Overcoming Stem Cell Scalability Manufacturing Challenges: A 2025 Roadmap for Researchers and Developers

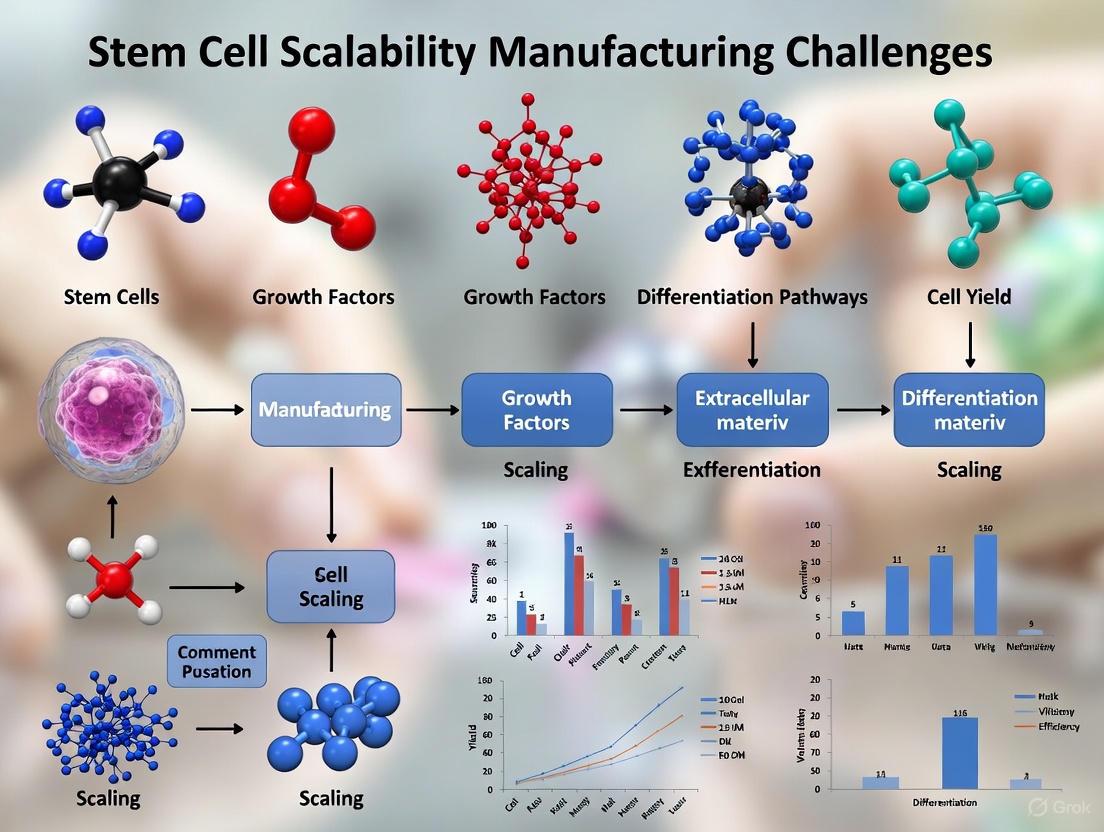

This article provides a comprehensive analysis of the critical challenges and innovative solutions in scaling up stem cell manufacturing for clinical and commercial applications.

Overcoming Stem Cell Scalability Manufacturing Challenges: A 2025 Roadmap for Researchers and Developers

Abstract

This article provides a comprehensive analysis of the critical challenges and innovative solutions in scaling up stem cell manufacturing for clinical and commercial applications. It explores the foundational biological and economic hurdles, details emerging methodologies in bioreactor technology and process automation, outlines strategies for troubleshooting quality control and regulatory compliance, and examines validation frameworks for commercial translation. Aimed at researchers, scientists, and drug development professionals, this review synthesizes current industry perspectives and technological advancements to guide the development of robust, scalable, and cost-effective manufacturing processes for stem cell-based therapies.

The Core Hurdles: Understanding the Biological and Economic Barriers to Scalable Stem Cell Production

The field of stem cell therapy stands at a pivotal crossroads, with remarkable clinical potential tempered by profound manufacturing challenges. As cell therapies advance through clinical trials toward commercialization, prohibitive production costs and complex manufacturing processes threaten to limit patient access and scalability. The global stem cell therapy market, projected to grow at a robust CAGR of 25.26% to reach approximately USD 4,777.4 million by 2034, faces a critical bottleneck: translating laboratory success into economically viable, large-scale production [1].

This manufacturing crisis manifests differently across the two primary therapeutic paradigms. Autologous therapies, which utilize a patient's own cells, offer personalized treatment but face scalability limitations due to their patient-specific nature. Allogeneic therapies, derived from donor cells, promise "off-the-shelf" availability but require massive scaling and sophisticated engineering to avoid immune rejection. Both pathways confront substantial hurdles in achieving the stringent quality standards, regulatory compliance, and economic sustainability necessary for widespread clinical adoption [2] [3].

Understanding the distinct cost drivers for each approach is essential for advancing the field. This technical support center provides researchers and drug development professionals with targeted troubleshooting guidance and analytical frameworks to navigate the complex economic landscape of stem cell therapy manufacturing.

Quantitative Analysis of Cost Drivers

The production costs for stem cell therapies are influenced by multiple interconnected factors that vary significantly between autologous and allogeneic approaches. The table below summarizes the primary cost components and their relative impact on each therapy type.

Table 1: Key Cost Drivers in Stem Cell Therapy Manufacturing

| Cost Component | Impact on Autologous Therapies | Impact on Allogeneic Therapies |

|---|---|---|

| Starting Material Acquisition | Variable patient-specific collection; multiple small batches | Standardized donor screening; large-volume procurement |

| Manufacturing Process | Labor-intensive, small-scale parallel processes | Capital-intensive bioreactor systems; scale-up optimization |

| Quality Control & Testing | Repeated batch-release testing for each patient | Extensive donor cell banking characterization; batch testing |

| Personnel & Expertise | Highly trained technicians for multiple parallel processes | Specialized engineers for bioreactor operation and process control |

| Facility & Equipment | Cleanroom space for multiple simultaneous batches | Large-scale bioreactors and downstream processing equipment |

| Regulatory Compliance | Complex tracking of patient-specific chain of identity | Rigorous characterization of master cell banks; safety studies |

The fundamental economic challenge lies in the inherent tension between personalized medicine and industrial scalability. Autologous therapies typically cost patients between $15,000 and $30,000 for expanded cell products, with higher prices for complex conditions [4]. These costs reflect the labor-intensive nature of manufacturing individual batches, each requiring separate quality validation, sterility testing, and release procedures.

For allogeneic therapies, while the "off-the-shelf" model promises better economics at scale, it requires substantial upfront investment in process development, donor screening, and the establishment of master cell banks that can cost millions of dollars before a single dose is produced [2] [5]. The emerging integration of automation and artificial intelligence offers promising pathways to reduce these costs by enhancing process consistency, predicting optimal culture parameters, and minimizing human intervention [2] [5].

Troubleshooting Guide: Manufacturing Cost Challenges

Frequently Asked Questions on Cost and Scalability

Table 2: Manufacturing Cost and Scalability FAQ

| Question | Expert Insight & Recommendations |

|---|---|

| Why does stem cell manufacturing remain so expensive despite technological advances? | High costs persist due to complex processes requiring specialized equipment, strict environmental controls, extensive quality control testing, and highly trained personnel. Manual, labor-intensive workflows further limit scalability and increase variability [2] [5]. |

| What are the key economic differences between autologous and allogeneic manufacturing? | Autologous therapies involve multiple small batches with repeated quality control, leading to high per-dose costs. Allogeneic requires massive upfront investment in donor screening and process development but offers lower marginal costs through large-scale production [2]. |

| How can automation address current cost challenges? | Automated systems and closed processing reduce manual intervention, minimize contamination risks, enhance process consistency, and enable higher throughput. This is particularly valuable for autologous therapies requiring multiple parallel processes [2] [5]. |

| What role does quality control play in overall costs? | QC can account for 20-30% of total costs. Each batch requires sterility, purity, potency, identity, and viability testing. For autologous therapies, this repeated per-patient testing creates significant economic burden without economies of scale [2] [3]. |

Troubleshooting High Production Costs

Problem: Inconsistent cell yields leading to batch failures and costly manufacturing losses.

Solution: Implement advanced process analytical technologies (PAT) and real-time monitoring systems to detect early deviations. Utilize design of experiment (DOE) approaches to identify critical process parameters and establish proven acceptable ranges for key culture conditions [3].

Prevention Strategy: Develop standardized protocols with clearly defined critical quality attributes (CQAs) and process parameters. Establish robust cell banking systems with comprehensive characterization to ensure starting material consistency [6] [7].

Problem: High labor costs associated with manual processing in cleanroom environments.

Solution: Transition to automated, closed-system bioreactor platforms that reduce manual manipulation and minimize contamination risk. Implement semi-automated systems for routine media exchanges and monitoring tasks [3] [5].

Prevention Strategy: Conduct thorough process mapping to identify automation opportunities. Invest in staff training for automated system operation and maintenance to maximize equipment utilization and efficiency [6].

