GMP Cleanroom Classification for Cell Therapy: Standards, Implementation & Validation Guide 2024

This definitive guide for researchers, scientists, and drug development professionals explores the critical role of GMP cleanroom classification in cell therapy manufacturing.

GMP Cleanroom Classification for Cell Therapy: Standards, Implementation & Validation Guide 2024

Abstract

This definitive guide for researchers, scientists, and drug development professionals explores the critical role of GMP cleanroom classification in cell therapy manufacturing. Covering foundational ISO standards and regulatory frameworks, the article details practical methodologies for achieving and maintaining classified environments. It provides actionable troubleshooting strategies for common contamination and compliance challenges, and compares global validation approaches. The guide synthesizes key principles for ensuring product safety, efficacy, and regulatory approval in advanced therapeutic medicinal product (ATMP) production.

Understanding GMP Cleanroom Basics: ISO Standards and Regulatory Frameworks for Cell Therapy

In the field of cell therapy research, the production of Advanced Therapy Medicinal Products (ATMPs) demands an environment of unparalleled control to ensure product safety, efficacy, and consistency. Contamination, whether from particulate or microbial sources, can compromise cellular products, leading to patient risk and trial failure. The foundation of this environmental control is the cleanroom, a space with defined limits for the introduction, generation, and retention of airborne particulates. The international standard ISO 14644-1, "Classification of air cleanliness by particle concentration," provides the definitive framework for classifying these critical environments. This guide details the ISO 14644-1 classes (specifically A, B, C, and D as adopted by GMP) and their profound significance in the context of Good Manufacturing Practice (GMP) for cell therapy research and drug development.

ISO 14644-1 Classification System: Core Principles

ISO 14644-1 classifies cleanrooms based on the concentration of airborne particles equal to and larger than a specified size (e.g., ≥0.5 µm). The classification is designated by an "ISO Class" number, where a lower number signifies a cleaner environment (fewer allowable particles). The standard outlines statistical methods for sampling and testing to verify compliance. For GMP applications, particularly in sterile manufacturing for pharmaceuticals and biologics, the European Union GMP Annex 1 and other regulatory documents map these ISO classes to grades (A, B, C, D) for operational clarity.

Detailed Class Specifications & GMP Correlation

The following table summarizes the maximum permitted particle concentrations per cubic meter for key ISO classes and their corresponding GMP grades, which are critical for cell therapy operations.

Table 1: ISO 14644-1 Particle Concentration Limits and GMP Grade Equivalents

| ISO 14644-1 Class | ≥0.5 µm particles / m³ | ≥5.0 µm particles / m³ | Equivalent EU GMP Grade (Operational State) | Typical Applications in Cell Therapy |

|---|---|---|---|---|

| ISO 5 | 3,520 | 29 | Grade A | Critical processing zone (e.g., cell manipulation, filling, open connections). |

| ISO 7 | 352,000 | 2,930 | Grade B | Background environment for a Grade A zone (e.g., cleanroom suite for aseptic processing). |

| ISO 8 | 3,520,000 | 29,300 | Grade C | Preparation of less critical solutions, background for Grade A/B areas, gowning. |

| ISO 9 | 35,200,000 | 293,000 | Grade D | Component and material staging, basic background for cleaner areas. |

Note: Limits are derived from the formula: *particle concentration = 10^N × (0.1/D)^2.08, where N is the ISO class number and D is the particle size in µm. The GMP grades (A-D) define not only particle limits but also microbial action levels and operational conditions (at-rest, in-operation).*

Experimental Protocol: Cleanroom Classification Testing (ISO 14644-1)

The verification of a cleanroom's ISO class requires a standardized testing protocol. Below is the core methodology.

4.1. Objective: To determine the concentration of airborne particles in a cleanroom or clean zone and verify compliance with the specified ISO class.

4.2. Key Equipment & Materials (The Scientist's Toolkit):

Table 2: Key Research Reagent Solutions & Materials for Classification Testing

| Item | Function |

|---|---|

| Discrete Particle Counter (DPC) | Primary instrument for sampling and sizing airborne particles. Must be calibrated and have a suitable flow rate (e.g., 1 CFM or 28.3 L/min). |

| Isopropyl Alcohol (IPA), 70% | Used for cleaning sampling probes and external surfaces of the DPC before entering the cleanroom. |

| Particle-Free Wipes | For general cleaning of equipment and surfaces to prevent sample contamination. |

| Validation Kit (Optional) | Aerosolizer and certified reference particles (e.g., polystyrene latex spheres) for challenging the DPC for performance checks. |

| Sampling Probe & Tubing | Connects the DPC intake to the specific location being sampled. Must be particle-shedding resistant and of appropriate length. |

| Tripod & Adjustable Arm | To position the sampling probe at the correct, stable height for testing. |

4.3. Methodology:

- Preparation: Clean the DPC and sampling accessories with IPA wipes outside the cleanroom. Allow the DPC to complete its self-check and zero-count procedure.

- Determine Sampling Locations: Calculate the minimum number of sampling locations (Nₗ) using the formula: Nₗ = √A, where A is the area of the cleanroom in m². Distribute locations evenly across the room.

- Set Test Parameters: Program the DPC with the relevant particle size thresholds (e.g., 0.5 µm and 5.0 µm).

- Perform Particle Counting: At each location, position the sampling probe at the specified work height (e.g., 0.8-1.2 m). Take a sample volume of air sufficient to count at least 20 particles for the target size. Per ISO, the minimum single sample volume is 1 liter for ISO 5, and 2 liters for others.

- Data Analysis: For each location, calculate the average particle concentration per cubic meter for each particle size. Calculate the overall mean and 95% upper confidence limit (UCL) from all locations. The cleanroom meets the classification if the UCL is at or below the class limit.

Significance in Cell Therapy GMP

The classification is not an end in itself but a cornerstone of contamination control strategy (CCS). For cell therapies:

- Grade A/ISO 5: Mandatory for all aseptic handling of open product containers. Protects the sterile product directly from particulate and microbial contamination.

- Grade B/ISO 7: Provides a controlled background that protects the Grade A zone from adjacent areas, ensuring its performance.

- Grades C & D/ISO 8 & 9: Serve as progressively less critical buffers, controlling the flow of personnel, materials, and air to prevent ingress of contamination into higher-grade areas.

This cascading pressure and classification system is fundamental to managing the inherent risks of aseptic processing for products that cannot be terminally sterilized, such as living cell therapies.

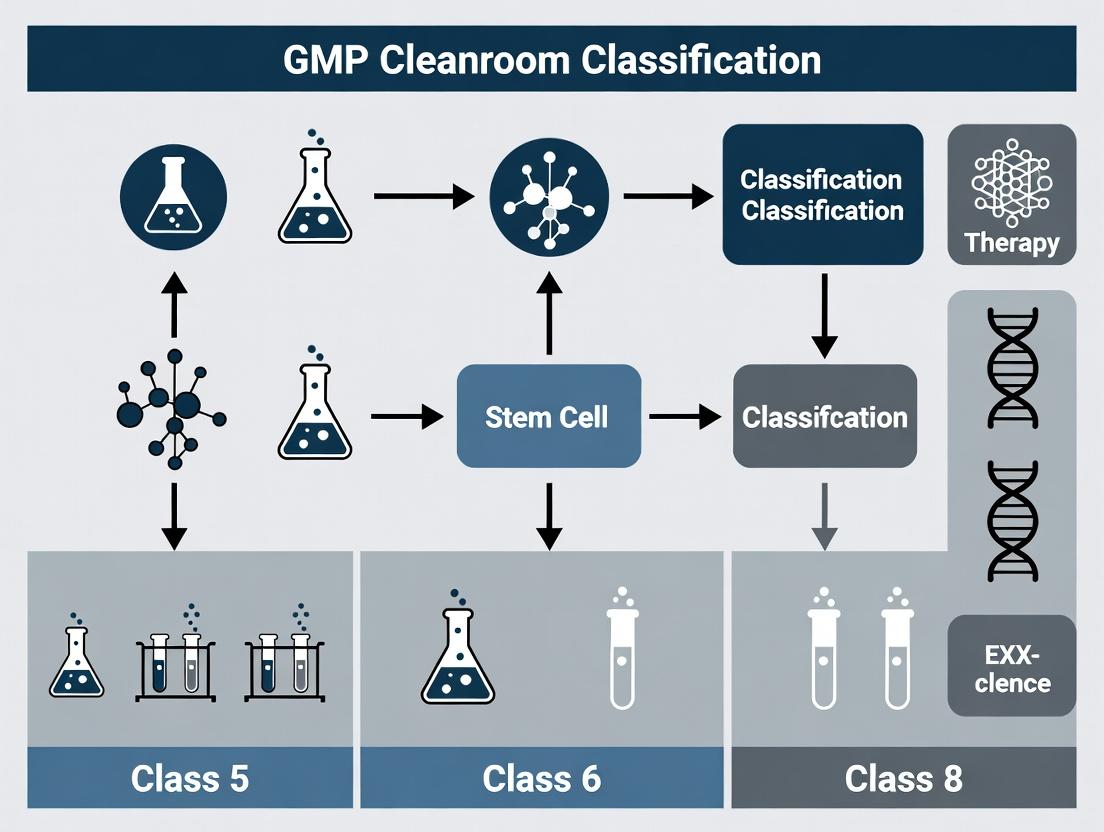

Logical Relationship: From Classification to Contamination Control

The following diagram illustrates the logical flow from the core ISO classification standard to the ultimate goal of patient safety in cell therapy.

Diagram 1: Cleanroom Class to Product Safety Flow

The ISO 14644-1 classification system, as enacted through GMP grades A-D, provides the quantitative, science-based backbone for designing, verifying, and operating cleanrooms for cell therapy research and manufacturing. Understanding the specific particle limits, testing methodologies, and operational significance of each class is non-negotiable for scientists and professionals developing these life-changing therapies. It ensures that the controlled environment is a reliable tool—not a variable—in the quest for consistent, safe, and efficacious advanced medicinal products.

Why Cleanroom Classification is Non-Negotiable for Cell Therapy Product Safety and Efficacy

In the advanced therapeutic medicinal product (ATMP) landscape, cell therapies represent a paradigm shift in treating degenerative and oncological diseases. The intrinsic biological nature of these products—living cells—renders them uniquely vulnerable to contamination and environmental stressors. Unlike traditional pharmaceuticals, they cannot undergo terminal sterilization. Consequently, their safety and efficacy are irrevocably tied to the aseptic conditions of their manufacturing environment. This whitepaper establishes cleanroom classification, as defined by ISO 14644 and EU GMP Annex 1, as the foundational pillar of Current Good Manufacturing Practice (cGMP) for cell therapy. It argues that rigorous classification is non-negotiable for controlling critical parameters like airborne particulate and microbial contamination, directly impacting product purity, patient safety, and regulatory approval.

The Science of Contamination Risk in Cell Therapy

Cell therapy products, including chimeric antigen receptor T-cells (CAR-T) and mesenchymal stem cells (MSCs), are cultured over days or weeks, providing an extended window for contamination. Microbial ingress (bacteria, fungi, mycoplasma) can outcompete or toxify cell cultures, while non-viable particulates can introduce endotoxins or act as carriers for viable contaminants. Most critically, a single contaminant introduced during manufacturing can proliferate to dangerous levels in the final infusion bag, posing severe risks of sepsis or death to the immunocompromised recipient.

Table 1: Impact of Environmental Contaminants on Cell Therapy Products

| Contaminant Type | Direct Impact on Product | Risk to Patient |

|---|---|---|

| Bacteria | Culture overgrowth, nutrient depletion, toxin release. | Sepsis, endotoxic shock. |

| Fungi/Molds | Mycotoxin production, hyphal overgrowth. | Systemic fungal infection. |

| Mycoplasma | Alters cell metabolism, function, and viability; difficult to detect. | Immune modulation, unclear pathological consequences. |

| Endotoxins (from Gram- bacteria) | Binds to cell surfaces, induces inflammatory cytokine release, alters cell phenotype. | Pyrogenic reaction, multi-organ failure. |

| Airborne Particles | Acts as carrier for viable contaminants, introduces foreign materials. | Immune reactions, granuloma formation. |

Cleanroom Classification Standards: ISO and GMP

Cleanroom classification provides a quantifiable framework for contamination control. ISO 14644-1 defines classes based on the maximum allowable concentration of airborne particles of specified sizes. EU GMP Annex 1 (2022) integrates these with additional, stricter requirements for aseptic manufacturing, including microbial monitoring grades (A, B, C, D).

Table 2: Key Cleanroom Class Limits for Aseptic Processing (ISO 14644-1 & EU GMP Annex 1)

| ISO Class | GMP Grade | ≥0.5 µm particles/m³ | ≥5.0 µm particles/m³ | Typical Operations for Cell Therapy |

|---|---|---|---|---|

| ISO 5 | A | 3,520 | 20 | Critical open manipulations (e.g., vial thaw, vector addition, final fill) within a unidirectional airflow cabinet (UDAF) or isolator. |

| ISO 5 | B | 3,520 | 20 | Background environment for a Grade A zone. Gowning for entry into Grade A/B areas. |

| ISO 7 | C | 352,000 | 2,930 | Less-critical closed processing steps (e.g., closed-system centrifugation, incubation). |

| ISO 8 | D | 3,520,000 | 29,300 | Background for Grade C areas. Non-critical support areas. |

Experimental Protocol: Environmental Monitoring (EM) for Classification & Control

Verification and ongoing monitoring of cleanroom classification are mandated. The following protocol details a standard particle count and microbial air sampling procedure.

Protocol: Routine Non-Viable and Viable Particle Monitoring in a Grade B (ISO 5) Cleanroom

Objective: To verify the airborne particulate and microbial counts comply with ISO 5 / Grade B limits at the point of use during simulated critical processing.

Materials: (See Scientist's Toolkit) Method:

- Pre-Sampling: Decontaminate all monitoring equipment with sterile 70% IPA and allow to dry. Transport to the sampling location (e.g., beside the open processing area of a biosafety cabinet).

- Non-Viable Particle Counting:

- Place the airborne particle counter probe at the designated sample location, 9-12 inches from the critical site.

- Set the counter to sample a minimum volume of 1 cubic meter per location as per ISO 14644-1.

- Initiate sampling for the required duration. Record the cumulative counts for particles ≥0.5µm and ≥5.0µm.

- Repeat sampling at a minimum of 3-5 locations within the room/zone.

- Viable Air Monitoring (Active Air Sampling):

- Load a sterile contact plate containing appropriate agar (e.g., TSA for bacteria, SDA for fungi) into the air sampler.

- Position the sampler inlet at the same critical location.

- Set the sampler to draw a calibrated volume of air (typically 1 cubic meter) over the plate.

- After sampling, seal and label the plate. Incubate TSA at 30-35°C for 3-5 days and SDA at 20-25°C for 5-7 days.

- Count resulting colony-forming units (CFUs).

- Data Analysis: Compare average particle counts and CFU results against the alert and action limits derived from ISO and GMP standards. Any excursion triggers an investigation and corrective action.

Title: Cleanroom Environmental Monitoring Workflow

The Scientist's Toolkit: Essential Reagents & Materials for EM

Table 3: Key Research Reagent Solutions for Cleanroom Monitoring

| Item | Function / Role in EM |

|---|---|

| Airborne Particle Counter | Measures the concentration of non-viable airborne particles (≥0.5µm, ≥5.0µm) to verify ISO classification compliance. |

| Active Air Sampler | Draws a calibrated volume of air onto a microbial growth medium for quantifiable CFU analysis. |

| Tryptic Soy Agar (TSA) Plates | General-purpose growth medium for detecting a wide spectrum of bacteria and fungi. |

| Sabouraud Dextrose Agar (SDA) Plates | Selective medium optimized for detecting yeasts and molds. |

| 70% Isopropyl Alcohol (IPA) | Standard cleanroom disinfectant for decontaminating equipment and surfaces prior to monitoring. |

| Contact Plates (RODAC) | For surface microbial monitoring on equipment and operator gloves. Contains neutralizing agents. |

| Particulate Matter Standards | Calibration standards (e.g., polystyrene latex spheres) for verifying particle counter accuracy. |

The Logical Chain: From Classification to Product Success

Cleanroom classification is not an isolated compliance exercise but the first link in a causal chain determining product success. It is the primary engineering control that enables all subsequent process controls to be effective.

Title: Cleanroom Impact on Cell Therapy Success

For cell therapy, the manufacturing environment is an extension of the product itself. Cleanroom classification provides the essential, quantifiable standard for that environment. It is the non-negotiable prerequisite that bridges the gap between promising preclinical science and a safe, effective, and commercially viable clinical product. Investing in rigorous classification, monitoring, and control is ultimately an investment in patient safety and the future of the therapy.

This technical guide examines the key regulatory drivers for Advanced Therapy Medicinal Product (ATMP) manufacturing, with a specific focus on cleanroom classification requirements. Framed within a broader thesis on GMP cleanroom standards for cell therapy research, it provides a comparative analysis of guidelines from the U.S. Food and Drug Administration (FDA), the European Medicines Agency (EMA), and the Pharmaceutical Inspection Co-operation Scheme (PIC/S). The convergence and divergence in these regulatory approaches directly impact facility design, environmental monitoring, and contamination control strategies essential for autologous and allogeneic cell therapy production.

Regulatory Landscape: Comparative Analysis

The following table summarizes the core regulatory documents and their primary focus concerning ATMP manufacturing environments.

| Regulatory Body | Key Guideline / Directive | Title / Reference | Primary Focus for ATMP Manufacturing |

|---|---|---|---|

| FDA (U.S.) | 21 CFR Parts 210, 211, 1271 | Current Good Manufacturing Practice | Integrated approach for drugs and HCT/Ps. Emphasis on prevention of contamination, cross-contamination. Risk-based controls. |

| FDA (U.S.) | Guidance for Industry (2020) | Sterile Drug Products Produced by Aseptic Processing | Aseptic processing fundamentals, cleanroom classification (ISO equivalent), monitoring. Core reference for environmental standards. |

| EMA (EU) | Regulation (EC) No 1394/2007, Directive 2001/83/EC | Advanced Therapy Medicinal Products | Legal framework for ATMPs. Requires GMP compliance per EudraLex Volume 4. Specific considerations for patient-specific products. |

| EMA (EU) | EudraLex Volume 4, Annex 1 (2022) | Manufacture of Sterile Medicinal Products | Legally enforceable GMP. Detailed cleanroom classification (A/B/C/D), contamination control strategy (CCS), isolator/RABS guidance. |

| PIC/S (International) | PI 007-6 (2021) | Recommendation on the Validation of Aseptic Processes | Harmonized guide for aseptic processes. Cleanroom classification aligned with ISO 14644-1 and EU GMP. Promotes global harmonization. |

| PIC/S (International) | PI 045-1 (2022) | Guidance on ATMPs GMP | Dedicated ATMP GMP guide. Flexible, risk-based approach to cleanroom standards, especially for open steps in autologous therapies. |

Quantitative Cleanroom Classification Standards

Cleanroom classification based on airborne particulate concentration is a foundational requirement. The following table compares the maximum permitted particle counts per cubic meter (≥0.5 μm) for each grade/class.

| Grade / Class (EU GMP / ISO) | At Rest (≥0.5 μm particles/m³) | In Operation (≥0.5 μm particles/m³) | Typical Application in ATMPs |

|---|---|---|---|

| Grade A (ISO 5) | 3,520 | 3,520 | Critical aseptic operations (e.g., vial filling, open manipulation of cells). |

| Grade B (ISO 7) | 3,520 | 352,000 | Background environment for Grade A zones (e.g., cleanroom housing a closed isolator). |

| Grade C (ISO 8) | 352,000 | 3,520,000 | Preparation of less critical solutions, background for closed processing steps. |

| Grade D (ISO 8) | 3,520,000 | Not formally defined | Gowning, background for non-critical processing steps. |

Note: FDA aseptic guidance references ISO 14644-1 standards (ISO 5, 7, 8), which are numerically aligned with the "in operation" limits above. EMA Annex 1 (2022) formally adopts the ISO nomenclature alongside Grades A-D.

Experimental Protocol: Viable Environmental Monitoring (EM) for Grade A Zones

A robust EM program is mandated to demonstrate continuous control of the aseptic core.

Title: Settle Plate Exposure for Viable Airborne Contamination Monitoring in a Grade A Laminar Airflow Hood.

Objective: To actively monitor the prevalence of viable, settling microorganisms in a Grade A zone during a simulated cell thawing and feeding operation.

Materials & Equipment:

- Pre-poured Tryptic Soy Agar (TSA) settle plates (90mm diameter).

- Incubator (set at 20-25°C for fungal growth and 30-35°C for bacterial growth).

- Ethanol (70%) and sterile wipes for plate decontamination.

- Timer.

- GMP Grade A zone (Laminar Airflow Hood/Workbench).

Methodology:

- Preparation: Decontaminate the external surface of the settle plate containers with 70% ethanol and allow them to dry. Perform the experiment during a simulated production run ("in operation").

- Placement: Remove the lid from a settle plate. Place the open plate at a predetermined, risk-assessed location within the Grade A zone where product or open containers are exposed (e.g., next to the processing rack). Ensure the plate does not obstruct airflow or the critical process.

- Exposure: Expose the plate for the duration of the critical open step (e.g., 4 hours), as defined in the CCS. Record the start and end times.

- Recovery & Incubation: After exposure, replace the lid. Collect the plate and incubate it according to a dual-incubation regimen:

- First at 30-35°C for 48-72 hours to promote bacterial growth.

- Then at 20-25°C for a further 72-96 hours to promote fungal growth.

- Analysis: Count all colony-forming units (CFUs) after each incubation phase. The acceptance criterion for Grade A per EMA Annex 1 is <1 CFU per plate for a 4-hour exposure. Any deviation must be investigated as a potential breach of aseptic conditions.

- Documentation: Record all data, including plate location, exposure time, incubator details, CFU counts, and any identification of recovered organisms.

The Scientist's Toolkit: Key Reagent Solutions for Process Validation

Essential materials for conducting sterility assurance and process validation studies in ATMP cleanrooms.

| Item / Reagent | Function / Purpose in Context |

|---|---|

| Tryptic Soy Agar (TSA) Plates | General-purpose growth medium for environmental monitoring (settle plates, contact plates, air samplers) to capture a broad spectrum of viable bacteria and fungi. |

| Sabouraud Dextrose Agar (SDA) Plates | Selective medium optimized for isolating and enumerating fungi and yeasts, used as a complementary method to TSA in EM programs. |

| LAL (Limulus Amebocyte Lysate) Reagent | Detect and quantify bacterial endotoxins (pyrogens) in final product samples or critical process water (WFI). Essential for product safety testing. |

| Cell Culture Media (Serum-free, GMP-grade) | Defined, xeno-free formulation for the expansion of therapeutic cells. Minimizes contamination risk and supports regulatory compliance. |

| Process Residual Detection Kits (e.g., for antibiotics, cytokines) | ELISA or PCR-based kits to quantify the clearance of process residuals (like induction agents) during manufacturing, demonstrating process robustness. |

| Mycoplasma Detection Kit (PCR-based) | Rapid, highly sensitive method to test master/working cell banks, harvests, and final products for Mycoplasma contamination, a critical quality attribute. |

| Closed System Processing Assemblies (Tubes, Connectors) | Sterile, functionally closed fluid pathways that maintain asepsis, reducing the classification requirement for the surrounding environment per risk-based guidelines. |

Visualizing the Contamination Control Strategy (CCS) Logic

A holistic CCS is mandated by EMA Annex 1 and expected by FDA and PIC/S.

Title: ATMP Contamination Control Strategy Logic Flow

Visualizing a Risk-Based Aseptic Processing Workflow

Decision-making for environmental controls based on process closure.

Title: Risk-Based Aseptic Processing Decision Tree

The regulatory landscape for ATMP cleanroom manufacturing is defined by the detailed, legally binding requirements of EMA Annex 1, the risk-based framework of the FDA, and the harmonization efforts of PIC/S. A successful compliance strategy hinges on implementing a dynamic, science- and risk-based Contamination Control Strategy (CCS). This CCS must integrate qualified facility design (leveraging ISO 5-8/Grade A-D classifications), validated closed systems where possible, rigorous environmental monitoring, and robust process validation (media fills). For researchers, understanding these interlocking drivers is critical to designing facilities and processes that ensure patient safety, product quality, and regulatory approval across major global markets.

Within the context of Good Manufacturing Practice (GMP) cleanroom classification for cell therapy research, environmental control is non-negotiable. The efficacy and safety of cell-based therapeutics are intrinsically linked to the environment in which they are manufactured. This technical guide details the critical parameters of non-viable particle counts, viable microbial limits, and the essentials of a robust environmental monitoring (EM) program, which together form the cornerstone of contamination control strategies essential for aseptic processing.

Particle Counts: The Foundation of Cleanroom Classification

Non-viable particle monitoring provides the primary data for cleanroom classification per ISO 14644-1 and EU GMP Annex 1. For cell therapy, where products are often minimally manipulated and cannot be terminally sterilized, controlling particulate matter is critical to prevent pyrogenic reactions, physical occlusion upon administration, and potential vector contamination.

Classification Limits and Measurement Protocol

Cleanroom classification is based on the concentration of airborne particles equal to and larger than 0.5 µm and 5.0 µm. The following table summarizes the maximum permitted concentrations for key classifications relevant to cell therapy.

Table 1: ISO 14644-1 Cleanroom Classification Limits (particles/m³ of air)

| ISO Class | ≥0.5 µm Particles | ≥5.0 µm Particles | Typical Application in Cell Therapy |

|---|---|---|---|

| ISO 5 (Class 100) | 3,520 | 29 | Critical processing (e.g., vial filling, open manipulations) within a Grade A zone. |

| ISO 7 (Class 10,000) | 352,000 | 2,930 | Background environment for Grade B aseptic preparation and filling areas. |

| ISO 8 (Class 100,000) | 3,520,000 | 29,300 | Background for Grade C areas (e.g., solution preparation, wash rooms). |

Protocol for Particle Counting:

- Instrument Calibration: Use a calibrated airborne particle counter with a suitable sample flow rate (e.g., 1 cfm or 28.3 L/min).

- Sample Volume & Locations: Determine minimum sample volume per location as per ISO 14644-1. For certification, sample locations are based on the area of the cleanroom. For routine monitoring, place samplers at sites representing worst-case conditions (e.g., near operator, product exposure points).

- Sampling Method: Conduct sampling with the cleanroom in the "at-rest" state (equipment running, no personnel) for classification, and in the "operational" state for routine monitoring.

- Data Analysis: Compare the average concentration at each location to the class limit. The room meets the classification if all locations comply.

Microbial Limits: Controlling Viable Contaminants

Microbial monitoring assesses the bioburden from personnel, materials, and equipment. For cell therapies, microbial contamination can lead to product loss, patient infection, and compromised therapeutic efficacy.

Action and Alert Limits

Microbiological monitoring employs both alert (warning level) and action (investigation/remediation level) limits. Limits are typically established based on historical data, regulatory guidance, and process capability.

Table 2: Example Microbial Monitoring Limits for Different Cleanroom Grades

| Grade | Air Sample (CFU/m³) | Settle Plates (Ø90mm, 4hr, CFU) | Surface Contact (Ø55mm, CFU/plate) | Glove Print (CFU/glove) |

|---|---|---|---|---|

| A | <1 | <1 | <1 | <1 |

| B | 10 | 5 | 5 | 5 |

| C | 100 | 50 | 25 | - |

| D | 200 | 100 | 50 | - |

CFU: Colony Forming Unit

Experimental Protocols for Viable Monitoring

Protocol for Active Air Sampling:

- Use a calibrated volumetric air sampler (e.g., slit-to-agar or centrifugal).

- Load with appropriate growth media (e.g., Tryptic Soy Agar for total aerobic count).

- Sample a defined volume (typically 1 m³) at critical locations.

- Incubate plates: 20-25°C for 5-7 days (fungi) and 30-35°C for 3-5 days (bacteria).

- Count CFUs and identify isolates to species level following aberrant results.

Protocol for Surface Monitoring (Contact Plates):

- Use pre-filled contact plates with neutralizing agar (e.g., D/E Neutralizing Agar) for disinfectant residue neutralization.

- Press the agar surface evenly against a flat test surface for ~5 seconds.

- Cover and incubate as above.

- Report results as CFU/plate.

Environmental Monitoring Program Essentials

An EM program is a holistic system integrating particle, microbial, and physical parameter data to ensure continuous environmental control.

Key Components of an EM Program

- Risk-Based Site Selection: Locations based on a risk assessment (e.g., product exposure points, high-activity areas, transfer routes).

- Frequency and Sample Volume: Defined based on process criticality, historical data, and classification.

- Data Management and Trend Analysis: Use statistical process control to identify adverse trends before action limits are breached.

- Incident Investigation: A clear procedure for out-of-specification (OOS) and out-of-trend (OOT) results, including impact assessment on product quality and corrective actions.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials for Environmental Monitoring

| Item | Function |

|---|---|

| Particle Counter | Measures and sizes non-viable airborne particles for cleanroom classification and routine monitoring. |

| Volumetric Air Sampler | Actively draws a known volume of air onto growth media for quantitative assessment of airborne microbial load. |

| Settle Plates | Passive monitoring method using open agar plates to assess fallout of viable particles over time. |

| Contact Plates (RODAC) | Contain solid culture media with a raised agar surface for sampling flat surfaces for microbial contamination. |

| Tryptic Soy Agar (TSA) | General-purpose growth medium for the cultivation of a wide variety of bacteria and fungi. |

| Sabouraud Dextrose Agar (SDA) | Selective medium optimized for the isolation and cultivation of fungi and yeasts. |

| D/E Neutralizing Agar | Contains neutralizers (e.g., lecithin, polysorbate) to inactivate residual disinfectants on sampled surfaces. |

| Incubators (Dual-Temp) | Required for incubation at both 20-25°C (mold recovery) and 30-35°C (bacteria recovery). |

| Microbial Identification System | Used for spectral, biochemical, or genetic identification of microbial isolates from EM. |

Visualization of Core Concepts

Diagram 1: GMP EM Decision Pathway

Diagram 2: EM Site Selection Workflow

The Direct Link Between Air Quality, Aseptic Processing, and Final Product Viability

Abstract: This technical guide elucidates the causal chain linking cleanroom air quality, aseptic processing integrity, and the viability of cell therapy products. Framed within a thesis on Good Manufacturing Practice (GMP) cleanroom classification, we present a data-driven analysis of how airborne particle and microbial counts directly influence process contamination rates and critical quality attributes of the final cellular drug product.

In advanced therapeutic medicinal product (ATMP) manufacturing, the production environment is a direct critical process parameter (CPP). The classification of a cleanroom (ISO 14644-1 / EU GMP Annex 1) defines the permissible concentrations of airborne particulates, which serve as vectors for microbial contamination. This establishes an unbreakable link between the measured air quality, the ability to execute processes aseptically, and the purity, potency, and viability of the final cell therapy.

Quantitative Foundations: Air Quality Standards and Measured Outcomes

Table 1: Cleanroom Classification Limits (ISO 14644-1:2015) and Associated Microbial Risk

| ISO Class | ≥0.5 µm particles/m³ | ≥5.0 µm particles/m³ | Typical Microbial Action Limit (CFU/m³) | Recommended Process for Cell Therapies |

|---|---|---|---|---|

| ISO 5 (Grade A) | 3,520 | 20 | <1 | Final product formulation, filling, open manipulations |

| ISO 7 (Grade B) | 352,000 | 2,930 | 10 | Background for ISO 5 zone, critical processing steps |

| ISO 8 (Grade C) | 3,520,000 | 29,300 | 100 | Less critical processing steps, buffer preparation |

Table 2: Correlation Between In-Process Air Quality Deviations and Product Impact

| Contaminant Type | Threshold Deviation | Observed Impact on Cell Product (from cited studies) | Corrective Action Required |

|---|---|---|---|

| Viable Airborne (CFU) | > Action Limit in Grade A | Increased probability of sterility test failure; potential for endotoxin/pyrogen presence | Halt process, investigate source, decontaminate, assess product impact. |

| Non-Viable Particles (≥0.5µm) | > ISO Class limit for 5 min | Direct physical incorporation into product; risk of immunogenic response in patient. | Review gowning, material flow, equipment. Filter integrity test. |

| Specific Organism | Detection of Staphylococcus spp., Bacillus spp. | Indicator of human shedding or environmental ingress. Compromised aseptic technique. | Review personnel practices and material transfer procedures. |

Experimental Protocols for Validating the Link

Protocol 1: Concurrent Monitoring of Viable Particles and Process Contamination

Objective: To statistically correlate real-time airborne microbial counts with contamination rates in media exchanges. Materials: Active viable air sampler (e.g., slit-to-agar or centrifugal), particle counter, sterile cell culture media, T-flasks. Method:

- Place active air sampler and particle counter within 1 ft of the open processing area (e.g., biosafety cabinet).

- Perform 30 identical media exchange operations on seeded cell culture flasks under normal conditions.

- For each operation, run the air sampler for the duration of the open manipulation (typically 5-10 minutes). Record particle counts.

- After media exchange, incubate the processed cell cultures for 14 days at 32.5°C, observing for turbidity (microbial growth).

- Culture the air sampler plates at 20-25°C for 5-7 days and 30-35°C for 2-3 days. Count CFUs.

- Perform regression analysis comparing CFU/m³ during each manipulation with the sterility outcome of the corresponding culture flask.

Protocol 2: Assessing Product Viability Impact from Particle Ingress

Objective: To measure the effect of introduced non-viable particles on critical quality attributes (CQAs) like cell viability and function. Materials: Standardized latex spheres (0.5µm, 5µm), flow cytometer, cell viability assay (e.g., Annexin V/PI), functional assay (e.g., cytokine secretion ELISpot). Method:

- Culture therapeutic T-cells under ISO 5 conditions to 80% confluence.

- Divide cells into three groups: Control (no particles), Low Particle (10 particles/cell), High Particle (100 particles/cell). Introduce particles during a simulated "open" step.

- Incubate cells for 24 hours post-exposure.

- Analyze:

- Viability: Use flow cytometry with Annexin V/PI staining.

- Apoptosis/Necrosis: Caspase-3/7 activity assay.

- Function: Stimulate cells with antigen-presenting cells; measure IFN-γ secretion via ELISpot.

- Compare CQAs between groups using ANOVA; establish a dose-response relationship between particle load and functional attenuation.

Visualizing the Contaminant Pathway and Control Strategy

Title: Contaminant Pathway from Air to Cell Therapy Product

Title: CPP-CQA Link: Air & Asepsis to Product Viability

The Scientist's Toolkit: Essential Reagent Solutions

| Research Reagent / Material | Primary Function in Air Quality/Viability Studies |

|---|---|

| Tryptic Soy Agar (TSA) Plates | For active air sampling; supports growth of aerobic mesophilic bacteria and fungi for viable particle counting. |

| Sabouraud Dextrose Agar (SDA) Plates | Selective for yeasts and molds; used for comprehensive environmental monitoring (EM) in humid processing steps. |

| Latex Microsphere Standards (0.5µm, 5.0µm) | Calibration and challenge particles for optical particle counters and for spiking studies to assess product impact. |

| Annexin V / Propidium Iodide (PI) Kit | Flow cytometry-based assay to quantify early apoptosis (Annexin V+) and late apoptosis/necrosis (PI+) in cells post-particle exposure. |

| LAL Endotoxin Assay Kit | Quantifies bacterial endotoxins (from Gram-negative bacteria) that can be introduced via air/particles and cause pyrogenic responses. |

| ATP Surface Swabs & Luminometer | Rapid hygiene monitoring of surfaces and gloves to prevent indirect contamination transfer; correlates with aseptic technique quality. |

| Closed System Processing Assemblies | Pre-sterilized, welded tubing and connectors that eliminate open manipulations, directly decoupling the process from air quality. |

| Real-Time Particle Counter with Data Logging | Provides continuous ISO classification verification and trend analysis to identify process events that generate particles. |

The viability and success of a cell therapy product are irrevocably determined by the air quality in which it is processed and the robustness of the aseptic techniques employed. Cleanroom classification is not a bureaucratic exercise but a foundational scientific control. By rigorously monitoring air quality parameters as CPPs and understanding their mechanistic link to CQAs, researchers and drug developers can design processes that inherently protect product viability, ensuring both patient safety and therapeutic efficacy.

Implementing and Maintaining a Compliant Cleanroom: A Step-by-Step Operational Guide

Within the broader thesis on GMP cleanroom classification for cell therapy research, the physical facility design is paramount for ensuring product safety, efficacy, and regulatory compliance. This whitepaper provides an in-depth technical guide to three foundational design principles: zoning, airlocks, and pressure cascades. These elements collectively control contamination and cross-contamination risks inherent in manufacturing advanced therapy medicinal products (ATMPs).

Facility Zoning Strategy

Zoning segregates operations based on criticality and contamination risk. A unidirectional flow of personnel, materials, and product is enforced to protect the aseptic core.

Table 1: Typical Cleanroom Classification & Zoning for Cell Therapy

| Zone / Room Function | Target ISO Class (ISO 14644-1) | Equivalent EU GMP Grade (Annex 1) | Primary Contamination Control Rationale |

|---|---|---|---|

| Cell Expansion & Manipulation | ISO 5 | Grade A | Direct open processing of product; highest protection required. |

| Background to Grade A Area | ISO 7 | Grade B | Provides a protected environment for the Grade A zone. |

| Critical Raw Material Prep (e.g., media) | ISO 7 | Grade B | Prevents introduction of contaminants into product contact materials. |

| Non-Viral Vector Production | ISO 7 | Grade B | Controlled environment for biological agents. |

| Viral Vector Production (Contained) | ISO 7 with negative pressure | Grade B (Contained) | Physical containment of genetically modified organisms. |

| Fill/Finish | ISO 5 (with ISO 7 background) | Grade A (with Grade B background) | Aseptic filling of final product. |

| QC Laboratories (e.g., sterility) | ISO 7 | Grade B | Testing requires aseptic conditions. |

| Warehouse & Quarantine | Unclassified | Unclassified | Storage with separation of released and non-released materials. |

Airlock Design and Function

Airlocks are transitional spaces that separate zones of different cleanliness classes. They use interlocks to prevent simultaneous door opening, allowing for controlled decontamination procedures.

Types and Protocols:

Personnel Airlocks (PAL): Used for gowning.

- Protocol: An individual enters from a corridor (ISO 8/unclassified) into the PAL. The outer door closes and locks. The individual performs a defined gowning sequence (e.g., don sterile gloves, hair cover, face mask, and gown). A visual indicator signals when it is safe to open the inner door into the higher-grade zone (e.g., ISO 7).

Material Airlocks (MAL): Used for transferring equipment and supplies.

- Protocol (Double-Door Autoclave/Pass-Through): Materials are loaded from the lower-grade side. The autoclave cycle (e.g., 121°C, 20 minutes) or vaporized hydrogen peroxide (VHP) decontamination cycle is initiated. Once cycle parameters are met and verified, the inner door can be unlocked from the clean side for retrieval.

- Protocol (Dynamic MAL with VHP): Materials are placed on racks, the outer door seals, a VHP cycle decontaminates the chamber and materials' surfaces, an aeration phase removes residual VHP, and then the inner door is unlocked.

Sample Airlocks: Often small pass-throughs for QC samples.

- Protocol: Similar to MAL but may use UV light and disinfection wiping as a transfer method for sealed containers.

Pressure Cascade Strategy

A differential pressure cascade is the primary engineering control to prevent airborne cross-contamination. Air flows from cleanest to less clean areas.

Table 2: Pressure Differential Design Standards

| Zone / Room | Typical Pressure Differential (Pascals, Pa) | Airflow Direction | Rationale |

|---|---|---|---|

| Grade A (ISO 5) Laminar Flow Hood | +45 to +55 Pa relative to Grade B | Outward from hood | Protects open product from immediate background. |

| Grade B (ISO 7) Core Rooms | +20 to +30 Pa relative to corridor | Outward from room | Maintains integrity of the aseptic processing suite. |

| Grade C (ISO 8) Corridor | +15 Pa relative to airlocks | Outward from corridor | Creates a buffer to unclassified areas. |

| Personnel Airlock (to corridor) | +10 to +15 Pa | From corridor into airlock | Prevents ingress of contamination during entry. |

| Personnel Airlock (to Grade B) | +5 to +10 Pa | From airlock into Grade B | Ensures outward flow at final entry point. |

| Contained Virus/Vector Suite | -20 to -30 Pa relative to adjacent areas | Inward to the suite | Contains biological hazards within the suite. |

| QC Microbiology Lab | -10 to -15 Pa relative to corridor | Inward to the lab | Contains testing microorganisms. |

Experimental Protocol: Pressure Cascade Verification

- Objective: To verify the designed pressure differentials between adjacent rooms are maintained under static and dynamic conditions.

- Equipment: Calibrated digital manometer, data logger, door open/close sensors.

- Method:

- Static Test: With all doors closed and HVAC in normal operation, record the pressure differential across each designated door for a minimum of 24 hours. Data logging intervals should be ≤5 minutes.

- Dynamic Test: Simulate worst-case personnel traffic. Have trained personnel move through a defined route, opening and closing doors per SOP. Record pressure differentials during these events, noting the maximum drop and recovery time to setpoint.

- Acceptance Criteria: All measured differentials must remain ≥ the minimum specified design value (e.g., +15 Pa) under static conditions. During dynamic testing, temporary drops below setpoint are permitted only if they recover to the minimum within a specified time (e.g., 3-5 seconds) and do not fall to or below 0 Pa.

Facility Pressure Cascade & Airflow Diagram

The Scientist's Toolkit: Critical Reagents & Materials for Process Validation

Table 3: Key Reagent Solutions for Cleanroom Performance Qualification

| Item | Function in Design Validation | Example/Note |

|---|---|---|

| Viable Particle Counter | Quantifies airborne microbial and particulate contamination per cubic meter in each ISO class zone. | Calibrated to sample at 1 CFM (28.3 LPM); used with agar strips for active air sampling. |

| Non-Viable Particle Counter | Measures and classifies cleanroom air by counting particles ≥0.5 μm and ≥5.0 μm. | Essential for formal ISO 14644-1 classification testing. |

| Anemometer / Balometer | Measures air velocity at HEPA filter faces and air volume changes per hour (ACH). | Verifies unidirectional laminar flow and room turnover rates. |

| Contact Plates (RODAC) | Surface monitoring for microbial contamination on floors, walls, and equipment. | Filled with tryptic soy agar (TSA) for bacterial growth. |

| Settle Plates | Passive air sampling to assess microbial fallout over a defined exposure time (e.g., 4 hours). | TSA plates for bacteria; Sabouraud dextrose agar (SDA) for fungi. |

| Vaporized Hydrogen Peroxide (VHP) Indicator | Biological or chemical indicators to validate decontamination cycles in MALs and isolators. | Geobacillus stearothermophilus spore strips are commonly used. |

| Digital Manometer | Validates the pressure differential cascade between all adjacent zones with logging capability. | Must have a resolution of at least 1 Pa and be calibrated traceably. |

| Neutralizing Broth | Used in disinfectant efficacy studies to stop the chemical action at the end of a specified contact time. | Validates that cleaning SOPs are effective. |

Selecting and Qualifying HVAC and Filtration Systems for ISO Class 5 (Grade A) Environments

Within the stringent framework of Good Manufacturing Practice (GMP) for cell therapy research, the cleanroom environment is a critical component for ensuring product sterility and patient safety. ISO Class 5 (equivalent to EU GMP Grade A) environments represent the highest air cleanliness standard for critical zones where high-risk operations, such as cell manipulation, fill-finish, and open-container processing, occur. This guide details the technical selection, design, and qualification of Heating, Ventilation, and Air Conditioning (HVAC) and filtration systems to achieve and maintain this classification, which is fundamental to preventing contamination in advanced therapy medicinal products (ATMPs).

Core System Requirements & Quantitative Specifications

Air Change Rates (ACRs) and Airflow

A unidirectional (laminar) airflow with a velocity of 0.45 m/s ±20% (90 ft/min ±20%) is mandated for ISO Class 5 zones to provide consistent particle sweeping action. For entire cleanrooms classified at ISO 5, very high air change rates (ACRs) are required.

| Parameter | ISO Class 5 / Grade A Specification | Typical Operational Range | Justification / Standard |

|---|---|---|---|

| Airflow Velocity | 0.36 - 0.54 m/s | 0.45 m/s (mean) | ISO 14644-3, EU GMP Annex 1 |

| Air Changes per Hour (ACR) | Not less than 600* | 600 - 800+ | *Derived from velocity & room volume; EU GMP Annex 1 states airflow should be "visible" |

| Airflow Pattern | Unidirectional (Laminar) | Vertical or Horizontal | Essential for particle control in critical zone |

| Room Pressurization | Positive pressure gradient relative to adjacent lower-grade areas | +10 to +15 Pa minimum | Prevents ingress of contamination (ISO 14644-4) |

Filtration Performance Specifications

Filtration is the final barrier for air quality. The system typically employs a multi-stage approach.

| Filtration Stage | Minimum Efficiency | Standard/Test Method | Typical Location & Function |

|---|---|---|---|

| Pre-filters (G4/F5) | 40-60% on 4µm particles | ISO 16890 | AHU intake; protects coils and subsequent filters from large particles. |

| Intermediate filters (F8/F9) | 80-95% on 0.4µm particles | ISO 16890/EN 779 | Downstream of conditioning coils; protects final HEPA from finer particles and moisture. |

| Final HEPA Filters (H13/H14) | ≥99.995% on 0.3µm particles (H14) | EN 1822 | At terminal point (ceiling or wall of cleanroom); ensures ISO Class 5 air. |

| ULPA Filters (U15) | ≥99.9995% on 0.12µm particles | EN 1822 | Used where enhanced viral containment is a concern. |

Detailed Qualification Methodologies (Experimental Protocols)

The qualification of the HVAC system follows a structured approach: Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ), aligning with GMP principles.

Protocol 1: HEPA Filter Integrity Testing (DOP/PAO Scan)

Objective: To verify the integrity of each installed HEPA filter and its seal, ensuring no bypass leakage. Materials: Aerosol generator (producing Di-Octyl Phthalate (DOP) or Poly-Alpha Olefin (PAO)), photometer, aerosol probe, scanning nozzle. Procedure:

- Establish upstream challenge aerosol concentration of 10-100 µg/L of air upstream of the filter.

- Use a calibrated photometer to measure downstream background.

- Scan the entire filter face, perimeter frame, and seal interface with the scanning nozzle held 1-2 cm from the surface.

- Move the nozzle in overlapping strokes at a linear rate not exceeding 5 cm/s.

- Any leakage reading exceeding 0.01% of the upstream challenge indicates a failure.

- Document all findings; failures require repair and re-test.

Protocol 2: Airflow Velocity and Uniformity Test

Objective: To confirm unidirectional airflow meets the specified velocity and uniformity across the entire critical zone. Materials: Calibrated anemometer (thermoelectric or ultrasonic), measuring grid. Procedure:

- Define a measurement plane parallel to the filter face, typically 15-30 cm below the filter for vertical flow.

- Divide the filter bank/ceiling area into a grid of equal sections (e.g., 1m x 1m or as per risk assessment).

- Measure the velocity at the center of each grid cell.

- Calculate the average velocity and the standard deviation. The average must be 0.45 m/s ±20%, and uniformity (relative standard deviation) should be within ±20% of the mean.

- Record all data points and generate a velocity map.

Protocol 3: Non-Viable Particle Count Qualification

Objective: To certify the room/zone meets ISO Class 5 particle count limits at "as-built," "at-rest," and "in-operation" states. Materials: Calibrated discrete particle counter with appropriate sample flow rate (e.g., 1 CFM or 50 L/min), isokinetic probe. Procedure:

- Determine sample locations based on room area (ISO 14644-1 formula: NL = √A, where A is area in m²).

- For each location, sample a minimum volume of air (as per ISO 14644-1, e.g., 1 m³ for ISO 5).

- Measure particles at sizes ≥0.5µm and ≥5µm.

- Compare the average concentration per location to the limit: ≤3,520 particles/m³ for ≥0.5µm and ≤29 particles/m³ for ≥5µm.

- The environment is compliant if all locations meet these limits.

Protocol 4: Recovery Test (Clean-up Rate)

Objective: To demonstrate the system's ability to recover from a simulated contamination event, confirming robust dynamic performance. Materials: Aerosol generator, particle counter. Procedure:

- Challenge the room with an aerosol to raise the ≥0.5µm particle count to 100x the ISO Class 5 limit.

- Stop aerosol generation and immediately start measuring particle counts at a defined critical location.

- Record the time taken for the particle count to reduce to 10% of the initial challenge (100:1 clean-up) or to the ISO Class 5 limit.

- The recovery time should be short (typically 2-4 minutes), demonstrating system efficacy.

System Design Logic and Qualification Workflow

Multi-Stage Filtration and Air Handling Process

The Scientist's & Engineer's Toolkit: Key Qualification and Monitoring Materials

| Item / Reagent Solution | Primary Function in Qualification/Monitoring | Technical Notes |

|---|---|---|

| PAO (Poly-Alpha Olefin) Aerosol | Challenge agent for HEPA filter integrity testing. | Non-toxic, chemically inert, replaces carcinogenic DOP. Used at 4-20 mg/m³ concentration. |

| Photometer (Forward Light Scatter) | Measures aerosol concentration upstream and downstream of HEPA during leak testing. | Must be calibrated with specific challenge aerosol. Provides real-time leak detection. |

| Discrete Particle Counter (DPC) | Counts and sizes non-viable particles for ISO classification. | Requires calibration to ISO 21501-4. Sample flow rates of 1 CFM (28.3 L/min) or 50 L/min are standard. |

| Thermo-Anemometer / Ultrasonic Anemometer | Measures air velocity and temperature for unidirectional airflow verification. | Must have appropriate range (0-1 m/s) and resolution (±0.01 m/s). Calibration traceable to national standards. |

| Microbial Air Sampler (Active) | Quantifies viable airborne particulate (CFU/m³) for microbiological monitoring. | Types: Sieve impactors (e.g., MAS-100), centrifugal samplers. Use appropriate culture media (e.g., TSA, SDA). |

| Contact Plates (RODAC) | Monitors surface microbial contamination on floors, walls, and equipment. | Filled with neutralizing culture media (e.g., TSA+LE). Incubated at appropriate temperatures (e.g., 20-25°C and 30-35°C). |

| Digital Manometer / Pressure Gauge | Measures room pressure differentials between adjacent zones. | High sensitivity (0.1 Pa resolution). Used for continuous monitoring and alarm systems. |

| Data Loggers (Temp/RH) | For mapping temperature and relative humidity uniformity across the cleanroom. | Should be calibrated and capable of synchronous data recording over a defined period (e.g., 7 days). |

The selection and rigorous qualification of HVAC and filtration systems are foundational to establishing and maintaining an ISO Class 5 environment compliant with GMP for cell therapy research. The process requires a systematic, science-based approach from design through to ongoing verification. By adhering to the specified quantitative parameters, executing detailed qualification protocols, and implementing continuous environmental monitoring with appropriate tools, facilities can ensure the aseptic conditions necessary to safeguard the sterility, efficacy, and safety of life-changing cell therapies.

Developing Robust SOPs for Gowning, Material Transfer, and Personnel Flow

1. Introduction and Thesis Context Within the framework of Good Manufacturing Practice (GMP) for cell therapy research, the cleanroom is the cornerstone of product safety and efficacy. The broader thesis posits that cleanroom classification (ISO 5/Class A to ISO 8/Class D) defines environmental limits, but it is the stringency of Standard Operating Procedures (SOPs) that controls the dynamic variables—people and materials—to maintain those limits. This guide details the technical development of robust SOPs for gowning, material transfer, and personnel flow, which are critical for minimizing particulate and microbiological contamination in aseptic cell processing.

2. Foundational Principles and Regulatory Basis SOPs must be built on the principles of contamination control, segregation, and unidirectional flow. Key regulatory and guidance documents include:

- EU GMP Annex 1: Manufacture of Sterile Medicinal Products (2022)

- USP <797> Pharmaceutical Compounding—Sterile Preparations

- FDA Guidance for Industry: Sterile Drug Products Produced by Aseptic Processing. A risk-based approach, aligned with ICH Q9, is mandatory, focusing on process critical control points.

3. Quantitative Data on Contamination Sources Effective SOPs target the primary sources of contamination. Data is summarized in Table 1.

Table 1: Primary Sources of Cleanroom Contamination

| Contamination Source | Particle Release Rate (≥0.5 μm/min) | Relative Risk in Cell Therapy | Primary Control SOP |

|---|---|---|---|

| Personnel (Gowned, in motion) | 100,000 - 1,000,000 | Very High | Gowning & Personnel Flow |

| Packaging Materials | Variable (1,000 - 10,000 per ft²) | High | Material Transfer & Decontamination |

| Stationary Personnel | ~100,000 | Moderate | Personnel Flow & Aseptic Technique |

| Equipment Transfer | Not Quantified (Situational) | High | Material Transfer & Sanitization |

4. SOP Development: Gowning Procedure The gowning SOP is a controlled sequence to encapsulate the operator as a contamination source.

4.1 Experimental Protocol for Gowning Qualification

- Objective: Quantify the effectiveness of the gowning SOP in reducing particle shedding.

- Methodology (Operator Gowning Qualification):

- The operator performs the gowning procedure in a designated gowning room (ISO 7 or better).

- Particle counters (remote and portable) are placed in the gowning room and adjacent cleaner area.

- Baseline particle counts are recorded.

- The operator performs standardized movements (arm raising, leg lifts, sitting/standing) for 10 minutes post-gowning.

- Particle counts (0.5 μm and 5.0 μm) are measured in real-time during the movement period.

- Microbial settle plates may be placed in the gowning area to assess bioburden reduction.

- The operator enters the main cleanroom, and particle counts are monitored to assess transfer.

- Acceptance Criteria: Particle counts must remain within the target cleanroom classification limits during and after the procedure.

4.2 Gowning Sequence Diagram

Diagram Title: Sequential Gowning Procedure for ISO 5/7 Cleanrooms

5. SOP Development: Material Transfer Material transfer SOPs define methods for introducing items without compromising cleanroom integrity.

5.1 Experimental Protocol for Transfer Validation

- Objective: Validate that a material transfer method (e.g., dynamic pass-through) maintains differential pressure and does not introduce contamination.

- Methodology:

- Place particle counters inside the cleanroom near the pass-through chamber (PTC) and in the PTC itself.

- Place microbial air samplers in the same locations.

- Execute the transfer SOP (e.g., wipe outer container, place in PTC, close outer door, sanitize interior, wait for purge cycle, retrieve from inner side).

- Monitor and log real-time particle counts (0.5 μm) and differential pressure across the PTC during the entire cycle.

- After transfer, sample surfaces of the transferred item and interior PTC surfaces for viable organisms using contact plates.

- Repeat for worst-case scenarios (largest, most irregular items).

- Acceptance Criteria: No loss of differential pressure > 1 Pa, particle counts return to baseline within minutes, and contact plates show no growth or within action limits.

5.2 Material Transfer Decision Workflow

Diagram Title: Material Transfer Method Decision Tree

6. SOP Development: Personnel Flow Personnel flow SOPs enforce unidirectional movement and minimize cross-contamination between zones of different classifications.

6.1 Core Principles & Logical Flow The primary rule is movement from lower to higher classification only after proper gowning. Reverse flow requires re-gowning. A clear mapping of zones and airlocks is essential.

6.2 Personnel Flow Pathway Diagram

Diagram Title: Unidirectional Personnel Flow for Cell Therapy Suite

7. The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Materials for Contamination Control & SOP Validation

| Item Category | Specific Example/Product | Function in SOP Development/Execution |

|---|---|---|

| Environmental Monitoring | Portable Laser Particle Counter, Microbial Air Sampler, Contact Plates (TSA, SDA) | Provides quantitative data for SOP validation, routine monitoring, and media fills. |

| Surface Decontamination | Sporicidal Wipes (e.g., hydrogen peroxide, peracetic acid based), Sterile 70% IPA Wipes | Validated agents for decontaminating materials, surfaces, and gloves during transfers and operations. |

| Gowning Materials | Sterile, Low-Linting Gowns; Sterile Nitrile Gloves; Face Masks with Full Coverage | Barrier materials that meet ASTM standards for particulate and microbial shedding. |

| Material Transfer | Validated Double-Bag Assemblies, Pass-Through Chambers with Interlocks, Rapid Transfer Ports (RTPs) | Engineered systems that enable the controlled, aseptic introduction of materials. |

| Hand Hygiene | Validated Surgical Hand Scrub, Alcohol-Based Hand Sanitizer (with persistent effect) | Critical for reducing resident and transient flora before gowning and gloving. |

8. Conclusion Robust SOPs for gowning, material transfer, and personnel flow are not administrative documents but are dynamic, validated protocols that physically enforce the principles of GMP. For cell therapy research, where the product is often both the drug and the patient's own cells, these SOPs constitute the primary defense against adventitious agent contamination, directly impacting patient safety and product viability. Their development must be evidence-based, continuously monitored, and ingrained in the quality culture of the organization.

Within the context of Good Manufacturing Practice (GMP) for cell therapy research, the maintenance of designated cleanroom classifications (ISO 5/Class A to ISO 8/Class D) is non-negotiable. The product—often autologous or allogeneic living cells—is uniquely susceptible to both viable and non-viable particulate contamination, which can compromise patient safety and therapeutic efficacy. Routine and periodic environmental monitoring (EM) forms the cornerstone of contamination control strategy, providing the data to demonstrate state of control, identify trends, and trigger corrective actions. This whitepaper provides an in-depth technical guide to the three principal tools for airborne monitoring: particle counters, microbial air samplers, and settle plates.

Particle Counters: Quantifying Non-Viable Contamination

Optical particle counters (OPCs) operate on light scattering principles. A vacuum pump draws air at a controlled rate (e.g., 1.0 cubic foot per minute, 28.3 liters per minute, or 50 liters per minute) through a laser-illuminated sensing zone. Particles scatter light, with the intensity proportional to particle size, which is then counted and sorted into size channels (typically ≥0.5 µm and ≥5.0 µm for ISO classifications).

Key Experimental Protocol for Routine Monitoring

- Apparatus: Calibrated isokinetic probe, portable or remote particle counter with ≥0.5 µm and ≥5.0 µm channels, data logging software.

- Procedure:

- Perform pre-operation checks (flow rate verification, zero count check).

- For static (at-rest) classification, sample for 1 minute per location. For dynamic (in-operation) monitoring, sample continuously or at frequent intervals.

- Position the isokinetic probe in the airflow (vertical for unidirectional, strategic for non-unidirectional).

- Sample at pre-defined, risk-assessed locations: workbench height, near critical sites (e.g., vial fill, open processing), and room background.

- Record counts per cubic meter for each channel. Calculate mean from multiple locations for classification compliance.

Data Presentation: ISO 14644-1 Classification Limits (Particles/m³)

| ISO Class | ≥0.5 µm | ≥5.0 µm |

|---|---|---|

| ISO 5 (Class 100) | 3,520 | 29 |

| ISO 6 (Class 1,000) | 35,200 | 293 |

| ISO 7 (Class 10,000) | 352,000 | 2,930 |

| ISO 8 (Class 100,000) | 3,520,000 | 29,300 |

Microbial Air Samplers: Capturing Viable Contaminants

Active Air Sampling Methods

Active samplers draw a known volume of air onto or into a collection medium.

- Impaction (Slit-to-Agar, Sieve): Air is accelerated through small jets (sieve) or a slit and directed onto a 55-60mm agar plate (e.g., TSA, SDA). Microbes are physically impacted onto the surface.

- Centrifugal: A rotating impeller draws air inward and deposits particles onto a dedicated agar strip via centrifugal force.

- Filtration: Air passes through a membrane filter, which is then placed on agar or immersed in broth for incubation.

- Impinger: Air is bubbled through a liquid collection medium.

Key Experimental Protocol for Viable Air Sampling

- Apparatus: Calibrated microbial air sampler (sieve impactor recommended), pre-poured agar plates (TSA for bacteria, SDA for fungi), incubators.

- Procedure:

- Decontaminate sampler intake.

- Aseptically load sterile agar plate into sampler.

- Program sample volume (typically 1 m³ for ISO 5/6, lower volumes for dirtier areas to avoid overloading).

- Sample at critical locations. Ensure sampling head is oriented correctly per manufacturer (often facing upwards).

- Incubate plates: TSA at 30-35°C for 48-72 hours; SDA at 20-25°C for 5-7 days.

- Count Colony Forming Units (CFU) and calculate CFU/m³.

Data Presentation: Example Alert/Action Limits for Viable Air (CFU/m³)

| Cleanroom Grade (Dynamic) | Recommended Action Limit (CFU/m³) |

|---|---|

| ISO 5 (Class A) | <1 |

| ISO 6 (Class B) | 10 |

| ISO 7 (Class C) | 100 |

| ISO 8 (Class D) | 200 |

Settle Plates: Passive Air Monitoring

Principle and Rationale

Settle plates (typically 90mm agar plates) measure the deposition rate of viable, airborne particles under gravity over a defined exposure time (usually 4 hours for critical operations). This method is particularly relevant for assessing contamination risk to open product containers.

Key Experimental Protocol

- Apparatus: Pre-poured agar plates, sterile tripods/stands, timing device.

- Procedure:

- Remove lid from plate and place on a stand at a defined working height (e.g., bench level, near open processing).

- Expose for a validated duration (e.g., ≤4 hours to avoid desiccation).

- Replace lid, incubate as per active air samples.

- Count CFU per plate, report as CFU/4 hours.

Integration into a GMP Contamination Control Strategy

Effective EM programs integrate all three methods at frequencies defined by risk assessment. Data from particle counters provide real-time feedback on HVAC performance, while viable methods offer retrospective but critical biological data. Trend analysis is essential.

Cleanroom EM Data Flow for GMP Compliance

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Cleanroom Monitoring |

|---|---|

| Tryptic Soy Agar (TSA) Plates | General-purpose medium for the recovery of aerobic bacteria and fungi. Used in active air samplers and settle plates. |

| Sabouraud Dextrose Agar (SDA) Plates | Selective medium optimized for fungi and yeasts. Used for monitoring in areas prone to mold contamination. |

| Neutralizing Agar (e.g., with Lecithin & Polysorbate) | Contains agents to inactivate residual disinfectants (e.g., sporicides) that could inhibit microbial growth, ensuring accurate counts. |

| Particle Counter Calibration Kit | Contains size-calibrated polystyrene latex spheres (e.g., 0.5µm, 5.0µm) and a flow meter to verify instrument accuracy per ISO 21501-4. |

| Microbial Air Sampler Calibration Equipment | A primary standard (e.g., bubble meter, mass flow meter) to certify the sampler's air intake volume is accurate. |

| Incubators (Dual-Temperature) | Required for incubation of plates at both 20-25°C (for fungi) and 30-35°C (for bacteria) to capture the full spectrum of viable contaminants. |

Integrating Cleanroom Data with QMS (Quality Management System) for Real-Time Compliance

Within the stringent framework of GMP (Good Manufacturing Practice) for cell therapy research, the cleanroom is the nexus of product quality. Its classification—defined by parameters like airborne particle counts, pressure differentials, temperature, and humidity—directly impacts the safety and efficacy of living cellular products. Traditional compliance models rely on periodic data review, a reactive approach fraught with latency. This guide details the technical integration of continuous cleanroom environmental monitoring (EM) data directly into a modern electronic Quality Management System (eQMS) to achieve real-time compliance, enabling proactive deviation management and ensuring data integrity within the critical manufacturing environment.

Core Data Architecture & Integration Protocol

The integration requires a robust, layered architecture to facilitate seamless, bi-directional data flow between cleanroom sensors and the eQMS.

Integration Methodology

Protocol: Establishment of a Unified Data Pipeline

- Sensor Layer: Deploy validated, networked particle counters (e.g., 0.5 µm and 5.0 µm sizing), microbial air samplers, and physicochemical sensors (pressure, temp, RH). Each device must be calibrated per a traceable schedule.

- Data Acquisition & Aggregation: Utilize an Environmental Monitoring Software (EMS) or a custom middleware (e.g., built on MQTT/Sparkplug or OPC UA protocols) to collect raw data streams from all sensors. This layer performs initial data cleansing and time-synchronization.

- Translation & Normalization Layer: Implement a secure API gateway (RESTful or SOAP) to map EMS data fields to the specific input requirements of the target eQMS. This includes normalizing units, aligning sensor IDs with equipment master records, and applying data formats (ISO 8601 for timestamps).

- eQMS Ingestion: Configure the eQMS (e.g., Veeva Vault QMS, SAP QM, or MasterControl) to accept incoming data via API as Potential Deviations or Quality Events. Business rules within the eQMS are pre-configured to trigger automated workflows based on alert (e.g., > ISO Class 5 limit) or action level breaches.

Logical Workflow Diagram

Title: Cleanroom-to-QMS Real-Time Data Workflow

Key Cleanroom Parameters & Alert Thresholds

For cell therapy GMP manufacturing, cleanrooms are typically classified as ISO Class 5 (Grade A) for critical aseptic processing and ISO Class 7 (Grade B) as background. The following table summarizes key quantitative limits and their QMS impact.

Table 1: Critical Cleanroom Parameters & Integration Triggers for Cell Therapy

| Parameter | ISO Class 5 (Grade A) Limit (at rest) | ISO Class 7 (Grade B) Limit (at rest) | Typical Sampling Frequency | QMS Event Trigger Level |

|---|---|---|---|---|

| Airborne Particles (≥0.5 µm) | 3,520 per m³ | 352,000 per m³ | Continuous | Alert: 80% of limit; Action: 100% of limit |

| Airborne Particles (≥5.0 µm) | 20 per m³ | 2,930 per m³ | Continuous | Alert: 80% of limit; Action: 100% of limit |

| Microbial Viable Air (CFU/m³) | <1 | 10 | Daily/Session | Action: Any growth in Grade A; >Limit in Grade B |

| Pressure Differential | ≥10-15 Pa | ≥10-15 Pa | Continuous | Alert: Deviation > ±2 Pa from setpoint |

| Temperature | Controlled per SOP (e.g., 20±2°C) | Controlled per SOP | Continuous | Alert: Deviation > ±1°C from setpoint |

| Relative Humidity | Controlled per SOP (e.g., 45±10%) | Controlled per SOP | Continuous | Alert: Deviation > ±5% from setpoint |

Experimental Protocol for System Validation

Any integration must be validated to ensure data integrity, accuracy, and reliability. The following protocol outlines the core validation exercise.

Protocol: Validation of the Cleanroom Data-to-QMS Integration Loop

- Objective: To demonstrate that a simulated cleanroom excursion detected by the EMS is accurately, completely, and timely transmitted to the eQMS, triggering the correct quality workflow.

- Materials: See "The Scientist's Toolkit" below.

- Method:

- Baseline Configuration: Confirm all sensors are calibrated and the API connection between the EMS and eQMS is active. In the eQMS, configure a test Quality Event workflow that culminates in a specific test-CAPA form.

- Excursion Simulation: Using a calibrated particle counter calibrator or a non-shedding source, introduce a controlled concentration of particles (≥0.5 µm) into the sampling line of a single ISO Class 5 particle counter to simulate a breach of the "Action Level."

- Data Trace Monitoring: In the EMS interface, verify the excursion is recorded. Simultaneously, monitor the API traffic using a network protocol analyzer (e.g., Wireshark) to confirm data transmission.

- eQMS Event Verification: Log into the eQMS and check for the automatic creation of a new Quality Event record. Verify that all metadata (sensor ID, timestamp, location, exact particle count) is correctly populated.

- Workflow Trigger Confirmation: Manually progress the test Event to confirm the subsequent workflow steps (e.g., notification to QA, initiation of investigation form) are triggered as designed.

- Data Integrity Check: Perform an audit trail review in both the EMS and eQMS for the test record. Ensure the trace is unbroken, timestamped, and attributable.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Cleanroom Monitoring & Integration Validation

| Item | Function in Context |

|---|---|

| Calibrated Particle Counter (e.g., with 0.5µm & 5.0µm channels) | Primary device for continuous monitoring of airborne particulate contamination against ISO classification standards. |

| Aerosol Generator & Diluter | Used in validation protocols to generate known concentrations of polystyrene latex spheres (PSL) for sensor challenge testing and excursion simulation. |

| Microbial Air Sampler (e.g., viable impactor) | Active air monitoring to quantify viable (CFU) contamination, critical for aseptic processing assurance. |

| Environmental Monitoring Software (EMS) | Centralized platform for real-time data collection, visualization, and alarm management from all cleanroom sensors. |

| API Testing & Simulation Tool (e.g., Postman, SoapUI) | Validates the data structure, security, and reliability of the connection between the EMS and the eQMS. |

| Network Protocol Analyzer (e.g., Wireshark) | Captures and analyzes API traffic to verify data completeness and timing during integration validation. |

| Electronic QMS Sandbox/Test Instance | A non-production replica of the QMS used to develop, test, and validate integration workflows without impacting live quality records. |

Signaling Pathway for Real-Time Deviation Management

The integrated system creates an automated, logical pathway for managing deviations, transforming raw data into quality actions.

Title: Real-Time Deviation Management Pathway

Solving Common Cleanroom Challenges: Contamination Control and Deviation Management

Root Cause Analysis for Excursions in Particle and Microbial Monitoring Data

Within the context of Good Manufacturing Practice (GMP) cleanroom classification for cell therapy research, environmental monitoring (EM) is a critical quality attribute. Cell therapy products, particularly those involving autologous or allogeneic live cells, are highly susceptible to contamination. Excursions—data points exceeding established alert or action limits for airborne particulates or viable microorganisms—represent potential threats to product sterility, patient safety, and data integrity. A systematic Root Cause Analysis (RCA) is therefore not merely a regulatory expectation but a fundamental component of a robust quality culture. This guide details a structured RCA methodology tailored for the cell therapy research environment.

A Structured RCA Framework

A systematic, cross-functional approach is essential. The following framework provides a logical progression from identification to closure.

Diagram Title: RCA Process Workflow for EM Excursions

Quantitative Data Analysis and Trend Review

Isolated excursions must be viewed against historical data and room dynamics. Key metrics should be compiled for analysis.

Table 1: Critical EM Data for RCA Baseline

| Data Category | Specific Parameter | Typical Acceptable Range (ISO 5 / Grade A) | Relevance to RCA |

|---|---|---|---|

| Particle (≥0.5µm) | Average Count (per m³) | ≤3,520 | Baseline performance of HEPA filtration. |

| Peak Count (per m³) | Dynamic, but must not compromise classification. | Correlates with specific personnel or equipment activity. | |

| Viable Air | Colony Forming Units (CFU) per m³ | <1 | Direct sterility risk indicator. |

| Viable Surface | CFU per contact plate (e.g., 55cm²) | <1 | Integrity of disinfection protocols and aseptic technique. |

| Personnel | CFU per glove print (per hand) | <1 | Primary source of microbial contamination. |

| Facility | Pressure Differential (Pa) | ≥10-15 Pa (cascading) | Identifies airflow reversal risks. |

| Air Change per Hour (ACH) | ≥300-600 (unidirectional) | Assesses contamination dilution rate. |

Common Root Causes & Investigative Protocols

Personnel-Related Causes

- Root Cause: Improper aseptic gowning, technique, or high personnel density.

- Investigation Protocol:

- Review gowning qualification records of involved personnel.

- Simulate the operation using smoke studies or particle counters placed near personnel to visualize airflow disruption.

- Re-enact the activity with intensified EM (e.g., settle plates, active air samplers at the point of operation) to confirm the correlation.

Equipment & Process-Induced Turbulence

- Root Cause: Introduction of non-sanitized materials, equipment-generated particles, or improper setup disrupting unidirectional airflow.

- Investigation Protocol:

- Perform non-viable particle monitoring during equipment operation outside and inside the critical zone.

- Conduct surface sampling on equipment pre- and post-introduction into the cleanroom.

- Execute a media simulation (media fill) that incorporates the specific equipment operation to challenge microbial risk.

Facility & Engineering Controls Failure

- Root Cause: HVAC system malfunction, HEPA filter leak, loss of room pressure differential.

- Investigation Protocol:

- Immediately review Building Management System (BMS) logs for pressure, temperature, and humidity deviations.

- Perform a full integrity test (DOP/PAO challenge) on the HEPA filters serving the affected zone.

- Measure air change rates and airflow visualization studies (smoke tests) to confirm unidirectional airflow patterns.

Procedural & Training Deficiencies

- Root Cause: Inadequate or outdated SOPs, insufficient training on contamination control.

- Investigation Protocol: