]. For other cell types like Dental Pulp-derived Stem Cells (DPSCs), viability, proliferative capacity, and stemness can be maintained for up to 13 years with proper cryopreservation before storage [40].

Q4: What are the most critical factors for successful thawing of cryopreserved cells?

Successful thawing requires:

- Rapid warming: Established good practice includes a warming rate of 45°C/min, though optimal rates may vary by cell type [13].

- Prevention of osmotic shock: Rapid dilution to minimize DMSO exposure is critical [23].

- Use of controlled-thawing devices: These provide more reproducible results and lower contamination risk compared to conventional water baths [13].

- Proper training of bedside staff: Particularly important for clinical applications where thawing is often poorly regulated [13].

Comparative Data Analysis

Table 1: Direct Comparison of Controlled-Rate vs. Passive Freezing Methods

| Parameter | Controlled-Rate Freezing (CRF) | Passive Freezing (PF) |

|---|---|---|

| Control over process parameters | High - Precise control over cooling rates, nucleation temperature, and final sample temperature [13] | Low - Uncontrolled nucleation and inconsistent cooling rates [36] |

| Initial equipment cost | High - Substantial investment required [41] | Low - Utilizes standard -80°C mechanical freezers [41] |

| Operational complexity | High - Requires specialized expertise for use and optimization [13] | Low - Simple, one-step operation with low technical barrier [13] |

| Batch scalability | Can be a bottleneck for large-scale batch processing [13] | Easier scaling due to simplicity [13] |

| Documentation & compliance | Built-in data logging for traceability and regulatory compliance [41] | Limited monitoring and documentation capabilities [36] |

| Typical cell viability outcomes | Higher TNC viability reported for HPCs (74.2% ± 9.9%) [36] | Slightly lower TNC viability for HPCs (68.4% ± 9.4%) but comparable CD34+ viability [36] |

| Clinical engraftment results | Similar neutrophil (12.4 ± 5.0 days) and platelet engraftment (21.5 ± 9.1 days) for HPCs [36] | Similar neutrophil (15.0 ± 7.7 days) and platelet engraftment (22.3 ± 22.8 days) for HPCs [36] |

Table 2: Research Reagent Solutions for Cryopreservation

| Reagent/Material | Function | Example Applications & Concentrations |

|---|---|---|

| Dimethyl Sulfoxide (DMSO) | Penetrating cryoprotectant that prevents intracellular ice crystal formation [23] | 5-15% concentration in various media; 10% DMSO has osmolarity of ~1.4 osm/L [37] [23] |

| Human Serum Albumin | Protein stabilizer that reduces cryoinjury and membrane damage [37] | Commonly used at 9% concentration in combination with DMSO for HPC cryopreservation [36] |

| Ficoll 70 | Non-penetrating polymer enabling long-term storage at -80°C [23] | Added to freezing solution for iPSC preservation at -80°C for at least one year [23] |

| Cryobags | Primary containers for cryopreservation with integral tubing [37] | Volumes from 50-500 mL; most centers use 2-4 bags per collection [37] |

| Isopropanol (IPA) containers | Passive freezing devices providing approximately -1°C/min cooling rate [41] | Placed in -80°C mechanical freezer for uncontrolled-rate freezing of various cell types [41] |

Experimental Protocols

Protocol 1: Qualification of Controlled-Rate Freezers

Purpose: To ensure CRF performance meets specific use case requirements and regulatory standards.

Methodology:

- Temperature Mapping: Perform full versus empty chamber mapping across a three-dimensional grid of locations to identify hot/cold spots [13].

- Freeze Curve Mapping: Test different container types (vials, bags) in various locations within the chamber [13].

- Mixed Load Validation: Evaluate performance with different sample masses and configurations to define operational limits [13].

- Profile Verification: Confirm that actual temperature profiles match programmed parameters for both default and customized freezing protocols.

Reference Standards: Consult the ISPE Good Practice Guide: Controlled Temperature Chambers 2nd Edition, 2021, for comprehensive guidance [13].

Protocol 2: Viability Assessment Post-Thaw

Purpose: To accurately determine cell recovery and functionality after cryopreservation.

Methodology:

- Viability Staining:

- Functional Assays:

- Senescence Evaluation:

Experimental Workflow and Decision Pathways

Diagram 1: Decision Pathway for Cryopreservation Method Selection. This workflow guides researchers in selecting the appropriate freezing method based on clinical development stage, cell type, and available resources.

Diagram 2: Comprehensive Cryopreservation Experimental Workflow. This diagram outlines the complete experimental protocol from cell preparation through post-thaw assessment, highlighting critical steps for both freezing methods.

Technical Troubleshooting Guide

FAQ: Addressing Common Cryopreservation Challenges

Q: My post-thaw iPSC viability is consistently low. What is the most critical factor I should check?

A: The cooling rate is a primary suspect. Evidence confirms that human iPSCs are particularly vulnerable to intracellular ice formation and require a slow, controlled freezing rate. While a cooling rate of -1°C/min is a frequently used and effective standard for iPSCs, optimal recovery has been demonstrated within the -1°C/min to -3°C/min range [17]. You should verify that your controlled-rate freezer is correctly calibrated and programmed for this specific rate. Furthermore, ensure you are using a cryoprotectant such as DMSO, which penetrates cells to prevent ice crystal formation [42] [17].

Q: I am cryopreserving multiple cell types. Can I use the same cooling rate for all of them?

A: No, a "one-size-fits-all" approach is not optimal. Different cell types have unique biological characteristics, such as membrane permeability and volume, which demand specific cooling rates [43]. For instance, algorithm-driven optimization found that the ideal cooling rate for Jurkat lymphocytes was 10°C/min, while for mesenchymal stem cells (MSCs) it was 1°C/min [44]. Using an incorrect rate can lead to cell death from either intracellular ice formation (if too fast) or excessive dehydration and "solution effects" (if too slow) [45] [17]. The table below summarizes optimal rates for various cell types.

Q: What does the "two-factor hypothesis of cryo-injury" mean for my protocol?

A: This hypothesis explains the inverted 'U'-shaped cell survival curve seen when testing different cooling rates [45]. Injury occurs for two distinct reasons:

- At cooling rates SLOWER than the optimum: Damage is caused by "solution effects," where prolonged exposure to hyperosmotic solute concentrations in the unfrozen extracellular fluid leads to toxic levels of electrolytes and cellular dehydration [45].

- At cooling rates FASTER than the optimum: Damage is caused by lethal intracellular ice formation, as water does not have sufficient time to leave the cell before freezing [45].

Your goal is to find the cooling rate that best balances these two opposing dangers, which is cell-type-specific [45] [44].

Optimized Cooling Rates for Different Cell Types

The following table synthesizes evidence-based cooling rates for a variety of cells, demonstrating that protocol optimization must be cell-type-specific.

Table 1: Evidence-Based Optimal Cooling Rates for Different Cell Types

| Cell Type | Optimal Cooling Rate | Key Evidence and Notes |

|---|---|---|

| Induced Pluripotent Stem Cells (iPSCs) | -1°C/min to -3°C/min | A rate of -1°C/min is frequently used. Testing shows better recovery at -1 to -3°C/min compared to -10°C/min [17]. |

| Mesenchymal Stem Cells (MSCs) | 1°C/min | Identified as optimal via a differential evolution algorithm, using a specific non-DMSO cryoprotectant solution [44]. |

| Jurkat Lymphocytes | 10°C/min | Algorithm-driven optimization determined this faster rate was ideal for this cell line [44]. |

| Lizard Sperm (V. panoptes) | 73°C/min | An intermediate rate was optimal, providing the first direct evidence for the two-factor hypothesis in reptile sperm [45]. |

| Human Oocytes | -0.3°C/min to -30°C, then -50°C/min to -150°C | A multi-step cooling protocol is required due to high susceptibility to ice crystal damage [17]. |

| General Mammalian Cells | 1-3°C/min | A standard range when using cryoprotective agents like DMSO or glycerol [42]. |

The Science of Cryo-Injury: The Two-Factor Hypothesis

The following diagram illustrates the fundamental principle of cryo-injury that underpins the need for cell-type-specific cooling rates. Finding the peak of the curve is the objective of protocol optimization.

Experimental Protocol: Algorithm-Driven Optimization of Cryopreservation Protocols

For researchers looking to move beyond published protocols and systematically optimize conditions for a novel cell type, the following methodology, adapted from [44], provides a powerful, high-throughput framework.

Objective: To simultaneously optimize cryopreservation solution composition and cooling rate for a specific cell type using a Differential Evolution (DE) algorithm, minimizing experimental effort while maximizing post-thaw recovery.

Materials:

- Cell culture of the target cell type.

- Candidate cryoprotectant agents (e.g., trehalose, glycerol, ethylene glycol, sucrose, taurine, ectoine).

- Controlled-rate freezer capable of precise cooling rates (e.g., 0.5°C/min to 10°C/min).

- Multi-well plates for high-throughput testing.

- Viability assay reagents (e.g., flow cytometry with viability dyes).

Methodology:

- Define Parameter Space: Establish discrete concentration levels (e.g., 0-300 mM for solutes) and a range of cooling rates (e.g., 0.5, 1, 3, 5, 10°C/min) to be tested.

- Initialize Algorithm: The DE algorithm randomly generates an initial population of "vectors," where each vector represents a unique combination of solute concentrations and a cooling rate.

- High-Throughput Freezing: Cells are combined with the solution specified by each vector and frozen in a 96-well plate at the designated cooling rate.

- Assess Cell Recovery: Post-thaw live cell recovery is measured for each condition.

- Algorithm Iteration: The experimental recovery data is fed back into the DE algorithm. The algorithm uses this information to mutate and recombine the best-performing vectors to generate a new, "evolved" set of test conditions for the next experimental round.

- Convergence and Validation: Steps 3-5 are repeated. The process converges when new generations no longer produce significant improvements in recovery. The best-performing solution and cooling rate are then validated in a larger-scale vial freezing experiment.

Key Research Reagent Solutions: Table 2: Key Reagents for Advanced Cryopreservation Optimization

| Reagent / Tool | Function / Explanation |

|---|---|

| Differential Evolution (DE) Algorithm | A stochastic search algorithm that efficiently navigates a multi-parameter space (solute concentrations, cooling rate) to find the global optimum for cell recovery [44]. |

| Non-DMSO Cryoprotectants (e.g., Trehalose, Ectoine) | Used to create less toxic, defined freezing solutions. Trehalose is a disaccharide that helps maintain structural integrity, while ectoine is an osmolyte that protects against stress [42] [44]. |

| Controlled-Rate Freezer | Essential for applying precise, reproducible cooling rates critical for protocol optimization and validation [42] [17]. |

| High-Throughput Viability Screening | Using 96-well plates and automated analysis allows for the simultaneous testing of dozens of conditions, making complex optimization feasible [44]. |

Scientific Background and Rationale

Why is a specialized thawing protocol necessary? Dimethyl sulfoxide (DMSO) is the most common cryoprotectant used for cryopreservation of hematopoietic stem cells (HSCs) and mesenchymal stromal cells (MSCs) due to its high efficiency and ability to rapidly penetrate cell membranes [46] [47]. However, when cryopreserved cells are thawed for autologous or allogeneic transplantation, the accompanying DMSO can induce significant adverse effects in patients, including nausea, vomiting, chills, tachycardia, dyspnea, and in rare cases, more severe cardiopulmonary or neurological reactions [46] [47]. Furthermore, the thawing process itself poses a risk of osmotic shock to the cells, which can compromise cell viability, recovery, and ultimately, the efficacy of the transplant [48].

The dual challenge of minimizing DMSO-associated toxicity for the patient and osmotic stress for the cells during the phase transition necessitates a robust and carefully balanced post-thaw protocol. The goal is to ensure high cell recovery and viability while reducing the infusion of toxic agents into the patient [49] [48].

Step-by-Step Thawing and DMSO Reduction Protocol

This protocol is designed for a 100 mL cryobag of peripheral blood stem cells (PBSCs) and is based on established methods used in clinical settings [46]. The process should be performed in a Grade A laminar flow cabinet with a Class B background.

Table 1: Key Reagents and Equipment

| Item | Function/Description |

|---|---|

| Water Bath | For thawing cells, must be calibrated to maintain 37°C. |

| Washing Solution | Normosol-R, Plasma-Lyte 148, or 0.9% NaCl supplemented with agents like hydroxychyl starch (HES) or human serum albumin (HSA) [46]. |

| Anticoagulant | Acid Citrate Dextrose Solution (ACD-A) to prevent clot formation during processing [46]. |

| Centrifuge | Capable of cooling to 4°C and running at 400 g. |

| Cryoprotectant | Dimethyl Sulfoxide (DMSO), typically used at a final concentration of 10% (v/v) for freezing [46] [48]. |

Step 1: Thawing

- Remove the cryobag from liquid nitrogen storage.

- Immediately place the sealed bag in a 37°C water bath.

- Gently agitate the bag until the contents are completely thawed (approximately 5 minutes). Avoid overwarming.

Step 2: Dilution and Washing

- Transfer the entire volume of the thawed cell suspension (mean 98 mL) to a larger, sterile washing bag.

- Gradually add 258 mL of washing solution (e.g., HES) and 42 mL of ACD-A anticoagulant solution to the bag. Gradual dilution is critical to reduce the extracellular DMSO concentration slowly and minimize osmotic shock.

- Mix the suspension gently but thoroughly.

Step 3: Centrifugation

- Centrifuge the bag for 20 minutes at 400 g and 4°C.

- After centrifugation, approximately 300 mL of the supernatant, which contains the majority of the DMSO, is carefully removed without disturbing the cell pellet.

Step 4: Product Formulation and Infusion

- The resulting cell pellet is resuspended in an appropriate infusion solution.

- The final product is labeled and transferred to the clinical department at 2–8°C.

- The product should be administered to the patient within two hours after thawing [46].

Figure 1: DMSO Reduction Workflow. This diagram outlines the key steps for the post-thaw washing process.

Quantitative Data on Cell Recovery

The DMSO reduction process has variable effects on different cell populations. The table below summarizes median recovery rates from a clinical study [46].

Table 2: Cell Recovery Post DMSO Reduction

| Cell Type / Function | Median Recovery (%) | Key Interpretation |

|---|---|---|

| Viable Nucleated Cells (NC) | 120.85% | High recovery; possible explanation is the removal of non-viable cells and debris during washing, effectively concentrating the viable cells. |

| Viable Mononuclear Cells (MNC) | 104.53% | Good recovery, indicating the process is gentle enough to preserve this population. |

| Viable CD34+ Cells | 51.49% | Significant decrease. This highlights a potential risk of losing crucial progenitor cells during processing. |

| Colony-Forming Unit (CFU-GM) Capacity | 93.37% | No significant decrease, suggesting the function of the remaining progenitors is well-preserved. |

Alternative Strategy: Using Lower DMSO Concentrations

An alternative to post-thaw washing is to reduce the DMSO concentration in the freezing media itself. A 2024 systematic review and meta-analysis provides compelling evidence for this approach [48].

Table 3: 5% vs. 10% DMSO Cryopreservation

| Parameter | 5% DMSO Performance vs. 10% DMSO |

|---|---|

| CD34+ Cell Viability | Greater post-thaw viability [48]. |

| Patient Side Effects | Lower rates of adverse events [48]. |

| Engraftment Rates | Minimal impact on neutrophil and platelet engraftment rates [48]. |

Troubleshooting and Frequently Asked Questions (FAQs)

FAQ 1: What are the primary indications for performing DMSO reduction? This procedure is typically reserved for patients at high risk for adverse reactions. Key indications include [46]:

- Impaired Renal Function: Patients with severe renal impairment, such as those with renal failure caused by secondary amyloidosis in multiple myeloma.

- Cardiac Involvement: Patients with primary or secondary amyloidosis of the heart.

- History of Severe Reaction: Patients who have previously experienced a severe adverse reaction to a DMSO-containing stem cell infusion.

FAQ 2: We observed a significant loss of CD34+ cells after washing. What could be the cause? A substantial loss of viable CD34+ cells (median ~50% in some studies) is a known risk of the washing process [46]. This can be due to:

- Physical Cell Loss: Cells are lost during the supernatant removal step.

- Osmotic Stress: Inadequate control of osmotic pressure during dilution and centrifugation can damage sensitive progenitor cells.

- Cell Clumping: Aggregation of cells can lead to inconsistent pellets and loss during processing. Solution: To minimize the risk of prolonged engraftment, ensure the initial collected cell dose is sufficient to tolerate the expected loss. This process should be applied judiciously.

FAQ 3: Is there a safe DMSO dose limit for patient infusion? Yes. The widely accepted safety limit is a daily DMSO dose not exceeding 1 gram per kilogram of patient body weight [46] [47]. For MSC therapies, the delivered DMSO doses are often 2.5–30 times lower than this threshold [47].

FAQ 4: What are the pros and cons of DMSO reduction vs. using lower DMSO concentrations from the start?

Figure 2: Strategy Comparison for DMSO Management. Weighing two primary methods to mitigate DMSO-related issues.

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for the Protocol

| Reagent / Solution | Function in Protocol |

|---|---|

| DMSO (cGMP Grade) | Penetrating cryoprotectant that prevents ice crystal formation during freezing [46] [48]. |

| Hydroxyethyl Starch (HES) | Extracellular cryoprotectant and volume expander; used in washing solutions to help maintain osmotic balance [46]. |

| Human Serum Albumin (HSA) | Protein supplement added to washing or freezing media; helps stabilize cell membranes and reduces mechanical stress [46]. |

| ACD-A Anticoagulant | Citrate-based solution; prevents activation of the coagulation cascade during the washing process [46]. |

| Normosol-R / Plasma-Lyte 148 | Balanced electrolyte solutions used as the base for washing cells; physiocompatible and help maintain cell viability post-thaw [46]. |

Frequently Asked Questions (FAQs)

Q1: What are the key trade-offs when choosing a post-thaw processing method for Cord Blood Mononuclear Cells (CBMCs)? The choice involves balancing cell recovery, purity, and functional fitness, and the optimal method depends on your specific downstream application [4]. The Wash-Only method provides the highest cell yield but results in the lowest purity due to contaminants like red blood cells and granulocytes [4]. Density Gradient and Bead-based methods (e.g., CD15/CD235 depletion) offer higher purity [4]. Functional outcomes also vary; for instance, the EasySep Direct Human PBMC Isolation Kit significantly depletes CD14+ cells, which can correlate with reduced T-cell proliferation, while the Beads method best preserves cell viability over several days in culture [4] [5].

Q2: Does isolating mononuclear cells before cryopreservation improve post-thaw outcomes for cord blood units? No, current research indicates that pre-cryopreservation mononuclear cell isolation does not improve post-thaw CBMC recovery or function compared to the standard practice of using volume-reduced units [4] [5]. Therefore, focusing on optimizing the post-thaw processing method is more impactful for enhancing cell fitness.

Q3: How does granulocyte contamination in a PBMC sample affect downstream experiments? Granulocyte contamination can negatively impact the integrity and function of other immune cells in your sample. Studies have shown a correlation between granulocyte contamination and a significant decline in T-cell proliferation following stimulation. It can also lead to loss of cell number, reduced cell integrity, and increased variability in assays involving Regulatory T cells [50].

Q4: What are the best practices for thawing cryopreserved cells to maximize viability? The thawing process is critical and stressful for cells. Key practices include [51] [52]:

- Thaw Quickly: Remove the vial from liquid nitrogen and immediately place it in a 37°C water bath, gently swirling until only a small ice crystal remains [51].

- Dilute Slowly: Transfer the thawed cells dropwise into a tube containing pre-warmed complete growth medium to gradually reduce the concentration of the cryoprotectant (e.g., DMSO) [51].

- Use Controlled Thawing Devices: For GMP workflows or bedside administration, using a controlled thawing device is recommended over conventional water baths to minimize contamination risk and ensure a consistent, rapid warming rate [13].

- Plate at High Density: Plate the thawed cells at a high density to optimize recovery [51].

Troubleshooting Guides

Poor Cell Recovery Post-Thaw

| Symptom | Possible Cause | Recommended Solution |

|---|---|---|