Problem: Excessive quality control costs from repeated testing regimens.

Solution: Implement quality-by-design (QbD) principles to build quality into the process rather than testing it in the final product. Utilize in-line and at-line monitoring to reduce reliance on end-product testing [3].

Prevention Strategy: Develop platform approaches for similar product types to standardized testing regimens. Work with regulators to establish risk-based testing strategies that maintain safety while reducing redundant analyses [3].

Process Optimization and Workflow Diagrams

Scalable Manufacturing Workflow

The diagram below illustrates a streamlined workflow for scaling up stem cell manufacturing, integrating cost-saving technologies and approaches for both autologous and allogeneic production.

Scalable Manufacturing Pathways for Autologous and Allogeneic Therapies

Process Optimization Decision Framework

Researchers must navigate critical decision points when designing scalable, cost-effective manufacturing processes. The following framework outlines key considerations for process development.

Process Optimization Decision Framework for Cost-Effective Manufacturing

The Scientist's Toolkit: Essential Research Reagents and Solutions

Successful scale-up requires carefully selected reagents and materials that maintain cell quality while supporting manufacturing objectives. The table below outlines key solutions for stem cell manufacturing workflows.

Table 3: Essential Research Reagent Solutions for Stem Cell Manufacturing

| Reagent Category | Key Function | Scale-Up Considerations |

|---|---|---|

| Chemically Defined Media | Supports consistent cell growth and maintenance without variable components | Enables standardized manufacturing; fed-batch formulations reduce media consumption in large-scale cultures [6] |

| 3D Culture Matrices | Provides structural support for cell growth in suspension systems | Facilitates transition to bioreactor systems; critical for high-density 3D culture applications [8] [6] |

| Cell Dissociation Reagents | Enables gentle cell passaging and harvesting with high viability | Optimized formulations maintain cell functionality during scale-up; automation-compatible for high-throughput systems [9] [10] |

| Cryopreservation Solutions | Maintains cell viability and functionality during long-term storage | Critical for cell banking; specialized formulations enhance recovery post-thaw, reducing cell loss costs [7] |

| Quality Control Assays | Monitors critical quality attributes throughout manufacturing | Platform approaches reduce testing costs; in-process assays enable real-time decision making [3] [7] |

The journey toward economically sustainable stem cell manufacturing requires coordinated advances across multiple fronts. Strategic integration of automation platforms, artificial intelligence for process optimization, and quality-by-design principles represents the most promising pathway to reduce costs while maintaining product quality and safety [2] [5].

For autologous therapies, the development of standardized, closed automated systems that can process multiple patient-specific batches in parallel is essential for improving efficiency. For allogeneic approaches, advancing high-density bioreactor technologies and optimizing cryopreservation methods will enable the true "off-the-shelf" potential of these therapies [3] [6].

The future of stem cell manufacturing will likely see convergence between these approaches, with hybrid models emerging that leverage the economic advantages of allogeneic platforms while maintaining the personalized benefits of autologous approaches. Through continued innovation in process development, analytical methods, and regulatory science, the field can overcome current cost barriers and fulfill the promise of regenerative medicine for broader patient populations.

Technical Support Center

This technical support center provides targeted guidance for researchers addressing the critical challenge of biological variability in stem cell manufacturing. The following troubleshooting guides, FAQs, and structured protocols are designed to help you mitigate the impact of donor and starting material inconsistency on your process robustness and final product quality.

Troubleshooting Guides

Troubleshooting Excessive Differentiation in hPSC Cultures

Problem: Excessive differentiation (>20%) in human pluripotent stem cell (hPSC) cultures.

| Potential Cause | Recommended Action | Rationale & Additional Context |

|---|---|---|

| Old or degraded culture medium | Ensure complete medium kept at 2-8°C is less than 2 weeks old [9]. | Culture medium stability is critical for consistent performance. |

| Over-manipulation of cultures | Avoid having the culture plate out of the incubator for more than 15 minutes at a time [9]. | Environmental fluctuations stress cells and can induce differentiation. |

| Suboptimal colony size and density | Passage cultures when colonies are large and compact; avoid overgrowth. Decrease colony density by plating fewer cell aggregates [9]. | Over-confluence is a common trigger for spontaneous differentiation. |

| Inconsistent cell aggregate size | Ensure cell aggregates generated after passaging are evenly sized [9]. | Uniform aggregate size ensures consistent growth and differentiation signals. |

| Oversensitivity to passaging reagents | Reduce incubation time with passaging reagents (e.g., ReLeSR) [9]. | Cell lines can exhibit variable sensitivity to enzymatic or chemical dissociation. |

Troubleshooting Low Cell Recovery and Viability Post-Cryopreservation

Problem: Low cell recovery or viability after thawing starting material or final product.

| Potential Cause | Recommended Action | Rationale & Additional Context |

|---|---|---|

| Suboptimal thawing technique | Thaw cells quickly (≤2 mins at 37°C). Do not thaw cells directly in medium; instead, transfer to a tube first, then add pre-warmed medium drop-wise while swirling [10]. | Rapid, controlled dilution minimizes osmotic shock, which is critical for fragile primary and stem cells. |

| Incorrect cryopreservation medium | Use specialized, serum-free cryopreservation media (e.g., CryoStor CS10) instead of standard DMSO-containing media [11]. | Formulated cryomedia provide superior protection and enhance post-thaw recovery and function. |

| Insufficient or excessive cell concentration | Count cell viability with trypan blue after thawing. Seed at recommended density (e.g., >1x10^5 viable cells/cm² for H9-derived NSCs) [10]. | Seeding at improper densities impedes recovery and expansion. |

| Transient warming events during storage | Monitor and control storage conditions; minimize cumulative impact of transient warming events [12]. | Temperature fluctuations during storage degrade product quality even in nominally frozen conditions. |

| Incorrect analysis | Characterize cells post-thaw, accounting for cells lost to lysis [12]. | Standard viability assays may not capture full functional competence. |

Frequently Asked Questions (FAQs)

Donor and Starting Material

Q1: Why does my manufacturing success rate vary significantly between different donor samples?

The donor is the primary driver of variability in cell manufacturing processes. The mononuclear cell product will always be a direct reflection of the cell populations circulating in the donor at the time of collection [12]. Key factors include:

- Clinical Indication: Patients with different diseases have vastly different starting blood counts (e.g., chronic lymphocytic leukemia vs. lymphoma) [12].

- Prior Treatment: Years of cytotoxic chemotherapy can lead to a T-cell population that is suboptimal for expansion [12].

- Donor Demographics: Age, genetics, and health status contribute to inherent biological variability [12].

Q2: What are the risks of developing therapies using only healthy donor material?

Relying solely on healthy donor material introduces substantial risks for clinical translation [13]:

- Faulty Preclinical Data: Healthy cells may not accurately reflect disease-specific mechanisms, leading to inaccurate predictions of therapeutic efficacy and safety [13].

- Manufacturing Failures: Processes optimized for robust healthy cells might prove ineffective or damaging for more fragile diseased cells, leading to low yields and high variability [13].

- Clinical Failure: Therapies showing promise in healthy models may fail in patients, as diseased cells can respond differently, leading to unforeseen adverse events [13].

Q3: How can I extend the shelf-life and stability of my starting material to gain manufacturing flexibility?

While fresh material is ideal, its quality declines immediately post-collection. Two primary methods can extend stability [11]:

- Hypothermic Storage: Using specialized storage media (e.g., HypoThermosol) at 2-8°C can maintain viable cell recovery and function for up to 48 hours post-collection [11].

- Cryopreservation: Freezing starting material (e.g., in CryoStor CS10) is the best method for long-term stability (beyond 96 hours) and enables simplified, "level-loaded" manufacturing scheduling rather than on-demand processing [11].

Process and Manufacturing

Q4: My process performs well at a small scale but becomes variable and inefficient when scaled up. What could be wrong?

Scaling a process that was not optimized for robustness early in development often leads to substandard reproducibility. Variability can occur at multiple levels [14]:

- Raw Materials: Media and reagent variations can cause differences in titer and critical quality attributes (CQAs) [14].

- Equipment Transition: Cell behavior can change when moving from 2D flasks to 3D bioreactors, affecting transfection efficacy and cell quality [14].

- Process Parameters: Critical process parameters (CPPs) that were easy to control in small-scale equipment may be harder to manage consistently at larger scales [14].

Q5: How can I make my bioprocess more robust against inherent biological variability?

Implementing a systematic approach is key to improving robustness [15]:

- Adopt QbD Principles: Use Quality-by-Design (QbD) and Design of Experiments (DoE) to identify and control critical process parameters [15] [14].

- Leverage Advanced Monitoring: Integrate advanced sensors and AI-driven models to dynamically track CQAs and predict culture trajectories, allowing for proactive interventions [16].

- Standardize and Automate: Use standardized automated methods to overcome inter- and intra-observer variation in assays and cell culture handling [12].

Protocol: Evaluating Preservation Methods for Leukapheresis Starting Material

This protocol, based on collaborative studies, outlines how to compare hypothermic storage versus cryopreservation for extending the shelf-life of donor-derived leukapheresis products [11].

1. Objective: To assess the impact of different preservation methods and storage durations on the viability, recovery, and function of leukapheresis starting material.

2. Materials:

- Donor leukapheresis product

- HypoThermosol storage medium

- CryoStor CS10 cryopreservation medium

- Controlled-rate freezer

- Liquid nitrogen storage vapor

- Cell culture reagents for functional assays (e.g., for CD14+ cell function)

- Flow cytometry equipment and antibodies (e.g., for CD14, CD3, CD45RA, CCR7)

3. Methodology:

- Collection & Splitting: Following leukapheresis collection, process the product and split it into multiple, identical aliquots.

- Preservation Conditions:

- Condition A (Hypothermic): Mix leukapheresis product with HypoThermosol at a 1:1 ratio. Hold at 2-8°C [11].

- Condition B (Cryopreserved): Mix leukapheresis product with CryoStor CS10 at a 1:1 ratio. Freeze using a controlled-rate freezer and store in liquid nitrogen vapor [11].

- Condition C (Unmanipulated Control): Hold a portion of the leukapheresis product at 2-8°C without any additive [11].

- Time-Point Analysis: At predetermined time points (e.g., 0, 24, 48, 96, 120 hours), thaw cryopreserved samples and analyze all conditions in parallel.

- Key Assessments:

- Viable Cell Recovery: Use trypan blue exclusion and cell counting.

- Cell-Specific Recovery & Viability: Use flow cytometry to analyze specific cell populations (e.g., WBC, CD14+ monocytes, CD3+ T cells).

- Cell Function: Perform functional assays relevant to the cell type (e.g., monocyte function assays).

- Phenotypic Markers: Analyze markers of cell state, such as T cell naivety (CD45RA+/CCR7+) [11].

4. Data Analysis: Compare the recovery, viability, and function across the different preservation conditions and over time to determine the optimal storage method for your specific downstream manufacturing process.

The table below summarizes typical outcomes from the protocol above, illustrating the trade-offs between different preservation strategies [11].

| Preservation Method & Condition | Storage Temp | Viable WBC Recovery (at 48-96h) | Key Functional/Phenotypic Notes | Ideal Use Case |

|---|---|---|---|---|

| Unmanipulated Leukapheresis | 2-8°C | Dramatic decrease after 48 hours | T cell naivety ~50-60% at 96h | Manufacturing within 48h of collection |

| Hypothermic (HypoThermosol) | 2-8°C | 78-94% (similar to cryo at 24h) | CD14+ cell function maintained | Short-term stability (up to 48-72h); maintains function |

| Cryopreserved (CryoStor CS10) | ≤-135°C | Stable over 120h | T cell naivety reduced to ~30% | Long-term storage; geo-graphical separation; scheduling flexibility |

Experimental Workflow for Evaluating Starting Material Preservation

The Scientist's Toolkit: Key Research Reagent Solutions

This table details essential materials and their functions for managing variability in stem cell and cell therapy processes.

| Item | Function & Application | Key Consideration |

|---|---|---|

| Specialized Cryopreservation Media (e.g., CryoStor) | Serum-free, formulated media designed to minimize freezing-induced cell damage and improve post-thaw recovery and function [11]. | Superior to homemade DMSO/serum mixes; provides consistent, xeno-free composition for clinical applications. |

| Hypothermic Storage Media (e.g., HypoThermosol) | An optimized solution for the short-term (2-8°C) storage and shipment of cells, designed to slow metabolism and support viability better than saline or plasma [11]. | Extends the viable shelf-life of starting materials, providing a buffer for logistical delays. |

| Rock Inhibitor (Y-27632) | A small molecule that significantly improves the survival of human pluripotent stem cells (hPSCs) after single-cell passaging and thawing from cryopreservation [10]. | Critical for preventing anoikis; use at time of passaging or post-thaw for challenging cell lines. |

| Defined, Feeder-Free Culture Systems (e.g., mTeSR, Essential 8) | Chemically defined, xeno-free media and matrix combinations that support the robust growth of hPSCs without feeder cells, reducing variability [9] [10]. | Essential for standardizing the culture environment and minimizing introduction of undefined components. |

| GMP-Grade Cell Separation Reagents | Reagents (e.g., for Ficoll density gradient, CD3+ selection) that are manufactured under Good Manufacturing Practice for clinical-grade cell processing [12]. | Availability of GMP-grade reagents for cell enrichment is currently limited but crucial for clinical translation. |

Logical Flow for Managing Donor Variability

Troubleshooting Guide: 3D Suspension Culture

This guide addresses common challenges researchers face when transitioning from 2D planar cultures to 3D suspension systems for scaling stem cell production.

Problem 1: Poor Cell Viability and Growth in 3D Suspension

- Symptoms: Slow or no cell growth, excessive cell debris, low viability post-passaging.

- Potential Causes and Solutions:

- Cause: Inoculation density is too low. Suspension cells are density-dependent and state is better at high density [17].

- Solution: Ensure routine inoculation density is maintained at 3-5×10⁵ cells/mL. When cells are in poor condition, passage via replenishment or half-medium exchange to avoid centrifugation cell loss [17].

- Cause: Excessive shear stress from agitation damaging delicate cells [18] [19].

- Solution: Optimize agitation speed and impeller design; use gentle rocking platforms for shear-sensitive cells. Supplement media with surfactants like Pluronic F-68 to protect cells [18] [19].

- Cause: Cells are undergoing an adaptation phase after transition from 2D [20].

- Solution: Monitor key metrics. In mTeSR 3D, some cell lines show lower expansion for 1-2 passages but should fully adapt by passage three. Use TeSR-AOF 3D medium which may not require an adaptation phase [20].

Problem 2: Excessive Cell Aggregation or Clumping

- Symptoms: Cells form large, irregular clumps instead of well-defined aggregates; necrotic centers may develop in large clumps.

- Potential Causes and Solutions:

- Cause: Normal characteristic for some cell lines (e.g., NK92, JURKAT grow in clusters) [17].

- Solution: For cells that naturally grow in clusters, avoid frequent blowing of aggregates. When density increases and state improves, cells may disperse naturally [17].

- Cause: Suboptimal culture conditions or serum quality [17].

- Solution: Rest cultures (less operation/observation). For low cell density clumping, add serum (5%). If all cells clump unexpectedly, consider testing different serum brands [17].

- Cause: Aggregation leads to necrotic core formation due to diffusion limitations [21] [20].

- Solution: Control aggregate size by optimizing passaging techniques and agitation rates. For hPSCs, target aggregate size of 50-200 μm [9] [20].

Problem 3: Unintended Differentiation in hPSC 3D Cultures

- Symptoms: Loss of pluripotency markers, spontaneous differentiation despite using growth media.

- Potential Causes and Solutions:

- Cause: Suboptimal aggregate size or culture conditions [22] [9].

- Solution: Ensure cell aggregates generated after passaging are evenly sized. Remove differentiated areas prior to passaging. Do not allow cultures to overgrow [9].

- Cause: Mechanical forces in bioreactors causing epigenetic changes [22].

- Solution: Use specialized bioreactors like PBS-MINI designed for shear-sensitive hPSCs. Monitor pluripotency markers (OCT4, TRA-1-60) every 5 passages [22] [20].

- Cause: Old or suboptimal culture medium [9].

- Solution: Use fresh complete cell culture medium (less than 2 weeks old when stored at 2-8°C). Avoid having culture vessels out of incubator for more than 15 minutes [9].

Problem 4: Challenges in Monitoring and Characterization

- Symptoms: Difficulty assessing cell density, viability, and differentiation status in 3D aggregates.

- Potential Causes and Solutions:

- Cause: Traditional sampling techniques ineffective in 3D systems [22].

- Solution: For counting clumpy suspensions, use automated counters like NucleoCounter NC-250 with lysis protocols to obtain total and viable cell counts. Alternatively, use clump counting with consistent clump sizes [20].

- Cause: Limited visualization and microscopy in 3D structures [23].

- Solution: Implement regular sampling with dissociation for flow cytometry analysis. Use systems designed for easy microscopy like OrganoPlates [23] [20].

Frequently Asked Questions (FAQs)

Q1: What are the key advantages of 3D suspension culture over 2D for large-scale production?

A: 3D suspension culture offers several critical advantages for scale-up:

- Enhanced Scalability: Enables large-scale production in bioreactors, overcoming surface area limitations of 2D systems [20].

- Efficiency: Fed-batch workflows minimize labor and media costs while preventing aggregate loss [20].

- Matrix Elimination: Reduces reliance on expensive extracellular matrices required for 2D cultures [20].

- Homogeneity: Provides more homogeneous cell population compared to adherent cultures [18].

- Physiological Relevance: Better mimics in vivo conditions with enhanced cell-cell interactions and tissue-like structures [21] [23].

Q2: How long does adaptation take when transitioning hPSCs from 2D to 3D suspension culture?

A: Adaptation time depends on cell line, medium, and culture conditions:

- With TeSR-AOF 3D medium, little to no adaptation phase may be needed [20].

- In mTeSR 3D, some cell lines experience lower expansion during first 1-2 passages but typically fully adapt by passage 3 [20].

- Monitor key quality attributes including aggregate morphology, viability, and expansion at each passage to gauge adaptation success [20].

Q3: Can we cryopreserve and recover hPSCs directly in 3D suspension culture?

A: Yes, cryopreserved hPSCs can be thawed directly into 3D suspension culture, bypassing 2D expansion [20]. For optimal recovery:

- Freeze clumps generated from 3D hPSC cultures using CryoStor CS10 [20].

- Use a 70-micron reversible strainer instead of 37-micron to maintain slightly larger clumps, improving post-thaw viability [20].

Q4: How do we prevent necrotic core formation in 3D aggregates?

A: Necrotic cores form due to diffusion limitations in large aggregates. Prevention strategies include:

- Controlling aggregate size through optimal passaging and agitation [20].

- Ensuring adequate oxygen and nutrient exchange through proper bioreactor design and mixing [18].

- Monitoring aggregate morphology and adjusting culture parameters when "pockmarking" appears [20].

Q5: What bioreactors are most effective for sensitive hPSCs in 3D suspension?

A: hPSCs are highly shear-sensitive. The most reproducible results have been observed with:

- Nalgene Storage Bottles (15-60 mL scale) [20].

- PBS-MINI Bioreactors (100-500 mL scale) [20].

- For cultures larger than 500 mL, further optimization is ongoing [20].

Quantitative Data Comparison: 2D vs 3D Culture Systems

Table 1: Performance Metrics for Scalable Culture Systems

| Parameter | Traditional 2D | 3D Suspension (Microcarrier) | 3D Spheroid/Aggregate |

|---|---|---|---|

| Max Scale Achievable | Limited by surface area (multilayer stacks, roller bottles) [22] | High (bioreactors with microcarriers) [22] | High (suspension bioreactors) [20] |

| Relative Cell Yield per Volume | Low (surface area-limited) [22] | High (increased volumetric density) [22] | High (3D structure enables density) [20] |

| Labor Intensity | High (multiple vessels, manual handling) [22] | Moderate (automation possible) [18] | Low (fed-batch workflows) [20] |

| Media Consumption | Higher per cell [23] | Optimized [18] | Efficient (fed-batch approach) [20] |

| Physiological Relevance | Low (monolayer, unnatural polarization) [21] [23] | Moderate (3D environment) [21] | High (tissue-like structures) [23] [24] |

| Shear Stress Sensitivity | Low (static culture) [19] | High (agitation required) [18] [19] | Moderate (aggregates more resilient) [20] |

| Typical hPSC Expansion (Daily Fold) | Variable [20] | 1.4-2.0 [20] | 1.4-2.0 [20] |

Table 2: Troubleshooting 3D Culture Parameters

| Problem | Critical Parameters to Monitor | Optimal Range/Target |

|---|---|---|

| Poor Cell Growth | Inoculation density [17] | 3-5×10⁵ cells/mL [17] |

| Excessive Aggregation | Aggregate size [9] | 50-200 μm for hPSCs [9] |

| Unintended Differentiation | Pluripotency markers [20] | OCT4, TRA-1-60 (regular monitoring) [20] |

| Necrotic Core Formation | Aggregate size & morphology [20] | Uniform aggregates, avoid oversized clusters [20] |

| Low Post-Thaw Viability | Cryopreservation clump size [20] | Use 70-micron strainer for larger clumps [20] |

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagents for 3D Suspension Culture

| Reagent/Product | Function | Application Notes |

|---|---|---|

| TeSR-AOF 3D Medium | Animal-origin free media for fed-batch 3D culture [20] | Provides most consistent expansion across passages; enhanced viral safety [20] |

| mTeSR 3D Medium | First media enabling fed-batch workflows [20] | Saves time and media with daily feeds; no medium exchanges on non-passaging days [20] |

| Gentle Cell Dissociation Reagent (GCDR) | Non-enzymatic dissociation for aggregate breakdown [20] | For single-cell passaging: longer incubation (10-15 min at 37°C) with trituration [20] |

| CryoStor CS10 | Cryopreservation medium for 3D cultures [20] | Preserves viability when freezing clumps from 3D hPSC cultures [20] |

| Extracellular Matrices (ECMs) | Hydrogels providing 3D scaffolding [23] | Collagen, laminin, fibrin; provides microenvironment for morphogenesis [24] |

| Microcarriers | Beads providing growth substrate in suspension [19] | Enables adherent cells to grow in suspension bioreactors [19] |

| Anti-Clumping Agents | Supplements to reduce cell aggregation [18] | Pluronic F-68 protects against shear stress [18] |

Experimental Protocols

Protocol 1: Transitioning hPSC Differentiation from 2D to 3D Suspension Culture

Purpose: Adapt existing 2D differentiation protocols to 3D suspension systems for scalable production.

Workflow Overview:

Step-by-Step Methodology:

Confirm High-Quality hPSCs Before Differentiation

- Expand hPSCs in TeSR-AOF 3D for at least two passages

- Assess key quality metrics: aggregate morphology, marker expression (OCT4, TRA-1-60), and genetic stability [20]

Validate the Standard 2D Differentiation Protocol

- Use existing STEMdiff kits or established protocols

- Confirm differentiation efficiency in 2D culture first - if it doesn't work in 2D, it likely won't work in 3D [20]

Develop Reproducible 3D hPSC Culture Techniques

- Master aggregate formation, media change techniques, and passaging before differentiation

- Utilize resources like 3D hPSC On-Demand Courses and technical manuals [20]

Optimize Differentiation at Small Scale

- Begin with 6-well plates on an orbital shaker

- Optimize key parameters: media change strategy, differentiation timing, and seeding density [20]

Scale Up in Bioreactors

- Progress to Nalgene Storage Bottles (15-60 mL) then PBS-MINI Bioreactors (100-500 mL)

- Monitor differentiation efficiency through marker expression and yield

- Optimize agitation rates and media exchange protocols [20]

Protocol 2: Assessing Pluripotency in 3D hPSC Aggregates

Purpose: Regularly monitor stem cell quality and prevent spontaneous differentiation during 3D culture.

Key Assessment Metrics:

Monitoring Framework:

- At Each Passage: Assess expansion and viability. Expected daily fold expansion ranges from 1.4 to 2 - deviations may indicate suboptimal conditions [20].

- Daily Monitoring: Evaluate aggregate morphology. "Pockmarking" often correlates with undifferentiated hPSC marker expression [20].

- Every 5 Passages: Dissociate aggregates for flow cytometry analysis of undifferentiated hPSC markers (OCT4, TRA-1-60) [20].

- Every 5-10 Passages: Assess genetic stability and functional pluripotency using trilineage differentiation kits [20].

Technical Diagrams

3D Culture System Decision Framework

This technical support resource provides stem cell researchers and bioproduction professionals with practical guidance for overcoming the scalability bottleneck through implementation of 3D suspension culture systems. The contained troubleshooting guides, FAQs, and protocols address the most common challenges encountered when transitioning from 2D to 3D systems for large-scale manufacturing applications.

Troubleshooting Guides

This section addresses common challenges in scaling up stem cell manufacturing and provides evidence-based corrective actions to protect critical quality attributes (CQAs).

Guide 1: Troubleshooting Loss of Cell Potency During Bioreactor Scale-Up

Problem: A significant drop in cell differentiation potential and therapeutic functionality is observed when transitioning from 2D flask cultures to 3D bioreactor systems.

| Observation | Potential Root Cause | Corrective Action |

|---|---|---|

| Reduced differentiation to osteoblasts, adipocytes, and chondroblasts [25] | Suboptimal dissolved oxygen (DO) levels [25] | Implement DO control strategies and establish a proven acceptable range for your cell line. |

| Decreased expression of key immunophenotype markers (CD105, CD73, CD90) [25] | Inadequate nutrient supply or waste product accumulation [25] | Monitor key metabolites (e.g., glucose, lactate) and establish feeding schedules or perfusion rates. |

| High cell viability but low in vivo efficacy | Inconsistent microcarrier colonization in agitated systems | Optimize inoculation strategy and agitation parameters to minimize shear stress while ensuring uniform cell distribution. |

| Increased batch-to-batch variability | Uncontrolled physiochemical properties (e.g., pH shifts) [25] | Tighten process controls on pH and temperature; define acceptable operating ranges for all critical process parameters (CPPs). |

Guide 2: Addressing Product Variability and Contamination Risks

Problem: Inconsistent cell product quality and safety between manufacturing batches, including failed safety tests.

| Observation | Potential Root Cause | Corrective Action |

|---|---|---|

| Positive sterility test (bacterial, fungal, mycoplasma) [26] | Compromised aseptic processing during manual operations [26] | Implement closed-system processing and automated bioreactors where possible; validate aseptic techniques with media fills [26]. |

| Detection of endotoxin [26] | Contaminated raw materials or reagents | Source GMP-grade reagents and establish rigorous quality control testing for all incoming materials [26]. |

| Karyotype abnormalities after successive cultures [26] | Genetic instability due to prolonged expansion [26] | Establish a maximum in vitro cell age limit; perform regular karyotype and genetic stability testing [26]. |

| Failed tumorigenicity assays (e.g., positive in soft agar) [26] | Presence of residual undifferentiated cells or transformed cells [26] | Improve purification processes; employ more sensitive tumorigenicity assays like digital soft agar or cell proliferation characterization tests [26]. |

Frequently Asked Questions (FAQs)

Q1: What are the minimal quality attributes that must be tested for a mesenchymal stem cell (MSC) product before release? According to the International Society for Cell & Gene Therapy (ISCT), the minimal criteria include plastic adherence, positive expression of CD105, CD73, and CD90, lack of expression of hematopoietic markers (CD45, CD34, etc.), and the ability to differentiate into osteoblasts, adipocytes, and chondroblasts in vitro [25]. Cell count and viability are also ubiquitously measured as they define the product dosage [25].

Q2: How can we ensure our scaled-up manufacturing process is compliant with regulatory standards? A Quality-by-Design (QbD) approach is recommended [25]. Begin by defining a Quality Target Product Profile (QTPP). Use this to identify your product's CQAs. Then, systematically evaluate your production process to define the Critical Process Parameters (CPPs) that control these CQAs. This risk-based framework, detailed in ICH Q8, is recognized by regulators like the EMA and FDA [25].

Q3: What are the major challenges when translating a research-scale process to GMP-compliant manufacturing? Key challenges include ensuring a reliable supply of GMP-grade raw materials, managing donor-to-donor variability, developing scalable cell expansion protocols that maintain phenotype, and adapting facilities to meet GMP requirements for contamination control. A critical step is process validation to ensure consistent product quality, safety, and efficacy [26].

Q4: What advanced technologies can help overcome scaling challenges for Advanced Therapy Medicinal Products (ATMPs)? Novel technologies such as automated closed-system bioreactors, organoids for more accurate disease modeling, and artificial intelligence (AI) for improved process monitoring and data management are being explored to enhance the consistency, scalability, and precision of ATMP production [26].

| CQA Category | Specific Attribute | Standard Analytical Method | Typical Target / Acceptance Criterion |

|---|---|---|---|

| Dosage & Viability | Total Cell Number | Automated cell counter / Hemocytometer | Defined by dose; >70-90% viability (product-specific) |

| Cell Viability | Trypan blue exclusion / Flow cytometry | ||

| Identity / Potency | Immunophenotype (Positive) | Flow Cytometry | ≥ 95% positive for CD105, CD73, CD90 |

| Immunophenotype (Negative) | Flow Cytometry | ≤ 2% positive for CD45, CD34, etc. | |

| Differentiation Potential | In vitro trilineage differentiation (Staining, qPCR) | Demonstrated differentiation into fat, bone, and cartilage | |

| Product Quality | Genetic Stability | Karyotype analysis / SNP array | No major abnormalities detected |

| Sterility | Sterility test (e.g., BacT/ALERT) | No growth of aerobic/anaerobic bacteria, fungi | |

| Endotoxin | LAL test | Below specified limit (e.g., <5.0 EU/kg/hr) |

| Critical Process Parameter (CPP) | Related Unit Operation | Impact on Critical Quality Attributes (CQAs) |

|---|---|---|

| Dissolved Oxygen (DO) | Bioreactor Cultivation | Affects cell growth, metabolism, differentiation potential, and overall potency [25]. |

| pH Level | Bioreactor Cultivation | Impacts cell health, viability, and growth rate; shifts can indicate metabolic changes [25]. |

| Agitation Speed | Bioreactor Cultivation | Influences cell attachment to microcarriers, nutrient distribution, and shear stress (which can damage cells). |

| Nutrient & Metabolite Levels | Media Formulation & Feeding | Glucose, glutamine, lactate levels directly affect volumetric productivity, cell growth, and viability [25]. |

| Cell Source & Donor | Cell Isolation | A primary source of biological variability impacting growth rate, potency, and functionality [25]. |

Experimental Protocols

Protocol 1: In Vitro Trilineage Differentiation Potency Assay for MSCs

Objective: To confirm the differentiation capacity of manufactured MSCs into adipocytes (fat), osteoblasts (bone), and chondroblasts (cartilage) as a key potency assay [25].

Materials:

- Cells: Human MSCs at passage number P3-P5.

- Media: Commercial, standardized differentiation kits for adipogenesis, osteogenesis, and chondrogenesis are recommended.

- Staining Reagents:

- Adipogenesis: Oil Red O stain for lipid droplets.

- Osteogenesis: Alizarin Red S stain for calcium deposits.

- Chondrogenesis: Alcian Blue stain for sulfated proteoglycans.

- Equipment: 6-well and 24-well tissue culture plates, centrifuge, CO₂ incubator, microscope.

Methodology:

- Cell Seeding:

- Adipogenic/Osteogenic Differentiation: Seed MSCs at a defined density (e.g., 2.1x10⁴ cells/cm²) in 6-well plates in standard growth media. Allow cells to reach 100% confluence. Change to differentiation media 24 hours post-confluence.

- Chondrogenic Differentiation: Pellet 2.5x10⁵ MSCs in a 15mL conical tube. Culture the pellet in chondrogenic differentiation media.

- Differentiation:

- Maintain cultures for 14-21 days, changing the differentiation media every 2-3 days.

- Include control groups cultured in standard growth media for each lineage.

- Staining and Analysis:

- At endpoint, wash cells/pellets with PBS and fix with 4% paraformaldehyde.

- Perform lineage-specific staining:

- Adipocytes: Stain with Oil Red O and counterstain with Hematoxylin. Red lipid vacuoles confirm differentiation.

- Osteoblasts: Stain with Alizarin Red S. Red-orange mineralized matrix confirms differentiation.

- Chondrocytes: Embed pellets in paraffin, section, and stain with Alcian Blue. Blue-stained extracellular matrix confirms differentiation.

- Documentation: Image stained cultures under a brightfield microscope. A successful assay shows clear positive staining in differentiation groups compared to controls.

Protocol 2: Monitoring Process Parameters in a Stirred-Tank Bioreactor

Objective: To monitor and control key process parameters during MSC expansion in a bioreactor to ensure consistent product quality.

Materials:

- Bioreactor System: Stirred-tank bioreactor with control unit.

- Sensors: Pre-calibrated pH and dissolved oxygen (DO) probes.

- Media: Serum-free or xeno-free cell culture media.

- Cells & Carriers: Human MSCs and compatible microcarriers.

- Analytical Tools: Bioanalyzer or blood gas analyzer for metabolite testing.

Methodology:

- Bioreactor Setup & Calibration: Assemble the bioreactor vessel and sterilize (e.g., by autoclaving). Calibrate the pH and DO probes according to the manufacturer's instructions.

- Parameter Setpoints: Define and set the acceptable ranges for CPPs based on prior development data. Common setpoints include:

- pH: Typically 7.2 - 7.4

- Dissolved Oxygen (DO): Often 20-50% air saturation

- Temperature: 37°C

- Agitation Speed: Speed must be sufficient to keep microcarriers in suspension without causing excessive shear stress (e.g., 50-100 rpm).

- Process Monitoring:

- Real-time: The control system should log pH, DO, and temperature data continuously.

- Off-line Sampling: Take daily samples to count cells and assess viability (e.g., with trypan blue). Measure metabolite concentrations (glucose, lactate, glutamine) to understand nutrient consumption and waste accumulation.

- Process Control: Use the controller to automatically adjust gas flow rates (O₂, N₂, CO₂) to maintain pH and DO within their set ranges. Adjust feeding strategies based on metabolite data.

Workflow and Pathway Diagrams

Diagram Title: QbD Framework for Process Development

Diagram Title: MSC Manufacturing Workflow

The Scientist's Toolkit: Research Reagent Solutions

| Essential Material / Reagent | Function in MSC Manufacturing |

|---|---|

| GMP-grade Culture Media | Provides nutrients and growth factors for cell expansion. Using standardized, GMP-grade media reduces batch-to-batch variability and supports regulatory compliance [26]. |

| Microcarriers | Provides a high-surface-area scaffold for adherent MSCs to grow on in 3D bioreactor systems, enabling scalable expansion. |

| Characterized Cell Banks | A well-characterized Master Cell Bank (MCB) ensures a consistent and reliable starting material, reducing variability caused by the cell source [25]. |

| Flow Cytometry Antibody Panels | Kits containing fluorescently-labeled antibodies against positive (CD105, CD73, CD90) and negative (CD45, CD34) markers to confirm MSC immunophenotype identity [25]. |

| Trilineage Differentiation Kits | Standardized, off-the-shelf kits containing optimized media and reagents for performing adipogenic, osteogenic, and chondrogenic differentiation assays to assess cell potency [25]. |

| Closed-System Bioprocess Containers | Single-use bags and tubing sets for fluid transfer and cell culture that minimize the risk of contamination during manufacturing, supporting aseptic processing [26]. |

Technical Support Center: Cold Chain Management for Advanced Therapies

Frequently Asked Questions (FAQs)

Q1: What are the most critical points for temperature monitoring in a stem cell product's journey? The most critical points are during cross-docking, last-mile delivery, and loading/unloading, where products are most vulnerable to temperature excursions [27]. Real-time monitoring with IoT sensors at these stages allows for immediate corrective action.

Q2: Our facility faces frequent power outages. How can we ensure the integrity of cryogenically stored cell therapies? Implement redundant systems and contingency protocols [27]. This includes backup power generators (e.g., UPS systems) and backup transport plans. For long-term storage in off-grid areas, investing in liquid nitrogen dry shippers that can maintain temperatures below -150°C for extended periods without external power is recommended [28].

Q3: What is the primary regulatory challenge when scaling out a manufacturing process to a new location? The most critical challenge is demonstrating product comparability after the manufacturing process change [26]. Regulatory authorities like the FDA and EMA require a risk-based comparability assessment, extended analytical characterization, and staged testing to ensure that the change does not impact the product's critical quality attributes (CQAs), safety, or efficacy.

Q4: How can we improve supply chain resilience for critical single-source reagents? For reagents facing shortages, such as Hespan in cord blood processing, a dual strategy is effective [29]. Short-term, establish "good-neighbor" agreements with other facilities to share available lots. Long-term, qualify alternative international vendors or supplement approved procedures to include a method that does not use the scarce reagent, though this requires a demonstration of product comparability.

Q5: What logistical model can help extend the reach of cell and gene therapies to remote clinics? The hub and spoke model is a promising framework [30]. In this model, a central, well-resourced facility (the hub) handles complex manufacturing and storage, while smaller, local health facilities (spokes) manage patient identification, cell collection, and final product administration. This model is scalable, efficient, and adaptable to different regional needs.

Troubleshooting Guides

Guide 1: Addressing Temperature Excursions During Transport

Problem: A temperature tracker alert indicates a cryogenic shipment of CAR-T cells has experienced a temperature rise above the -150°C threshold for 15 minutes.

Immediate Actions:

- Isolate the Shipment: Upon receipt, do not mix the affected shipment with other inventory. Move it to a designated quarantine area in the cryogenic storage unit [27].

- Document Everything: Record the IoT sensor data, including the exact duration and magnitude of the temperature deviation. Note the external conditions and any potential causes noted by the logistics provider [27].

- Assess Product Impact: Consult pre-defined stability data for the product. The quality control unit must review the deviation against validated stability parameters to determine if the product's critical quality attributes (CQAs) are likely compromised [26].

Corrective and Preventive Actions (CAPA):

- Investigate Root Cause: Was the excursion due to equipment failure (e.g., liquid nitrogen tank issue), prolonged handling during transfer, or a transport delay?

- Review Packaging: Evaluate the integrity of the dry shipper and the remaining liquid nitrogen volume. Consider using advanced thermal packaging with phase-change materials for better thermal buffering [27].

- Optimize Routing: Use AI-driven route planning to minimize transit times and avoid routes prone to delays [27].

Guide 2: Managing Supply Disruption of a Critical Processing Reagent

Problem: The sole supplier of a GMP-grade reagent essential for your cell culture process announces a discontinuation or allocation.

Immediate Actions:

- Inventory Assessment: Quantify your current stock of the reagent and calculate the "runway" based on your production forecast.

- Communicate with Stakeholders: Inform clinical teams and management of the potential risk to production timelines.

Mitigation Strategies:

- Short-Term: Contact the supplier to secure any remaining lots. Inquire about "good-neighbor" commitments where other institutions might share small quantities to bridge the gap [29].

- Long-Term:

- Supplier Qualification: Begin the process of qualifying an alternative reagent from a different vendor. This requires extensive testing to demonstrate comparability [29].

- Process Adaptation: If no direct alternative exists, investigate if the manufacturing process can be modified to eliminate the need for the reagent. This is a significant undertaking requiring regulatory approval [29].

Guide 3: Implementing a Hub and Spoke Model for a Regional Trial

Problem: A clinical trial for a new stem cell therapy needs to enroll patients from widespread, underserved regions.

Implementation Steps:

- Define Roles: Establish a central Hub (e.g., a university hospital) for complex manufacturing, long-term cryostorage, and centralized quality control. Identify several local Spokes (e.g., community clinics) for patient identification, cell collection (apheresis/biopsy), and final product infusion [30].

- Standardize Protocols: Develop and validate standardized protocols for cell collection, interim storage, and transport from the spoke to the hub. This ensures the starting material's quality is consistent regardless of the collection site [30].

- Establish Robust Logistics: Set up a reliable, monitored transport network for moving patient cells from the spoke to the hub and the finished product back to the spoke. This includes trained couriers and real-time tracking [30] [28].

Key Experimental Data and Protocols

Table 1: Cold Chain Temperature Requirements for Different Biologicals

| Product Category | Temperature Range | Primary Storage Equipment | Key Challenge |

|---|---|---|---|

| Pluripotent Stem Cells | Cryogenic (< -150°C) | Liquid Nitrogen Dewars | Risk of tumorigenesis; genetic instability during thaw [26] [28] |

| CAR-T Cell Therapies | Cryogenic or Refrigerated (2-8°C) | Liquid Nitrogen Dewars or Pharmaceutical Refrigerators | Extremely short shelf-life if refrigerated (hours/days) [28] |

| Vaccines (Standard) | Refrigerated (2-8°C) | Pharmaceutical Refrigerators | Temperature control during last-mile delivery [31] |

| Cord Blood Units | Cryogenic (< -150°C) | Liquid Nitrogen Dewars | Maintaining temperature during transport in non-disposable tanks [29] [28] |

Table 2: Research Reagent Solutions for Cell Therapy Manufacturing

| Reagent / Material | Function in Experiment | Critical Consideration |

|---|---|---|

| Hespan (HES) | Sedimentation agent for red blood cell agglutination in cord blood processing [29] | Facing industry-wide shortages; requires qualification of alternatives [29] |

| GMP-grade Cytokines | Direct cell differentiation and expansion in culture [26] | High cost; supply chain vulnerability; requires strict vendor qualification [26] |

| Cell Dissociation Agents | Detach adherent cells (e.g., stem cells) from culture surfaces [26] | Can affect cell viability and surface markers; requires validation for each cell type [26] |

| Cryopreservation Media | Protect cells during freeze-thaw cycles using DMSO and serum/serum-free alternatives [28] | DMSO can have toxic effects; formulation is critical for post-thaw viability and function [28] |

Standard Operating Procedure: Validation of a Cold Chain Shipping Container

Objective: To validate that a selected shipping container can maintain the required internal temperature range for a specified duration under simulated summer and winter conditions.

Materials:

- Shipping container (e.g., insulated shipper)

- Qualified temperature data loggers (IoT sensors preferred)

- Environmental chamber or validated cold/hot room

- Thermal mass simulant (e.g., water or gel packs)

Methodology:

- Protocol Design: Define the test parameters, including required temperature range (e.g., -175°C to -125°C), duration (e.g., 72 hours), and ambient test conditions (e.g., +40°C for summer, -20°C for winter).

- Sensor Placement: Place pre-calibrated temperature data loggers at predetermined critical locations within the empty container (e.g., geometric center, near the walls, top, and bottom).

- Thermal Load: Fill the container with a thermal mass that simulates the product load.

- Pre-conditioning: Pre-condition the container and thermal mass to the required initial transport temperature.

- Stability Testing: Place the loaded and sealed container into the pre-set environmental chamber. Start data loggers and monitor for the predefined duration.

- Data Analysis: At the end of the test period, retrieve the data and analyze it to confirm that all internal monitoring points remained within the specified temperature range for the entire duration.

Workflow Visualizations

Hub and Spoke Logistics Workflow

Temperature Excursion Response Protocol

Scalable Solutions: Implementing Advanced Bioreactor Systems and Automated Platforms

Troubleshooting Guides

Aggregation and Scalability

Problem: Excessive Aggregate Size or Inhomogeneous Aggregate Formation

- Potential Cause: Inoculation density too high or stirring speed too low.

- Solution: Optimize initial seeding density and increase agitation rate to improve hydrodynamic control. For hPSCs, single cell-based inoculation helps establish a well-controlled starting point [32].

Problem: Poor Scalability from Multi-well to Bioreactor

- Potential Cause: Differences in physical conditions (shear stress, mixing efficiency) between static and dynamic culture systems.

- Solution: Implement a scaled-up approach: first validate in rotated Erlenmeyer flasks before moving to stirred tank bioreactors. Process parameters like aggregate formation during expansion can dominate subsequent differentiation efficiency [32].

Differentiation Efficiency

Problem: Low Differentiation Efficiency in 3D vs. 2D

- Potential Cause: Cell density, aggregate size, or nutrient gradients within 3D aggregates differing from 2D monolayers.

- Solution: Systematically screen critical differentiation factors in small-scale suspension culture. For cardiac differentiation of hPSCs, performance is highly sensitive to the concentration of small molecules like CHIR99021 [32].

Problem: High Batch-to-Batch Variability

- Potential Cause: Uncontrolled process parameters and lack of real-time monitoring.

- Solution: Utilize bioreactors with integrated sensors for pH, dissolved oxygen, and metabolites. Implement controlled feeding strategies (e.g., batch or cyclic perfusion) for more consistent outcomes [33] [32].

Contamination Control

Problem: Recurring Bioreactor Contamination

- Potential Cause: Compromised sterility from inoculum, faulty seals, or inadequate sterilization.

- Solution:

- Check the inoculum: Ensure the seed train is contamination-free using plating and staining methods [34].

- Inspect bioreactor components: Regularly check and replace O-rings, valve seals, and tubing. Replace O-rings after 10-20 sterilization cycles [34].

- Validate sterilization: Use autoclave test strips or phials to confirm correct sterilization temperature and time [34].

Problem: "Hidden" Mycoplasma or Viral Contamination

- Potential Cause: Contaminants not visible via light microscopy, leading to poor cell growth.

- Solution: Use specialized test kits, PCR, or conduct regular checks for poor cell culture performance as an early indicator [34].

Frequently Asked Questions (FAQs)

Why transition from 2D flasks to 3D suspension bioreactors for PSC work? 2D cell culture is limited by surface area, manual operations, and difficulty in monitoring, making it unsuitable for large-scale production [35]. Transitioning to 3D suspension culture in bioreactors enables scalable expansion and differentiation, provides a controlled environment, and allows for the mass production of cells required for therapeutic and industrial applications [32].

What are the key process parameters to control in a stirred-tank bioreactor? Critical parameters include inoculation density, stirring speed (to control aggregate size and minimize shear stress), dissolved oxygen, pH, temperature, and feeding strategies [32]. For differentiation, the pattern of aggregate formation during the expansion phase can be a dominant factor [32].

Can I directly transfer my existing 2D differentiation protocol to a 3D bioreactor? Protocols often cannot be transferred directly and require re-optimization for 3D suspension culture. Key factors like small molecule concentrations and timing may need adjustment. It is recommended to first establish the protocol in static suspension (e.g., multi-well plates), then scale up to dynamic systems like Erlenmeyer flasks before final implementation in a stirred bioreactor [32].

How does bioreactor culture impact the quality and phenotype of the differentiated cells? Bioreactor culture conditions can influence the final cell product. For example, research has shown that culture platforms can affect the expression of key developmental signals like BMP agonists/antagonists, thereby influencing cell fate. Furthermore, stress-related markers like metallothionein may be expressed differently in bioreactor-expanded cells [32].

What are the advantages of perfusion systems? Perfusion systems allow for continuous media exchange, which helps maintain nutrient levels, remove waste products, and support higher cell densities over extended periods. This is particularly useful for sensitive cells and for processes like differentiating and maturing cells over long timeframes [33].

Experimental Protocols & Data

This protocol combines hPSC expansion as matrix-independent aggregates with cardiomyogenic differentiation using chemical Wnt pathway modulators.

Workflow Overview

1. hPSC Expansion as Aggregates

- Inoculation: Inoculate single cell-dissociated hPSCs (e.g., HES3 NKX2-5eGFP/w line) into mTeSR1 medium.

- Culture Vessel: Use stirred tank bioreactors.

- Aggregate Control: Control aggregate formation and growth by adjusting inoculation density and stirring speed.

- Feeding Strategy: Apply controlled feeding strategies such as batch or cyclic perfusion.

- Pluripotency Check: Confirm maintenance of pluripotency (e.g., >98% TRA-1-60 positive cells) before initiating differentiation.

2. Cardiomyogenic Differentiation

- Day 0: Replace mTeSR1 with differentiation medium. Add GSK3 inhibitor CHIR99021 to activate Wnt signaling. Optimal concentration is critical (e.g., 7.5 μM determined from screening).

- Day 3: Add Wnt production inhibitor IWP2 for 48 hours to inhibit Wnt pathway and specify cardiac lineage.

- Day 10 onwards: Harvest and analyze cardiomyocytes.

Quantitative Outcomes from Scaled-Up Process [32]

| Process Parameter | Multi-well Plate | Erlenmeyer Flask | 100 mL Stirred-Tank Bioreactor |

|---|---|---|---|

| Average Aggregate Size | 214 ± 65 μm | 389.4 ± 13.8 μm | Controlled by stirring |

| Optimal CHIR99021 Concentration | 7.5 μM | 7.5 μM | 7.5 μM |

| Cardiomyocyte Purity (NKX2.5-GFP+ or cTNT+) | ~52% - 60% | ~55% - >60% | Up to 85% |

| Total CM Yield per Run | Not specified | Not specified | ~40 million cells |

| Key Finding | Protocol established | Protocol transferable to dynamic culture | Production scale-up achievable; expansion pattern dictates differentiation |

The differentiation protocol relies on precise temporal modulation of the Wnt/β-catenin signaling pathway.

Research Reagent Solutions

Essential materials and reagents for implementing the described scalable PSC expansion and differentiation protocol.

| Reagent/Material | Function/Description | Example/Reference |

|---|---|---|

| mTeSR1 Medium | Defined, serum-free medium for maintenance of hPSC pluripotency in suspension culture. | [32] |

| CHIR99021 | A GSK-3 inhibitor that activates Wnt/β-catenin signaling, used for mesoderm induction at differentiation initiation. | [32] |

| IWP2 or IWR1 | Small molecule inhibitors of Wnt production/response, used after initial activation to specify cardiac lineage. | [32] |

| Bombyx mori Silk | Natural protein fiber used to fabricate porous 3D scaffolds for advanced 3D cell culture models. | [36] |

| 3D Bioreactor System | Controlled system (e.g., stirred-tank) for scalable suspension culture, allowing parameter monitoring and control. | [33] [32] |

| Nanofiber Microcarriers | Advanced microcarriers for 3D cell culture enabling high cell densities and scalability in bioreactors. | [37] |

Core Concepts: Hydrodynamic Principles in Bioreactor Design

The Critical Link Between Hydrodynamics and Cell Culture Outcomes

In stirred suspension bioreactors, the hydrodynamic environment—governed by fluid flow patterns, shear stress, and energy dissipation—directly impacts the success of stem cell cultures. For pluripotent stem cells (PSCs) grown as aggregates, this environment dictates critical quality attributes including cell viability, proliferation rates, pluripotency maintenance, and differentiation potential [38] [39]. The hydrodynamic parameters directly influence aggregate characteristics; higher shear stress and turbulent energy dissipation rates result in smaller aggregate sizes, while lower levels permit the formation of larger aggregates [40]. Controlling these parameters is essential, as excessively large aggregates (typically >300-500 μm) develop necrotic cores due to diffusion limitations of oxygen and nutrients, while overly small aggregates may exhibit reduced expansion and differentiation efficiency [40] [41].

Vertical-Wheel Technology: A Paradigm Shift in Impeller Design

The Vertical-Wheel (VW) bioreactor system incorporates an innovative impeller design that operates within a distinctive U-shaped vessel. Unlike traditional horizontal-blade impellers that create uneven hydrodynamic environments with "hot zones" of high turbulence near the impeller tips, the Vertical-Wheel generates a uniquely homogeneous distribution of hydrodynamic forces throughout the culture volume [40] [42]. The VW impeller combines radial and axial flow components, ensuring particles circulate throughout the entire bioreactor rather than becoming trapped in high-shear or low-shear zones [43]. This homogeneous environment translates to a much tighter distribution of PSC aggregate sizes, promoting consistent spherical morphology and similar diameters across the population [40] [42].

Table 1: Key Hydrodynamic Differences Between Bioreactor Impeller Types

| Hydrodynamic Characteristic | Traditional Horizontal-Blade Impeller | Vertical-Wheel Impeller |

|---|---|---|

| Flow Pattern | Predominantly axial flow | Combined radial and axial flow |

| Shear Stress Distribution | Wide variation with high-shear zones at impeller tips | Narrow, homogeneous distribution |

| Energy Dissipation Rate (EDR) Distribution | Broad range throughout vessel | Narrow distribution |

| Aggregate Size Control | Wide, heterogeneous size distribution | Tight, consistent size distribution |

| Scalability | Variable hydrodynamic environment across scales | Maintains consistent environment across scales |

Technical Support: Troubleshooting Guides and FAQs

FAQ 1: How does the Vertical-Wheel impeller achieve more uniform aggregate size distribution compared to traditional impellers?

Answer: The Vertical-Wheel impeller achieves uniform aggregate size distribution through its unique capacity to create a homogeneous hydrodynamic environment. Computational Fluid Dynamics (CFD) analysis reveals that traditional horizontal-blade impellers generate significantly uneven hydrodynamic conditions, with the highest levels of shear stress and turbulent energy dissipation rates near the rapidly spinning impeller tips, creating decreasing gradients as distance from the impeller increases [40]. This wide variation results in a broad distribution of aggregate sizes. In contrast, the Vertical-Wheel impeller, in conjunction with its U-shaped vessel, provides a consistently low shear stress profile across all impeller surfaces and maintains a narrow distribution of energy dissipation rates throughout the entire vessel [40] [42]. The fluid mixing pattern ensures all aggregates experience similar hydrodynamic conditions, resulting in a much tighter size distribution [40].

FAQ 2: What specific hydrodynamic parameters should we monitor when scaling up a PSC process from PBS-MINI to larger Vertical-Wheel bioreactors?

Answer: When scaling up PSC processes in Vertical-Wheel bioreactors, the key parameters to maintain constant are the volume-average energy dissipation rate (EDR) and maximum shear stress. Research demonstrates that keeping the volume-average EDR constant during scale-up enables maintenance of consistent aggregate sizes between different bioreactor scales [39]. CFD modeling provides precise calculations of these parameters across scales. For example, one scaling approach using Vertical-Wheel bioreactors maintained consistent hiPSC growth kinetics and aggregate sizes from 0.1L to 3L scales by applying scale-up correlations based on volume-average hydrodynamic variables [38] [43]. This method is more reliable than traditional scale-up parameters like impeller tip speed or Reynolds number, which may not adequately maintain aggregate size consistency [39].

FAQ 3: Our hiPSC aggregates are becoming too large (>400μm), leading to necrotic centers. What adjustments can we make in a Vertical-Wheel bioreactor to control aggregate size?

Answer: To reduce average aggregate size in Vertical-Wheel bioreactors, systematically increase the agitation rate within the validated operating range. Multiple studies have confirmed an inverse correlation between agitation rate and average aggregate size in Vertical-Wheel systems [40] [41]. For example:

- In PBS MINI 0.1 bioreactors (60-100mL working volume), increasing agitation from 30 rpm to higher rates (e.g., 40-60 rpm) significantly reduces average aggregate diameter [41].

- One study demonstrated that adjusting agitation rates enabled precise control of hiPSC aggregate diameters, with averages reaching 346±11 μm under optimized conditions [41].

The homogeneous hydrodynamic environment of the Vertical-Wheel ensures that increasing agitation rate uniformly reduces aggregate sizes throughout the vessel without creating a wide size distribution [40]. Additionally, consider supplementing culture media with dextran sulfate, which has been shown to reduce aggregation and increase maximum cell density by up to 106% in Vertical-Wheel bioreactors [41].

FAQ 4: We are experiencing low cell viability after inoculation in our Vertical-Wheel bioreactor. What might be causing this, and how can we optimize our inoculation protocol?

Answer: Low cell viability post-inoculation often results from suboptimal inoculation methods or hydrodynamic conditions. Implement these evidence-based solutions:

Adopt single-cell inoculation protocols: Research has established successful single-cell inoculation methods for hiPSCs in Vertical-Wheel bioreactors, achieving over 30-fold expansion in 6 days without sacrificing cell quality [38]. This approach eliminates heterogeneity associated with clump seeding.

Optimize agitation rate during early culture: Begin with lower agitation rates (e.g., 30 rpm in PBS MINI systems) to promote initial aggregate formation, then gradually increase to operational rates for complete suspension [41] [38].

Ensure proper bioreactor filling: Maintain a working volume sufficient to cover the vertical wheel (e.g., 60mL in PBS MINI 0.1) to ensure the optimized hydrodynamic profile [41].

Validate seed train quality: Cells harvested from 2D culture should be in exponential growth phase, as cells entering plateau phase may exhibit extended lag phases and varied growth kinetics in 3D culture [43].

Diagram 1: Hydrodynamic Environment Troubleshooting Guide for Common Bioreactor Challenges

Experimental Protocols & Methodologies

Protocol: hiPSC Expansion as Aggregates in PBS MINI 0.1 Bioreactor

This protocol adapts established methodologies for the expansion of human induced pluripotent stem cells as floating aggregates in Vertical-Wheel bioreactors [41] [38].

Materials:

- PBS MINI 0.1 MAG bioreactor system (PBS Biotech)

- mTeSR1 or mTeSR3D culture medium

- Dextran sulfate (optional, for enhanced yield)

- hiPSC line (e.g., TCLab, Gibco, or 4YA)

- Tris(2,2-bipyridyl) ruthenium chloride hexahydrate (for oxygen measurements)

Method:

- Bioreactor Preparation: Ensure the U-shaped vessel is properly positioned with minimal working volume of 60mL to cover the vertical wheel and ensure optimized hydrodynamic profile.

Inoculation: Use single-cell inoculation protocol established for Vertical-Wheel systems [38]:

- Harvest hiPSCs as single cells using appropriate enzymatic dissociation

- Inoculate at optimized density (protocols demonstrate success with standard densities)

- Begin with agitation rate of 30 rpm to promote initial aggregate formation

Culture Conditions:

- Maintain temperature at 37°C

- Set initial agitation rate to 30 rpm, increasing incrementally as needed to control aggregate size

- For fed-batch cultures, add concentrated medium without replacing vessel contents

- For repeated batch cultures, replace 80% of medium daily from day 2 onwards

Aggregate Monitoring:

- Monitor aggregate size daily using microscopy

- Maintain aggregate diameters between 200-400 μm through agitation adjustment

- Sample for metabolic analysis (glucose consumption, lactate production)

Harvesting: Utilize in-vessel dissociation protocol [38]:

- Apply proteolytic enzymes within the agitated bioreactor

- Control agitation exposure time to achieve single-cell harvest

- Achieve >95% recovery efficiency

Expected Outcomes:

- Maximum cell density: (2.3 ± 0.2) × 10⁶ cells∙mL⁻¹ after 5 days with mTeSR1 + dextran sulfate [41]

- Average aggregate diameter: 346 ± 11 μm under optimized conditions [41]

- Maintenance of pluripotency markers and normal karyotype [41] [38]

Protocol: Computational Fluid Dynamics Analysis for Bioreactor Optimization

CFD modeling enables detailed characterization of hydrodynamic environments without extensive empirical testing [44] [38] [39].

Software Requirements:

- OpenFOAM-8 (open source) or ANSYS Fluent (commercial)

- CAD software (e.g., AutoCAD) for geometry creation

- Meshing software (e.g., ICEM ANSYS)

Methodology:

- Geometry Creation: Develop virtual model of bioreactor vessel and impeller using CAD software.

Mesh Generation: Discretize geometry using tetrahedral elements with appropriate refinement levels.

Boundary Conditions:

- Apply wall boundary conditions to vessel wall and impeller (no-slip condition)

- Set liquid surface with free surface boundary condition (frictionless wall)

- Implement impeller rotation using moving reference frame

Solver Setup:

- Use LES-WALE turbulence modeling or k-epsilon model

- Employ SIMPLE algorithm for pressure-velocity coupling

- Set fluid properties for water at 37°C (density: 0.993 g/cm³, dynamic viscosity: 7.01 × 10⁻⁴ kg/(m·s))

Simulation Parameters:

- Run models for agitation rates between 20-100 rpm

- Ensure Courant-Friedrich-Lewy number remains below 1

- Collect volume-average values for velocity, shear stress, and energy dissipation rate

Validation: Compare simulated mass transfer coefficients with experimental spectroscopy-based oxygen measurements [44].

Table 2: Key Research Reagent Solutions for Vertical-Wheel Bioreactor Studies

| Reagent/Equipment | Function/Application | Example Usage in Protocol |

|---|---|---|

| mTeSR1/mTeSR3D Medium | Feeder-free, serum-free culture medium for hiPSCs | Expansion of hiPSCs as aggregates in VWBR [41] |

| Dextran Sulfate | Polysulfated compound reduces aggregation, increases yield | 97-106% increase in maximum cell number [41] |

| Tris(2,2-bipyridyl) ruthenium chloride | Dissolved oxygen indicator for spectroscopy | Measurement of oxygen transport coefficients [44] |

| hESC-qualified Matrigel | Feeder-free substrate for static culture expansion | Coating T-flasks for pre-bioreactor expansion [38] |

| OpenFOAM-8/ANSYS Fluent | CFD simulation software | Hydrodynamic characterization of bioreactors [44] [38] |

| Proteolytic Enzymes (Trypsin/Accutase) | Cell dissociation for harvesting | In-vessel aggregate dissociation protocol [38] |

Advanced Applications & Scaling Strategies

Scale-Up Correlations for Vertical-Wheel Bioreactors

Successful scale-up of stem cell processes requires systematic approaches to maintain consistent hydrodynamic environments across different bioreactor volumes. For Vertical-Wheel systems, CFD modeling enables development of precise scale-up correlations [43] [39]. Research demonstrates that maintaining constant volume-average energy dissipation rate (EDR) during scale-up most effectively preserves aggregate sizes and biological outcomes [39]. The stepwise approach includes:

Process Optimization at Small Scale: Optimize agitation rate for desired aggregate size and cell growth in PBS-MINI (0.1L) systems.

CFD Modeling: Develop computational models of target production scales (e.g., PBS-3, PBS-15, PBS-80).

Agitation Rate Calculation: Calculate agitation rates for larger scales that maintain constant volume-average EDR values.

Experimental Validation: Conduct limited verification runs to confirm predicted outcomes.

This approach has successfully enabled scale-up from 0.1L to 3L scales while maintaining consistent hiPSC growth kinetics, with potential for expansion to 80L production scales [40] [43].

Integration with Stem Cell Manufacturing Workflows

Vertical-Wheel bioreactor technology addresses critical bottlenecks in stem cell manufacturing, particularly for allogeneic therapies requiring large cell quantities. The technology supports: