GMP Standards for Clinical-Grade MSC-EV Production: A Comprehensive Guide for Researchers and Biotech Professionals

This article provides a comprehensive, up-to-date guide to Good Manufacturing Practice (GMP) standards for producing Mesenchymal Stromal Cell-derived Extracellular Vesicles (MSC-EVs) for clinical applications.

GMP Standards for Clinical-Grade MSC-EV Production: A Comprehensive Guide for Researchers and Biotech Professionals

Abstract

This article provides a comprehensive, up-to-date guide to Good Manufacturing Practice (GMP) standards for producing Mesenchymal Stromal Cell-derived Extracellular Vesicles (MSC-EVs) for clinical applications. Targeting researchers, scientists, and drug development professionals, it systematically covers the fundamental rationale for GMP compliance, detailed methodologies for scalable and reproducible manufacturing, critical troubleshooting strategies for common production challenges, and rigorous approaches for product validation and comparability assessment. By integrating the latest regulatory perspectives with practical implementation strategies, this guide aims to bridge the gap between bench-scale MSC-EV research and the development of standardized, clinically viable therapeutic products.

Why GMP is Non-Negotiable: The Foundational Principles of Clinical-Grade MSC-EV Manufacturing

The transition from Research-Grade to Clinical-Grade Mesenchymal Stromal Cell-Extracellular Vesicles (MSC-EVs) is pivotal for therapeutic applications. The core distinction lies in the implementation of Good Manufacturing Practice (GMP) standards, which ensure safety, purity, potency, and identity of the final product. Research-grade EVs facilitate biological discovery, while clinical-grade EVs are manufactured as active pharmaceutical ingredients (APIs) for human administration.

Comparative Analysis: Research vs. Clinical-Grade Production

The table below summarizes the critical differences across key production parameters.

Table 1: Key Distinctions Between Research and Clinical-Grade MSC-EV Production

| Parameter | Research-Grade MSC-EVs | Clinical-Grade MSC-EVs |

|---|---|---|

| Primary Objective | Mechanistic understanding, proof-of-concept | Safety and efficacy in humans (Therapeutic product) |

| Cell Source | Research cell lines, often poorly characterized | Fully traceable, qualified Master Cell Bank (MCB) under GMP |

| Culture System | Fetal Bovine Serum (FBS), 2D flasks | Xeno-free, serum-free media; often 3D bioreactors |

| Process Control | Variable, lot-to-lot inconsistency | Fully defined, validated, and consistent SOPs |

| Purification | Research kits (e.g., precipitation), ultracentrifugation | Scalable, closed-system methods (e.g., TFF, SEC, AEX) |

| Characterization | Minimal (protein, particle count), research-focused | Extensive and mandated: Identity (CD63/81/CD9, neg for GM130), Potency, Purity (host cell protein/DNA), Safety (sterility, endotoxin) |

| Quality System | Laboratory notebook | Pharmaceutical Quality System (PQS) with full traceability (batch records) |

| Documentation | Experimental protocols | Chemistry, Manufacturing, and Controls (CMC) dossier for regulatory submission |

| Storage & Stability | -80°C, short-term stability studies | Defined formulation, validated long-term stability under GMP conditions |

Essential Protocols for Clinical-Grade MSC-EV Development

Protocol 3.1: Establishment of a GMP-Compliant MSC Master Cell Bank

Objective: To create a characterized, cryopreserved MCB from a qualified donor tissue source for all future EV production.

- Source Material: Obtain human tissue (e.g., bone marrow, umbilical cord) with full donor consent, screening, and traceability.

- Isolation & Expansion: Isolate MSCs using a xeno-free, enzymatic digestion or explant method. Perform initial expansion in GMP-grade, serum-free, chemically defined medium.

- Banking: At population doubling level (PDL) 3-4, harvest cells, formulate in a GMP-grade cryoprotectant (e.g., Human Serum Albumin + DMSO), and fill into validated cryovials. Create 50-100 vials as the MCB. Cryopreserve in a validated rate-controlled freezer, then transfer to liquid nitrogen vapor phase.

- Characterization: Test MCB vials for:

- Identity: ≥95% positive for CD73, CD90, CD105; ≤5% positive for CD34, CD45, CD11b, CD19, HLA-DR (Flow Cytometry, ISCT criteria).

- Viability: ≥90% post-thaw viability.

- Sterility: Negative for bacterial/fungal growth (BacT/ALERT).

- Mycoplasma: Negative (e.g., PCR-based assay).

- Adventitious Viruses: Test per ICH Q5A(R1) guidelines.

- Karyotype: Normal diploid karyotype.

Protocol 3.2: Scalable EV Production in a Bioreactor System

Objective: To produce large quantities of MSC-EVs under controlled, monitored, and reproducible conditions.

- Thaw and Expansion: Thaw one MCB vial and expand cells in stacked culture vessels or a seed train to generate sufficient biomass.

- Bioreactor Inoculation and Culture: Inoculate cells into a controlled bioreactor (e.g., hollow-fiber or stirred-tank) with GMP-grade, serum-free, EV-depleted medium. Set parameters: pH 7.2-7.4, DO 30-60%, temperature 37°C. Monitor glucose/lactate.

- Conditioned Media Harvest: Initiate a perfusion or fed-batch process. Once cells reach >80% confluency, replace medium with a production medium (may be reduced volume/serum-free). Harvest conditioned media (CM) continuously or at set intervals (e.g., every 48-72h) while maintaining cell viability >85%.

- Clarification: Pool harvested CM and perform immediate low-speed centrifugation (e.g., 2000 x g, 30 min, 4°C) followed by 0.22 µm filtration to remove cells and large debris.

Protocol 3.3: Tangential Flow Filtration (TFF) for EV Purification

Objective: To concentrate and purify EVs from clarified CM using a scalable, closed-system method.

- System Setup: Assemble a sterile, single-use TFF cassette (e.g., 300-500 kDa MWCO) and tubing set. Flush system with GMP-grade Water for Injection (WFI), followed by equilibration buffer (e.g., sterile PBS).

- Concentration & Diafiltration: Load clarified CM into the feed reservoir. Concentrate the retentate to ~1/50th of the starting volume. Initiate diafiltration with 5-10 volumes of PBS or the final formulation buffer to exchange the medium and remove soluble contaminants.

- Final Recovery: Recover the concentrated retentate containing EVs. Flush the system with formulation buffer to maximize yield.

- Sterile Filtration: Pass the final retentate through a 0.22 µm PES syringe filter into a sterile product container.

Protocol 3.4: Potency Assay: EV-Mediated Macrophage Polarization

Objective: To quantify the biological activity (potency) of MSC-EVs by their capacity to induce anti-inflammatory macrophages.

- THP-1 Cell Differentiation: Culture THP-1 monocytes with 100 ng/mL PMA for 48h to differentiate into M0 macrophages. Wash and rest for 24h in RPMI with 10% exosome-depleted FBS.

- EV Treatment & Polarization: Seed M0 macrophages. Treat cells with a standardized dose of MSC-EVs (e.g., 1e9 particles/mL) or reference standard. Co-stimulate with 20 ng/mL IFN-γ and 100 ng/mL LPS to induce pro-inflammatory (M1) polarization. Incubate for 48h.

- Flow Cytometry Analysis: Harvest cells. Stain for surface markers: CD206 (M2 marker) and CD86 (M1 marker). Include isotype controls.

- Data Interpretation: Calculate the ratio of %CD206+ to %CD86+ cells. A higher ratio indicates greater anti-inflammatory potency. The assay must meet pre-defined acceptance criteria for a batch to be released (e.g., ratio > 2.0 relative to a negative control).

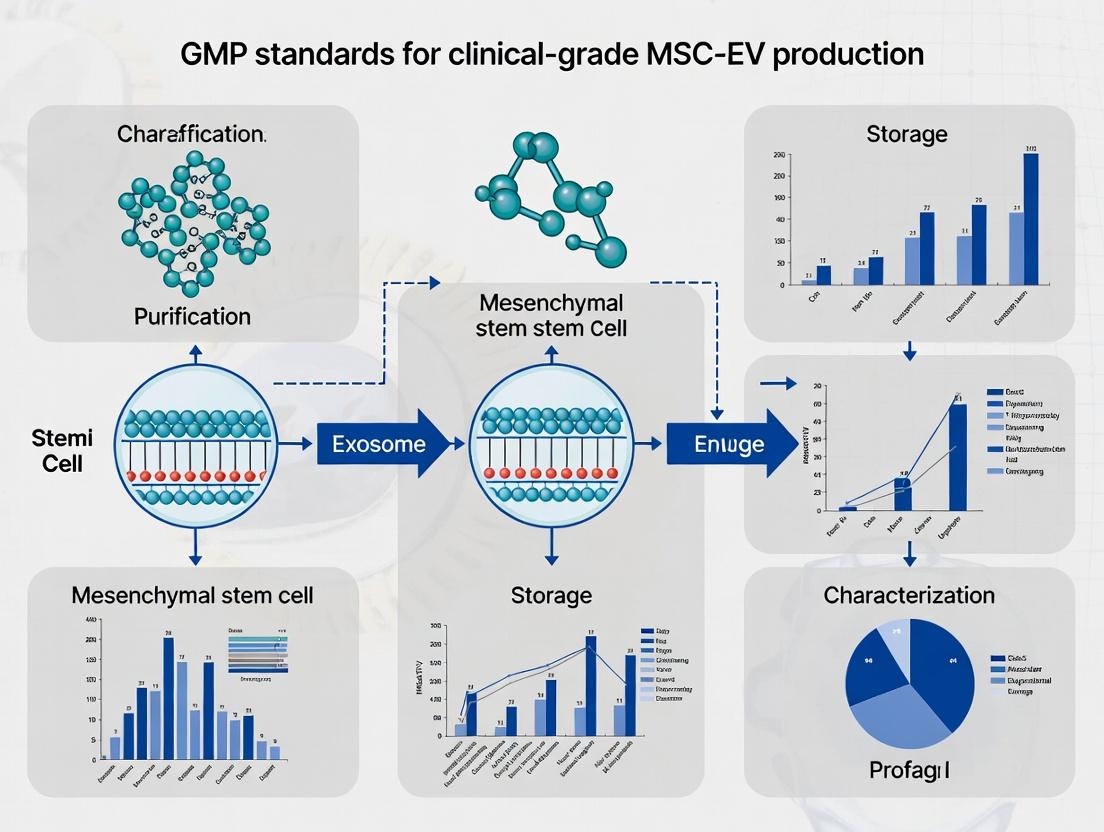

Visualizing Key Concepts and Workflows

Title: Roadmap from Research to Clinical MSC-EV Product

Title: Mechanism of MSC-EV Potency Assay

The Scientist's Toolkit: Key Reagents & Materials for Clinical-Grade EV Work

Table 2: Essential Toolkit for Clinical-Grade MSC-EV Development

| Category | Item | Function & Rationale |

|---|---|---|

| Cell Source | GMP-Grade Human Tissue (e.g., Bone Marrow) | Starting material with full traceability and donor screening. |

| Cell Culture | Xeno-Free, Serum-Free MSC Medium (e.g., STEMxyme MSC, PRIME-XV) | Eliminates animal-derived components, ensures consistency, and prevents bovine EV contamination. |

| Banking | GMP-Grade DMSO & Human Serum Albumin | Cryoprotectant components for creating Master Cell Banks under GMP. |

| Production | Single-Use Bioreactor (e.g., hollow-fiber, stirred tank) | Enables scalable, controlled, and closed-system expansion of MSCs for EV production. |

| Harvest | 0.22 µm PES Sterile Filters | Clarification of conditioned media to remove cells and large debris. |

| Purification | Tangential Flow Filtration (TFF) Cassette (300-500 kDa) | Scalable concentration and buffer exchange; key GMP-compatible purification step. |

| Characterization | Tunable Resistive Pulse Sensing (TRPS) System (e.g., qNano) | Measures particle concentration and size distribution with high resolution. |

| Characterization | CD63/CD81/CD9 ELISA Kit (GMP-compliant) | Quantifies EV-associated tetraspanins for identity testing. |

| Characterization | Recombinant Protein Standards (e.g., for Flow Cytometry) | Critical for quantitative assay calibration and validation. |

| Safety Testing | Limulus Amebocyte Lysate (LAL) Assay Kit | Quantifies endotoxin levels to ensure product safety (<0.5 EU/mL for injectables). |

The regulatory landscape for clinical-grade Mesenchymal Stromal Cell-derived Extracellular Vesicle (MSC-EV) production is defined by foundational guidelines from the U.S. Food and Drug Administration (FDA), the European Medicines Agency (EMA), and the International Council for Harmonisation (ICH). These frameworks, applied within a GMP (Good Manufacturing Practice) context, ensure product quality, safety, and efficacy from donor to final product.

Table 1: Key Regulatory Guideline Comparison for MSC-EV Production

| Aspect | FDA (CBER) | EMA (ATMP Regulation) | ICH Quality Guidelines |

|---|---|---|---|

| Legal Basis | PHS Act 351; 21 CFR Parts 210, 211, 1271 | Regulation (EC) 1394/2007; Directive 2001/83/EC | Harmonised technical requirements adopted by regions. |

| Classification | Somatic Cell Therapy Product / Biologic (BLA pathway) | Advanced Therapy Medicinal Product (ATMP) | Not a legal authority; provides harmonised standards. |

| GMP Foundation | 21 CFR 210 & 211; Guidance for Human Cells, Tissues, and Cellular and Tissue-Based Products (HCT/Ps) | EudraLex Volume 4, Part IV (ATMP GMP) | ICH Q7: GMP for Active Pharmaceutical Ingredients. |

| Quality System | Quality by Design (QbD) principles encouraged. | Comprehensive Quality System mandated. | ICH Q9: Quality Risk Management. ICH Q10: Pharmaceutical Quality System. |

| Critical Focus for MSC-EVs | Identity, purity, potency, safety (adventitious agents), manufacturing consistency. | Risk-based approach, characterization, stability, traceability. | Application of Q9 risk assessment and Q10 management review across product lifecycle. |

| Stability Requirement | Real-time data for shelf-life determination. | Real-time stability studies under recommended storage conditions. | Covered under ICH Q1 and Q5C, referenced by Q10. |

| Key Recent Guidance | CMC Information for Human Gene Therapy INDs (2020); Potency Assurance (2021). | Guideline on quality, non-clinical & clinical aspects of ATMPs (2023). | Ongoing revisions; Q9(R1) revised in 2023 emphasizing formality in risk management. |

Table 2: Quantitative Quality Attribute Targets for MSC-EVs (Illustrative)

| Quality Attribute | Analytical Method | Proposed Target Specification | Associated ICH/FDA/EMA Concept |

|---|---|---|---|

| Particle Concentration | Nanoparticle Tracking Analysis (NTA) | ≥ 1.0 x 10^10 particles/mL; CV < 20% batch-to-batch | ICH Q6B: Test Procedures and Acceptance Criteria |

| Particle Size (Mode) | NTA / Tunable Resistive Pulse Sensing | 80 - 200 nm | ICH Q6B: Characterization |

| EV-Specific Markers | Flow Cytometry (CD9, CD63, CD81) | Positive for ≥ 2 transmembrane markers | FDA Potency: Link to mechanism |

| MSC-Specific Markers | Flow Cytometry (CD73, CD90, CD105) | Positive (>90% population) | Identity (ICH Q6B) |

| Negative Markers | Flow Cytometry (CD14, CD45, HLA-DR) | Negative (<5% population) | Purity (ICH Q6B) |

| Protein Contaminant | BCA / ELISA (e.g., Apolipoprotein B) | ≤ 5% of total protein | Purity; Risk of co-isolation (ICH Q9) |

| Bioburden | Sterility test (EP 2.6.1 / USP <71>) | Sterile | EMA GMP Annex 1; ICH Q6A |

| Endotoxin | LAL test | < 0.5 EU/mL | FDA Pyrogen Test; EP 2.6.14 |

Experimental Protocols

Protocol 1: Risk Assessment for MSC-EV Manufacturing Process (Based on ICH Q9(R1))

Objective: To systematically identify, analyze, and evaluate critical risks in the MSC-EV manufacturing workflow from cell banking to final fill.

Materials:

- Risk Assessment Team (Multi-disciplinary: Process Development, QC, QA, Regulatory).

- Process Flow Diagram (See Diagram 1).

- Risk Assessment Tool (e.g., Failure Mode and Effects Analysis - FMEA template).

- ICH Q9(R1) Guideline.

Procedure:

- Define Risk Question: "What are the risks to the Critical Quality Attributes (CQAs: identity, purity, potency, safety) of the final MSC-EV product?"

- Assemble Team & Define Scope: Include members with expertise in MSC biology, EV isolation, analytics, and GMP. Scope: All steps from Thawing of MSC Working Cell Bank to Final Filled EV Product.

- Hazard Identification: Using the process map, brainstorm potential failure modes for each unit operation (e.g., "During cell expansion: low cell viability").

- Risk Analysis (Severity x Occurrence):

- Severity (S): Score 1 (negligible) to 5 (catastrophic) impact on CQAs/patient safety.

- Occurrence (O): Score 1 (rare) to 5 (very likely) based on historical or development data.

- Calculate Preliminary Risk Priority Number (RPN) = S x O.

- Risk Evaluation: Prioritize risks. Example: "Introduction of mycoplasma during cell culture" (S=5, O=2, RPN=10) is high severity and requires control.

- Risk Control: For unacceptable risks, define control measures. Example: Mitigation for mycoplasma: use of End-of-Production Cell banking with full compendial testing (ICH Q5A, EP 2.6.7).

- Risk Review: Document assessment. Re-evaluate risks post-mitigation and at defined milestones (per ICH Q10, Management Review).

Protocol 2: Critical Quality Attribute (CQA) Assessment for Potency (Linking FDA/EMA/ICH)

Objective: To establish a quantitative, mechanism-based potency assay for MSC-EVs intended for an immunomodulatory indication.

Materials:

- Test Article: Purified MSC-EV batch.

- Cells: Human peripheral blood mononuclear cells (PBMCs), activated with e.g., anti-CD3/CD28 beads.

- Assay Reagents: IL-2, IFN-γ ELISA kits; cell culture media.

- Equipment: CO2 incubator, ELISA plate reader.

Procedure:

- Principle: MSC-EVs should suppress T-cell activation/proliferation, a key mechanism of action (MOA). Assay measures inhibition of IFN-γ release.

- PBMC Activation:

- Isolate PBMCs from healthy donor leukopak.

- Seed 2 x 10^5 cells/well in a 96-well plate.

- Add T-cell activation beads at a pre-optimized cell:bead ratio.

- EV Treatment:

- Prepare a dilution series of MSC-EVs (e.g., 1e7 to 1e9 particles/well) in culture medium.

- Add EV dilutions to activated PBMCs. Include controls: activated PBMCs only (max IFN-γ), non-activated PBMCs (background), and a reference MSC-EV standard if available.

- Incubate for 72 hours at 37°C, 5% CO2.

- Analysis:

- Centrifuge plate, collect supernatant.

- Perform IFN-γ ELISA per manufacturer's protocol.

- Calculate % inhibition relative to activated control for each EV concentration.

- Data Interpretation & Specification:

- Plot dose-response curve. Determine IC50 (concentration causing 50% inhibition).

- Establish Provisional Potency Specification: e.g., "The test article shall inhibit IFN-γ production by ≥ 40% at a concentration of 1e8 particles/well relative to the activated control." This links the product attribute (EV concentration) directly to a biological function, addressing FDA/EMA potency expectations and ICH Q6B.

Visualizations

Diagram 1 Title: MSC-EV GMP Production and Control Workflow

Diagram 2 Title: ICH Q10 Pharmaceutical Quality System for MSC-EVs

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Reagents for MSC-EV Process Development & QC

| Reagent / Material | Function in MSC-EV Workflow | Key Quality / Regulatory Consideration |

|---|---|---|

| GMP-grade Human MSC Cell Bank | Starting material for production. Provides genetic stability and defined identity. | Must be qualified per ICH Q5D (Derivation, History, Testing). Traceable, non-xenogeneic origin preferred. |

| Xeno-free, Chemically-defined Cell Culture Medium | Supports expansion of MSCs without introducing animal-derived contaminants. | Eliminates risk from FBS-derived EVs and adventitious agents. Essential for clinical-grade production (EMA CAT guideline). |

| Serum Albumin (Human), GMP-grade | May be used as a stabilizer or medium component. | Sourced from approved vendors, with full traceability and viral safety data (ICH Q5A). |

| DNase I, RNase-free, GMP-grade | Treatment of conditioned media to reduce viscosity from cell debris DNA. | Must be well-characterized, low endotoxin. Validated for lack of adverse impact on EV yield/function. |

| Protease Inhibitor Cocktail | Added during conditioned media harvest to prevent EV protein degradation. | Composition should be defined. Avoids inhibitors that interfere with subsequent functional assays. |

| Size-Exclusion Chromatography (SEC) Columns | Critical for EV purification from soluble protein contaminants. | Column must be validated for EV separation efficiency, non-binding properties, and cleaned/sanitized per bioburden control (GMP). |

| Particle Size & Count Standard (e.g., Silica Beads) | Calibration of NTA or Flow Cytometry instruments for EV quantification. | Traceable to international standards (e.g., NIST). Required for assay qualification (ICH Q2). |

| EV Characterization Antibody Panel (CD9, CD63, CD81, etc.) | Confirmation of EV identity via flow cytometry (MISEV guidelines). | Critical reagents: require clonality, specificity testing, and lot-to-lot consistency. |

| LAL Endotoxin Assay Kit | Detection of Gram-negative bacterial endotoxins in final product. | Must be validated for use with the specific EV product (inhibition/enhancement testing per USP <85>, EP 2.6.14). |

| Reference Standard EV Material | Well-characterized EV batch used for assay system suitability and trending. | Ideally an in-house primary standard from a GMP-like process. Characterized for key attributes (Identity, Potency, Purity). |

Application Note: Integrating QbD into MSC-EV Process Development

Objective: To establish a systematic Quality by Design (QbD) framework for the development of a scalable, clinical-grade MSC-EV production process, ensuring critical quality attributes (CQAs) are met.

Key Concepts & Data:

- Quality Target Product Profile (QTPP): A predefined summary of the quality characteristics for MSC-EVs intended for clinical use.

- Critical Quality Attributes (CQAs): Physical, biochemical, or functional properties that must be within appropriate limits to ensure product safety and efficacy.

- Critical Process Parameters (CPPs): Process variables that directly impact CQAs and must be monitored and controlled.

Table 1: Exemplary QbD Elements for Clinical-Grade MSC-EV Production

| QbD Element | Definition & Example for MSC-EVs | Typical Target/Control Range |

|---|---|---|

| QTPP | Intended Use: Immunomodulation for Acute Respiratory Distress Syndrome (ARDS). | N/A |

| CQAs | Particle Concentration: EVs/µL. | > 5e8 EVs/µL (final product) |

| Size Distribution (Mean): nm by NTA. | 80 - 200 nm | |

| Purity (Protein/particle ratio): µg protein / 1e9 particles. | < 150 µg protein / 1e9 particles | |

| Potency Marker: IDO activity (nmol/hr/mg protein) or tetraspanin positivity (%) | > 80% CD63/CD81 positive | |

| Sterility: Bacterial/fungal growth. | No growth (compendial test) | |

| Critical Material Attributes (CMAs) | MSC Donor Age/Population Doublings: Influences EV yield and potency. | PDL < 15 |

| Serum-Free Media Lot: Impacts cell growth and EV secretion. | Qualified vendor, performance-tested lot | |

| CPPs | Cell Seeding Density: Cells/cm² at initiation of EV production. | 70-90% confluency at harvest |

| Hypoxia Conditioning: % O₂ during EV production phase. | 1-5% O₂ for 24-48h | |

| Harvest Time (Conditioned Media): Hours post-media change. | 48 ± 2 hours | |

| Tangential Flow Filtration (TFF) Shear Rate: s⁻¹. | Optimized to minimize aggregate formation |

Protocol 1.1: Establishing a Design Space for EV Harvesting

- Objective: Determine the optimal interaction between cell confluence at harvest and hypoxic conditioning time to maximize EV yield (CQA: particle concentration) while maintaining potency (CQA: IDO activity).

- Materials: Passage 5 human bone marrow-derived MSCs, qualified serum-free media, hypoxia chamber (1% O₂), normoxia incubator (21% O₂), nanoparticle tracking analyzer (NTA), HPLC for IDO (kynurenine) assay.

- Method:

- Seed MSCs in T-175 flasks at densities to achieve 60%, 80%, and 100% confluence at the start of harvest.

- Replace media with production media. For each density, expose flasks to either normoxia (21% O₂) or hypoxia (1% O₂).

- Collect conditioned media at 24h, 48h, and 72h time points for each confluence/O₂ combination (n=3 flasks per condition).

- Process conditioned media through sequential centrifugation (300 × g, 2000 × g) and 0.22 µm filtration.

- Concentrate and buffer exchange using a 100 kDa TFF system.

- Analyze concentrate for: a) Particle concentration and size (NTA), b) Total protein (BCA), c) IDO activity.

- Data Analysis: Use multivariate analysis (e.g., Response Surface Methodology) to model the relationship between CPPs (confluence, O₂ %, time) and CQAs. The operable region where all CQAs meet specifications defines the design space.

Diagram 1: QbD Framework for MSC-EV Process Development

Application Note: Implementing Risk Management (ICH Q9) in MSC-EV Workflows

Objective: To apply a formal risk management process to identify, analyze, evaluate, and control potential sources of variability and failure in MSC-EV manufacturing and testing.

Protocol 2.1: Failure Mode and Effects Analysis (FMEA) for EV Isolation

- Objective: Prioritize risks associated with the Tangential Flow Filtration (TFF) and Size Exclusion Chromatography (SEC) isolation steps.

- Method:

- Assemble Team: Process development scientist, analytical scientist, quality assurance.

- Define Process Steps: List each sub-step (e.g., TFF system setup, concentration, diafiltration, SEC column equilibration, fraction collection).

- Identify Failure Modes: For each step, brainstorm what could go wrong (e.g., TFF membrane fouling, incorrect buffer pH, SEC fraction mis-collection).

- Score Severity (S), Occurrence (O), Detection (D): Use a 1-10 scale. S: Impact on CQAs. O: Likelihood. D: Chance of detecting before release.

- Calculate RPN: Risk Priority Number = S × O × D.

- Plan Mitigations: For high RPN items, define corrective actions (e.g., implement in-line pH monitoring, validate cleaning-in-place protocol).

Table 2: FMEA Excerpt for MSC-EV Isolation Process

| Process Step | Potential Failure Mode | Potential Effect on CQAs | S | O | D | RPN | Mitigation Action |

|---|---|---|---|---|---|---|---|

| TFF Concentration | High shear rate | EV aggregation, loss of potency, increased size | 8 | 3 | 2 | 48 | Validate and fix optimal shear rate (CPP); implement sensor control. |

| Buffer Exchange | Incorrect diafiltration buffer pH | EV stability compromised, protein degradation | 9 | 2 | 6 | 108 | Use pre-qualified buffer bags; perform in-process pH check. |

| SEC Fraction Collection | Incorrect fraction window (too broad) | Low purity (soluble protein contamination) | 7 | 4 | 3 | 84 | Validate fraction collection based on UV/RI trace; automate collection. |

Diagram 2: ICH Q9 Risk Management Process Flow

Application Note: Ensuring Complete Traceability in MSC-EV Research

Objective: To establish a chain of identity and chain of custody from the originating mesenchymal stromal cell (MSC) donor through to the final MSC-EV batch, including all materials, processes, and data.

Protocol 3.1: Implementing a Unique Identifier (UID) System for EV Batches

- Objective: Generate a UID that links an EV batch to all its antecedents.

- Method:

- Donor/Source Cell ID: Assign a UID to the primary MSC donor/tissue (e.g.,

DON-BM-001). - Cell Bank ID: Assign a UID to each master/working cell bank derived (e.g.,

DON-BM-001-MCB-P5). - Production Run ID: Assign a UID to each EV production run, incorporating the cell bank ID and run number (e.g.,

EV-RUN-DON-BM-001-MCB-P5-024). - Material Linkage: Log all critical reagent lot numbers (media, supplements, columns) against the Production Run ID.

- Data Linkage: All analytical files (NTA, protein, potency) must be saved with the Production Run ID in the filename and metadata.

- Storage Linkage: Final product vials and retain samples must be labeled with the UID and stored in a location mapped in an inventory system.

- Donor/Source Cell ID: Assign a UID to the primary MSC donor/tissue (e.g.,

Table 3: Traceability Matrix for a Single MSC-EV Batch

| UID | Entity | Key Linked Attributes | Storage Location |

|---|---|---|---|

| DON-BM-001 | Bone Marrow Donor | Donor consent, age, screening tests | Donor file, secure server |

| DON-BM-001-MCB-P5 | Master Cell Bank (Passage 5) | Vial numbers, viability, sterility, identity (flow cytometry) | Liquid N2 Tank A, Rack 3 |

| MED-SFM-XX-123 | Serum-Free Media | Vendor, lot number, CoA, endotoxin test | -20°C Freezer F12 |

| EV-RUN-DON-BM-001-MCB-P5-024 | EV Production Batch | Harvest date, CPP logs (confluence, O2%), operator | 4°C Cold Room, Shelf B2 |

| DATA-EV-RUN-024-NTA | Analytical Result | NTA report file, instrument ID, analyst | LIMS Project "EV-ARDS" |

Diagram 3: Chain of Identity and Custody for MSC-EVs

The Scientist's Toolkit: Essential Reagents & Materials for GMP-Compliant MSC-EV Research

Table 4: Key Research Reagent Solutions for Clinical-Grade MSC-EV Workflows

| Item | Function & GMP Relevance | Example (for informational purposes) |

|---|---|---|

| Xeno-Free, Serum-Free MSC Media | Supports MSC expansion and EV production without animal-derived components, reducing pathogen risk and lot variability. Essential for clinical compliance. | StemMACS MSC EV-XF, TheraPEAK MSCGM-CD. |

| Defined Attachment Substrate | Provides a consistent, recombinant surface for MSC adhesion, replacing animal-sourced coatings like gelatin. Enhances process control. | CELLstart, Recombinant Human Vitronectin. |

| Biocompatible TFF Membranes | For gentle concentration and buffer exchange of conditioned media. Cassettes with appropriate molecular weight cut-offs (e.g., 100-300 kDa) are critical for EV yield and purity. | Pellicon Cassettes (100 kDa), mPES hollow fiber filters. |

| GMP-Grade Size Exclusion Columns | For high-resolution purification of EVs from soluble proteins. Pre-packed, sanitizable columns ensure reproducibility and reduce endotoxin/particle contamination. | qEVoriginal columns (Izon), HiPrep Sephacryl S-500 HR. |

| Particle & Protein Standards | Essential for calibrating analytical instruments (NTA, SEC, protein assays) to ensure accurate quantification of CQAs. | Silica microspheres (NTA), Protein Standard (BCA). |

| Mycoplasma Detection Kit | A validated, highly sensitive assay for detecting mycoplasma contamination in cell cultures and EV products. A mandatory release test. | MycoAlert PLUS (Lonza). |

| Endotoxin Detection Assay | A chromogenic LAL assay to quantify bacterial endotoxins in final EV preparations, a critical safety specification. | Endosafe Neogen (Charles River). |

| Tetraspanin Detection Antibodies | Fluorescently labelled, validated antibodies for characterizing EV surface markers (e.g., CD63, CD81, CD9) via flow cytometry (MACSQuant) or ELISA. | Anti-human CD63-APC, CD81-FITC. |

Within a Good Manufacturing Practice (GMP) framework for clinical-grade Mesenchymal Stromal Cell-derived Extracellular Vesicle (MSC-EV) production, the foundation lies in the rigorous characterization and standardization of the starting cellular material. Variability in MSC source directly impacts EV yield, cargo, and therapeutic potency. This document details critical application notes and protocols for donor screening, tissue origin selection, and Master Cell Bank (MCB) establishment to ensure a reproducible, safe, and efficacious MSC starting population.

Application Note: Donor Screening Criteria

Donor selection is the first critical control point. Comprehensive screening mitigates risks of adventitious agent transmission and ensures donor health parameters align with intended therapeutic use.

Table 1: Mandatory Donor Screening Assays

| Screening Category | Specific Test/Parameter | Acceptance Criteria | Rationale |

|---|---|---|---|

| Infectious Disease | HIV-1 & HIV-2 (RNA/PCR) | Non-reactive | Prevents viral contamination of cell bank. |

| Hepatitis B (HBsAg, Anti-HBc, HBV DNA) | Non-reactive | Prevents viral contamination. | |

| Hepatitis C (Anti-HCV, HCV RNA) | Non-reactive | Prevents viral contamination. | |

| Treponema pallidum (Syphilis) | Non-reactive | Ensures donor health status. | |

| Health & Genetics | Karyotype (G-banding) | Normal (46, XX or XY) | Ensures genomic stability. |

| Short Tandem Repeat (STR) Profiling | Completed for identity testing | Provides unique donor/cell line fingerprint. | |

| Mycoplasma (PCR/Culture) | Negative | Prevents microbial contamination. | |

| MSC Potency | In vitro trilineage differentiation (Adipogenic, Osteogenic, Chondrogenic) | Positive by staining & qPCR | Confirms MSC multipotency. |

| Immunosuppression Assay (e.g., T-cell proliferation) | >30% inhibition of proliferation | Confirms a key functional potency. | |

| Surface Marker Profile (Flow Cytometry) | ≥95% positive for CD73, CD90, CD105; ≤2% positive for CD34, CD45, HLA-DR | Confirms immunophenotype per ISCT criteria. |

Experimental Protocol: MSC Isolation & Initial Characterization from Tissue

Protocol 2.1: Explant Isolation and Culture of Bone Marrow-derived MSCs (BM-MSCs)

- Objective: To isolate and establish primary MSC cultures from bone marrow aspirate using the explant method.

- Materials:

- GMP-grade α-MEM medium, supplemented with 5% human platelet lysate (hPL), 1% L-glutamine, 1% penicillin/streptomycin.

- Phosphate-Buffered Saline (PBS), without Ca²⁺/Mg²⁺.

- GMP-grade trypsin/EDTA or recombinant trypsin.

- T-75 culture flasks.

- Sterile 100 µm cell strainers.

- Bone marrow aspirate (5-10 mL) from screened donor.

- Procedure:

- Dilute the bone marrow aspirate 1:2 with PBS.

- Slowly layer the diluted aspirate over an equal volume of Ficoll-Paque Premium in a 50 mL conical tube.

- Centrifuge at 400 x g for 30 minutes at room temperature with the brake OFF.

- Aspirate the mononuclear cell (MNC) layer at the interface and transfer to a new tube.

- Wash MNCs with 3x volume of PBS. Centrifuge at 300 x g for 10 minutes. Repeat wash.

- Resuspend cell pellet in complete medium. Pass through a 100 µm cell strainer.

- Seed cells at a density of 5 x 10⁴ cells/cm² in a T-75 flask.

- Incubate at 37°C, 5% CO₂. Perform first medium change at 72 hours to remove non-adherent cells, then change medium twice weekly.

- Passage cells at ~80% confluence using trypsin. This is designated as Passage 0 (P0).

Protocol 2.2: Immunophenotypic Characterization by Flow Cytometry

- Objective: To confirm MSC surface marker expression per ISCT guidelines.

- Materials:

- Flow cytometry buffer (PBS + 2% FBS).

- Antibody panel: CD73-APC, CD90-FITC, CD105-PE, CD45-PerCP, CD34-PE-Cy7, HLA-DR-BV421.

- Appropriate isotype controls.

- Flow cytometer with 488 nm and 633 nm lasers.

- Procedure:

- Harvest MSCs at P2-P3 using trypsin. Wash 2x with PBS. Count cells.

- Aliquot 1 x 10⁵ cells per tube (test and isotype controls).

- Resuspend cells in 100 µL flow buffer. Add recommended volume of antibody. Vortex gently.

- Incubate for 30 minutes at 4°C in the dark.

- Add 2 mL flow buffer, centrifuge at 300 x g for 5 minutes. Aspirate supernatant.

- Resuspend in 300 µL flow buffer. Analyze immediately on flow cytometer.

- Analysis: Gate on viable, single cells. Compare fluorescence to isotype controls. ≥95% positivity for CD73, CD90, CD105 and ≤2% positivity for CD34, CD45, HLA-DR is required.

Application Note: Tissue Origin Comparative Analysis

The tissue source influences MSC expansion potential, secretome, and immunomodulatory profile.

Table 2: Comparative Analysis of Common MSC Tissue Sources

| Parameter | Bone Marrow (BM) | Adipose Tissue (AT) | Umbilical Cord (UC) | Dental Pulp (DP) |

|---|---|---|---|---|

| Typical Yield (Cells per gram) | 5 x 10³ - 6 x 10³ | 5 x 10⁵ - 2 x 10⁶ | 1 x 10⁴ - 5 x 10⁴ | 1 x 10³ - 3 x 10³ |

| Population Doubling Time (Early passages) | ~40 hours | ~30 hours | ~25 hours | ~35 hours |

| Senescence Limit (Population doublings) | ~30-40 | ~40-50 | ~50-60 | ~30-40 |

| Key Secretome/EV Advantages | High angiogenic potential; robust immunomodulation. | High VEGF & HGF secretion; abundant source. | High proliferation; strong anti-inflammatory profile (TSG-6). | High neuroregenerative potential. |

| Key Challenges for GMP | Invasive harvest; donor age effects on potency. | Liposurgery variability; need for collagenase digestion. | Fetal tissue ethics/logistics; perinatal screening. | Limited starting material; heterogeneity. |

Protocol: Master Cell Bank (MCB) Generation & Qualification

Protocol 4.1: MCB Generation and Cryopreservation

- Objective: To create a characterized, homogeneous MCB from a validated MSC working cell bank (WCB) at low passage.

- Materials:

- MSCs at P3-P4 (from WCB).

- GMP-grade cryopreservation medium (e.g., 5% DMSO in hPL).

- Controlled-rate freezer.

- Cryogenic vials.

- Liquid nitrogen storage system.

- Procedure:

- Culture MSCs to 80% confluence. Harvest using trypsin and perform a viable cell count.

- Centrifuge at 300 x g for 5 minutes. Aspirate supernatant completely.

- Resuspend cell pellet in cold cryopreservation medium to a final concentration of 1-2 x 10⁶ cells/mL.

- Aliquot 1.0 mL per labeled cryovial.

- Place vials in a controlled-rate freezer: Cool at -1°C/min to -40°C, then at -10°C/min to -90°C.

- Transfer vials immediately to the vapor phase of liquid nitrogen for long-term storage.

- The MCB size should be sufficient for the entire product development lifecycle (e.g., 100-200 vials).

Protocol 4.2: MCB Release Testing

- Objective: To perform quality control tests on a representative vial from the MCB.

- Tests: Post-thaw viability (≥80%), sterility (bacteria/fungi, 14-day culture), mycoplasma (PCR), endotoxin (LAL, <0.5 EU/mL), identity (STR match to donor), purity (flow cytometry, per Table 1), and potency (e.g., trilineage differentiation or immunosuppression assay).

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Reagent Solutions for GMP-Compliant MSC Source Work

| Item | Function/Application | Key Consideration for GMP |

|---|---|---|

| Human Platelet Lysate (hPL) | Serum replacement for xeno-free MSC expansion. | Must be gamma-irradiated, pathogen-tested, and from accredited donors. Quality impacts expansion and EV profile. |

| GMP-Grade Trypsin | Enzymatic detachment of adherent MSCs. | Recombinant, animal-origin-free versions reduce contamination risks and lot variability. |

| Defined Cryopreservation Medium | Long-term storage of MCB. | Chemically defined, DMSO-containing, with optimized carrier protein. Ensures post-thaw viability and function. |

| Flow Cytometry Antibody Panel | Immunophenotypic characterization. | Clone specificity and validation for human MSCs is critical. Use GMP-grade or RUO antibodies with strict validation protocols. |

| Trilineage Differentiation Kits | Assessment of multipotency. | Use GMP-grade or well-validated, defined media components. Standardize quantification (e.g., qPCR for lineage genes). |

| PCR Mycoplasma Detection Kit | Screening for mycoplasma contamination. | Must have high sensitivity (<10 CFU/mL). Used for in-process and MCB release testing. |

Visualizations: Workflow and Strategy

Within a thesis on GMP standards for clinical-grade Mesenchymal Stromal Cell-Extracellular Vesicle (MSC-EV) production, defining Critical Quality Attributes (CQAs) is paramount. CQAs are measurable properties that directly link to product safety, efficacy, and quality. For MSC-EVs as investigational therapeutic agents, four core CQA categories emerge: Identity, Purity, Potency, and Safety. This document provides detailed application notes and protocols for their assessment, forming the analytical bedrock for GMP-compliant research and development.

CQA 1: Identity

Identity confirms the product is derived from MSCs and is indeed an EV preparation. It involves source cell characterization and vesicle-specific profiling.

Application Notes: Identity assays verify the presence of expected markers and the physical attributes of EVs. A multi-parametric approach is required, as no single marker is definitive.

Protocol 1.1: Nanoparticle Tracking Analysis (NTA) for Size and Concentration

- Objective: Determine particle size distribution and concentration in particles/mL.

- Materials: Purified EV sample in PBS, syringe, 0.1 µm filtered PBS, NTA instrument (e.g., Malvern NanoSight NS300).

- Procedure:

- Dilute EV sample in 0.1 µm filtered PBS to achieve 20-100 particles per frame.

- Load sample into instrument syringe.

- Capture five 60-second videos at camera level 13-16 and detection threshold 5.

- Process videos with instrument software to calculate mode and mean diameter (D50, D90) and particle concentration.

- Data Interpretation: Expect a mode size between 70-200 nm. A primary peak outside this range may indicate impurity or aggregation.

Protocol 1.2: Transmission Electron Microscopy (TEM) for Morphology

- Objective: Visualize cup-shaped vesicle morphology.

- Materials: Formvar/carbon-coated grids, purified EV sample, 2% uranyl acetate, TEM.

- Procedure:

- Load 5-10 µL of EVs onto grid for 20 min.

- Wash with distilled water, negative stain with 2% uranyl acetate for 1 min.

- Image using TEM at 80-100 kV.

Protocol 1.3: Surface Marker Profiling via Flow Cytometry (Capture Bead Assay)

- Objective: Semi-quantitatively detect presence of EV tetraspanins (CD9, CD63, CD81) and MSC markers (CD29, CD44, CD73, CD90, CD105).

- Materials: Aldehyde/sulfate latex beads (4% w/v, 4 µm), purified EVs, PBS-BSA (0.1%), antibodies against target antigens, flow cytometer.

- Procedure:

- Dilute beads 1:1000 in PBS, mix with equal volume of EV sample, incubate 15 min.

- Add PBS-BSA to 2 mL final, incubate 90 min at RT with rotation.

- Block with glycine (100 mM) for 30 min.

- Wash beads, incubate with fluorescent-conjugated primary antibodies for 40 min.

- Analyze on flow cytometer. Use isotype and bead-only controls.

Table 1: Identity CQA Specifications

| Attribute | Recommended Method | Target Specification | Justification |

|---|---|---|---|

| Size Distribution | Nanoparticle Tracking Analysis (NTA) | Mode: 70-200 nm | Characteristic of small EVs (exosomes). |

| Morphology | Transmission Electron Microscopy (TEM) | Cup-shaped vesicles observed | Confirms EV structure. |

| Concentration | NTA or Tunable Resistive Pulse Sensing (TRPS) | Report particles/mL & µg protein | Batch consistency metric. |

| EV Surface Markers | Flow Cytometry (Bead-based) | Positive for ≥2 of: CD9, CD63, CD81 | MISEV2018 guidelines. |

| Parent MSC Markers | Flow Cytometry (Bead-based) | Positive for ≥3 of: CD73, CD90, CD105, CD44 | Confirms MSC origin. |

Diagram Title: Analytical Workflow for Identity CQAs

CQA 2: Purity

Purity assesses the degree of contamination from non-EV components, primarily residual proteins from culture medium or cell debris.

Application Notes: Purity is a ratio, not an absolute measure. Key metrics include particle-to-protein ratio and assessment of specific contaminants like lipoproteins or apoptotic bodies.

Protocol 2.1: Particle-to-Protein Ratio

- Objective: Calculate a high-fidelity purity index (particles/µg protein).

- Materials: EV sample, BCA or Micro BCA Protein Assay Kit, NTA instrument.

- Procedure:

- Determine particle concentration (particles/mL) via NTA (Protocol 1.1).

- Determine total protein concentration (µg/mL) via BCA assay, using BSA standard curve.

- Calculate ratio: (Particles/mL) / (Protein µg/mL).

- Data Interpretation: Higher ratios (>1e10 particles/µg) suggest purer EV preparations with less co-isolated soluble protein.

Protocol 2.2: Western Blot for Negative Markers

- Objective: Detect absence of common contaminant proteins.

- Materials: EV lysate, SDS-PAGE gel, antibodies against Apolipoprotein A1/ B (lipoproteins), Calnexin/GM130 (endoplasmic reticulum/Golgi).

- Procedure:

- Load 10-20 µg EV protein and parent MSC whole cell lysate (positive control) per lane.

- Perform SDS-PAGE and transfer to PVDF membrane.

- Block, incubate with primary antibody (e.g., anti-ApoA1, 1:1000) overnight.

- Incubate with HRP-conjugated secondary, develop.

- Data Interpretation: Contaminant markers should be absent or significantly reduced (>90%) in EV lysate compared to cell lysate.

Table 2: Purity CQA Specifications

| Attribute | Recommended Method | Target Specification | Justification |

|---|---|---|---|

| Particle-to-Protein Ratio | NTA + BCA Assay | > 3.0 x 10¹⁰ particles/µg | Indicator of low soluble protein contamination. |

| Negative Markers | Western Blot | Absent or minimal: Apolipoprotein A1/B, Calnexin | Absence of lipoprotein & intracellular organelle contamination. |

| Lipoprotein Contamination | SEC-UV/Vis (A280/A260) | A280/A260 ratio > 0.6 | Lower ratio suggests nucleic acid or lipoprotein carryover. |

CQA 3: Potency

Potency is the quantitative measure of biological activity linked to the relevant therapeutic mechanism of action (MoA).

Application Notes: Potency assays must be mechanism-based, quantitative, and validated. Common MoAs for MSC-EVs include immunomodulation, angiogenesis, and tissue repair.

Protocol 3.1: T-Cell Proliferation Suppression Assay (Immunomodulation)

- Objective: Quantify EV ability to suppress activated immune cell proliferation.

- Materials: Human PBMCs, CFSE dye, anti-CD3/CD28 activation beads, purified MSC-EVs, flow cytometer.

- Procedure:

- Isolate CD3+ T-cells from PBMCs, label with CFSE (5 µM).

- Activate cells with anti-CD3/CD28 beads.

- Co-culture with MSC-EVs (e.g., 1e9 particles/well) for 72-96 hrs.

- Analyze CFSE dilution via flow cytometry. Calculate % suppression vs. activated control without EVs.

- Data Interpretation: A dose-dependent suppression of T-cell proliferation indicates immunomodulatory potency.

Protocol 3.2: Endothelial Tube Formation Assay (Angiogenesis)

- Objective: Measure pro-angiogenic activity.

- Materials: HUVECs, Matrigel, purified MSC-EVs, tubule imaging system.

- Procedure:

- Seed HUVECs on Matrigel-coated plates.

- Treat with MSC-EVs (e.g., 1e10 particles/mL) in endothelial basal medium.

- Incubate 4-8 hrs, fix, stain with calcein-AM.

- Image and quantify total tubule length, number of nodes.

- Data Interpretation: Increased tubule formation vs. vehicle control indicates angiogenic potency.

Table 3: Example Potency CQA Specifications

| Therapeutic Indication | Potency Assay | Quantitative Readout | Target Specification (Example) |

|---|---|---|---|

| GvHD / Inflammation | T-Cell Proliferation Assay | % Suppression of proliferation | IC₅₀ ≤ 1 x 10⁹ particles/mL |

| Myocardial Infarction | Endothelial Tube Formation | % Increase in total tubule length | ED₅₀ ≤ 5 x 10⁹ particles/mL |

| Wound Healing | Fibroblast Migration (Scratch) | % Wound closure at 24h | ≥40% enhancement vs. control |

Diagram Title: Example EV Potency Pathway in Tissue Repair

CQA 4: Safety

Safety CQAs ensure the product is free from harmful contaminants that pose risk to patients, including endotoxins, mycoplasma, and replicating viruses.

Protocol 4.1: Endotoxin Testing (LAL Assay)

- Objective: Detect and quantify bacterial endotoxins.

- Materials: EV sample, Kinetic Chromogenic LAL Assay kit, pyrogen-free tubes, microplate reader.

- Procedure:

- Dilute EV sample in endotoxin-free water.

- Follow kit protocol: mix sample with LAL reagent, incubate at 37°C.

- Add chromogenic substrate, measure absorbance at 405 nm over time.

- Calculate EU/mL from standard curve.

- Data Interpretation: Must meet limit of <5 EU/kg/hr for parenteral administration (FDA guideline).

Protocol 4.2: Sterility Testing (Bacteriostasis/Fungistasis)

- Objective: Demonstrate absence of viable bacteria and fungi.

- Materials: EV sample, Fluid Thioglycollate Medium (FTM), Soybean-Casein Digest Medium (SCDM).

- Procedure:

- Inoculate 10 mL FTM (for aerobes/anaerobes) and SCDM (for fungi) with 1 mL of EV product.

- Incubate FTM at 30-35°C and SCDM at 20-25°C for 14 days.

- Observe daily for turbidity, indicating microbial growth.

- Data Interpretation: No growth in media after 14 days indicates sterility.

Table 4: Safety CQA Specifications

| Attribute | Recommended Method | Target Specification | Justification |

|---|---|---|---|

| Endotoxin | Limulus Amebocyte Lysate (LAL) Assay | < 2.0 EU/mL (or per dose) | Compliance with parenteral drug standards. |

| Sterility | Direct Inoculation / Membrane Filtration | No growth in 14 days | USP <71>; ensures absence of microbiological contamination. |

| Mycoplasma | PCR-based or Culture-based Assay | Negative | Essential for products derived from cell culture. |

| Residual Host Cell DNA | qPCR (e.g., Alu-repeat) | < 10 ng/dose (WHO recommendation) | Minimizes oncogenic/immunogenic risk. |

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function & Application | Example Vendor/Product |

|---|---|---|

| qEV size-exclusion columns | Isolate EVs with high purity and recovery from conditioned medium. | Izon Science, qEVoriginal 35nm |

| Total Exosome Isolation Reagent | Precipitation-based EV enrichment from serum-free or serum-containing media. | Thermo Fisher Scientific, 4478359 |

| CD9/CD63/CD81 Antibody Cocktail | Detection of EV tetraspanins for characterization via flow cytometry or WB. | System Biosciences, EXOAB-KIT-1 |

| Recombinant Human TGF-β1 | Positive control for potency assays involving SMAD signaling pathways. | PeproTech, 100-21 |

| Lonza Kinetic-QCL LAL Kit | Sensitive, quantitative detection of endotoxin for safety testing. | Lonza, 50-650U |

| MycoAlert Detection Kit | Rapid, bioluminescent detection of mycoplasma contamination. | Lonza, LT07-318 |

| HUVECs & EGM-2 BulletKit | Primary cells and optimized media for angiogenesis potency assays. | Lonza, CC-2517 & CC-3162 |

| CellTrace CFSE Cell Proliferation Kit | Fluorescent dye for tracking and quantifying lymphocyte proliferation. | Thermo Fisher Scientific, C34554 |

From Flask to Vial: Step-by-Step GMP Methods for Scalable MSC-EV Production

The transition from research to clinical-grade mesenchymal stromal cell (MSC) production for extracellular vesicle (EV) harvest requires strict adherence to Good Manufacturing Practice (GMP). This mandates a shift from open, xeno-containing systems to closed, automated, and chemically defined platforms. The core triad for GMP-compliant expansion comprises: (1) Closed Processing Systems to minimize contamination, (2) Xeno-Free/Serum-Free Media to eliminate undefined components and batch variability, and (3) Bioreactor Technologies for scalable, monitored, and reproducible culture. Implementing this triad is critical for generating MSC-EVs with consistent quality, potency, and safety profiles for therapeutic applications.

Key Protocols and Methodologies

Protocol 2.1: Seeding and Expansion in a Closed System Stirred-Tank Bioreactor

- Objective: To expand MSCs from passage 2 (P2) master cell bank vials to harvest-ready quantities in a GMP-compliant, controlled bioreactor.

- Materials: See Scientist's Toolkit (Table 1).

- Pre-Culture: Thaw a P2 MSC vial in a closed thawing device. Transfer cells to a pre-coated T-flask using a sterile tubing welder/connector. Expand in xeno-free medium in a closed, multi-layer flask stack system until sufficient inoculum is achieved (e.g., 1–2 x 10^8 cells).

- Bioreactor Setup & Seeding:

- Sterilize the bioreactor vessel (e.g., 2L working volume) in situ via autoclave or SIP (Steam-In-Place).

- Connect all media, harvest, and sampling lines via sterile connectors within a closed pathway.

- Prime the system with pre-warmed, equilibrated xeno-free medium.

- Detach cells from flask stacks using a closed-system detachment device and transfer cell suspension to the bioreactor inoculum bag via peristaltic pump.

- Seed cells into the bioreactor at a density of 1–2 x 10^4 cells/cm² (microcarrier surface area) or 2–4 x 10^5 cells/mL (aggregate culture).

- Process Parameters:

- Temperature: 37°C ± 0.2°C

- pH: 7.2–7.4 (controlled via CO₂ and base addition)

- Dissolved Oxygen (DO): 30–50% air saturation (cascaded control with O₂, N₂, and air)

- Agitation: 60–100 rpm (intermittent or continuous, depending on microcarrier type) to prevent aggregation and ensure nutrient homogeneity.

- Feeding & Harvest: Perform medium exchange (50–80%) every 48-72 hours via a closed drain-and-fill protocol. Monitor glucose/lactate to guide feeding strategy. At harvest (typically day 7-10), stop agitation, allow microcarriers/cell aggregates to settle, and drain spent medium. Wash with PBS, then add dissociation reagent. Transfer cell slurry to a closed harvest bag via in-line filtration to remove microcarriers.

Protocol 2.2: In-Process Quality Control (QC) Testing

- Objective: To monitor critical quality attributes (CQAs) during expansion.

- Sampling: Use aseptic, closed sampling systems integrated into the bioreactor line.

- Daily Tests:

- Cell Count & Viability: Use an automated cell counter with trypan blue exclusion. Withdraw a 1 mL sample, lyse microcarriers if necessary, and analyze.

- Metabolite Analysis: Use a blood gas/biochemistry analyzer for daily glucose, lactate, and glutamine measurement from 0.5 mL supernatant.

- Microbiology: Inoculate 10 mL samples into BacT/ALERT culture bottles for rapid sterility testing.

- Endpoint Tests (Pre-Harvest):

- Identity: Analyze surface markers (CD73+, CD90+, CD105+, CD45-, CD34-, HLA-DR-) via flow cytometry using a closed-tube staining system.

- Potency: Measure immunosuppressive capacity via a closed-system co-culture assay (e.g., inhibition of PHA-stimulated PBMC proliferation) or cytokine secretion profile (IDO, PGE2).

- Karyotyping: Send a cell sample for G-band karyotype analysis to confirm genetic stability.

Table 1: Comparison of Expansion Platforms for MSCs

| Platform | Max Scale (Cells) | Volumetric Productivity (Cells/mL/day) | Key Process Control Parameters | Suitability for GMP EV Production |

|---|---|---|---|---|

| Multi-layer Flasks | 1–2 x 10^9 | 1–3 x 10^4 | Temperature, CO₂ | Low-scale seed train; not final expansion |

| Fixed-bed Bioreactor | 5 x 10^9 | 2–5 x 10^4 | pH, DO, Flow Rate | High; integrated harvesting, good for adherent cells |

| Stirred-Tank w/ Microcarriers | 1 x 10^11 | 2–6 x 10^4 | pH, DO, Agitation, Temperature | Very High; highly scalable, proven in industry |

| Vertical-Wheel Bioreactor | 5 x 10^10 | 3–8 x 10^4 | pH, DO, Shear Stress | High; low-shear, suitable for aggregates & microcarriers |

Table 2: Key Performance Indicators in Xeno-Free Media vs. FBS-Containing Media

| Parameter | FBS-Based Media (Typical Range) | Xeno-Free/Serum-Free Media (Typical Range) | Impact on MSC-EV Production |

|---|---|---|---|

| Population Doubling Time (hrs) | 30–48 | 24–40 | Faster expansion may alter EV miRNA cargo. |

| Max Cumulative Population Doublings | 25–35 | 20–30 | Genetic stability threshold must be defined for EV consistency. |

| CD Marker Expression (% positive) | >95% (Tri-positive) | >95% (Tri-positive) | Confirms identity is maintained. |

| Immunosuppressive Activity (e.g., % T-cell inhibition) | 60–80% | 65–85% | Potency must be maintained or enhanced. |

| EV Yield (Particles/Cell) | 1,000–5,000 | 2,000–8,000 | Xeno-free media can enhance specific productivity. |

Diagrams

Title: GMP MSC Expansion Workflow for EV Production

Title: Bioreactor Process Control Loop

The Scientist's Toolkit: Research Reagent Solutions

Table 1: Essential Materials for GMP-Compliant MSC Expansion

| Item | Function in Protocol | Example Product/Category | Critical GMP Attribute |

|---|---|---|---|

| Xeno-Free MSC Medium | Provides defined nutrients & growth factors for proliferation. | StemMACS MSC XF, PPRF-msc6, TheraPEAK MSCGM-CD | Chemically defined, animal component-free, TSE/BSE-free, GMP-manufactured. |

| Human-Derived Attachment Factor | Coats surfaces for cell adhesion in place of FBS. | Recombinant Human Vitronectin, Laminin-521, Collagen I (Human) | Defined, pathogen-tested, xeno-free origin. |

| Microcarriers | Provides high surface area for adherent growth in stirred-tank bioreactors. | Solohill PrimeSurface, Cytodex 3, Plastic Porous Microcarriers. | Sterile, non-animal derived, validated for compatibility with xeno-free media. |

| Closed System Connectors | Enables aseptic connections between bags, bioreactors, and tubing. | Colder AseptiQuik, CPC Quick Disconnect, Sterile Welding. | Sterility assurance, steam-sterilizable, validated for zero bioburden ingress. |

| Single-Use Bioreactor | Pre-assembled, sterile culture vessel for scalable expansion. | Mobius (Merck), Xcellerex (Cytiva), BIOSTAT STR (Sartorius). | Eliminates cleaning validation, integrated sensors, scalable from 1L to 2000L. |

| In-Process Monitoring System | Measures critical parameters (pH, DO, Glucose) in real-time. | BioProfile FLEX2, SGA (DASGIP), Raman Spectroscopic Probes. | PAT (Process Analytical Technology) enabler, supports quality by design (QbD). |

| Closed Harvest System | Filters cells from microcarriers and concentrates harvest. | kSep or Centritech closed centrifugation, in-line depth filtration. | Maintains closed processing, reduces shear stress on cells for optimal EV release. |

The translation of Mesenchymal Stromal Cell-derived Extracellular Vesicles (MSC-EVs) from research tools to clinical-grade therapeutics requires adherence to Good Manufacturing Practice (GMP) principles. Within this broader thesis framework, this document provides detailed Application Notes and Protocols focusing on the upstream optimization of EV biogenesis. Critical input parameters—cell conditioning strategies and culture physicochemical environment—directly influence the yield, purity, and functional potency of the EV product, impacting downstream processing and final compliance with GMP standards for identity, safety, and efficacy.

Application Notes: Key Conditioning Strategies & Parameters

Optimizing EV biogenesis involves manipulating the cellular microenvironment to modulate endosomal sorting complexes required for transport (ESCRT)-dependent and -independent pathways, ceramide-mediated budding, and cellular stress responses. The following parameters are critical.

Table 1: Conditioning Strategies for Enhancing MSC-EV Biogenesis & Potency

| Strategy Category | Specific Condition | Typical Parameters / Reagents | Proposed Effect on EV Biogenesis & Cargo | Key Considerations for GMP Translation |

|---|---|---|---|---|

| Hypoxia | Reduced O2 tension | 1-5% O2 for 24-72h | ↑ EV yield via HIF-1α activation; ↑ angiogenic & immunomodulatory miRNAs. | Requires validated, calibrated incubators; process consistency is critical. |

| Serum Deprivation | Nutrient Stress | Serum-free medium for 24-48h | ↑ EV release as stress response; alters lipid and protein cargo. | Risk of increased apoptosis; must define optimal window to balance yield and cell health. |

| Small Molecule Induction | ESCRT/Pathway Modulators | GW4869 (nSMase2 inhibitor) - Note: used for inhibition studies. Trehalose, Dimethyloxalylglycine (DMOG). | Inhibition: Used as a negative control. Induction: Trehalose induces autophagy-EV crosstalk; DMOG stabilizes HIF-1α. | Reagent purity (e.g., DMSO quality); need for removal during downstream processing. |

| 3D Culture & Scaffolds | Spheroids/Bioreactors | Low-attachment plates, microcarriers, hollow-fiber bioreactors. | Mimics niche, ↑ cell-cell contact; ↑ EV yield and stemness-related cargo vs. 2D monolayers. | Scalability; extraction complexity; potential for contaminating materials (e.g., microcarrier debris). |

| Cytokine/Priming | Inflammatory Priming | IFN-γ, TNF-α, LPS (low dose) for 6-24h. | ↑ EV immunomodulatory cargo (e.g., PD-L1, IDO); shifts EV function towards anti-inflammatory. | Defining "Clinical-Grade" cytokine sources; exact priming conditions must be standardized. |

Table 2: Critical Physicochemical Culture Parameters

| Parameter | Optimal / Tested Range | Impact on EV Biogenesis | Monitoring & Control for GMP |

|---|---|---|---|

| pH | 7.2 - 7.6 | Deviations alter membrane fluidity & ESCRT function; can induce stress response. | In-line sensors in bioreactors; buffering capacity of medium must be defined. |

| Temperature | 37°C ± 0.5°C | Crucial for membrane lipid ordering and enzyme kinetics; lower temps may inhibit budding. | Continuous monitoring with alarms; uniformity mapping of incubators/chambers. |

| Dissolved O2 (DO) | Varies by strategy (e.g., 5% for hypoxia). | Directly regulates HIF signaling pathways; affects mitochondrial function and redox cargo. | Calibrated DO probes; control via gas mixing in bioreactors. |

| Glucose/Lactate | Glucose: Maintain >1 g/L; Lactate: Monitor accumulation. | Nutrient exhaustion stresses cells; high lactate can inhibit proliferation and alter EV release. | Off-line analyzers or in-line biosensors; fed-batch strategies to maintain levels. |

| OsmoMolarity | 280 - 320 mOsm/kg | Hyperosmotic stress can enhance EV release via ESCRT-III activation. | Must be tightly controlled; affected by media supplements and metabolite shifts. |

Detailed Experimental Protocols

Protocol 1: Optimization of Hypoxic Conditioning for MSC-EVs Objective: To produce a high yield of EVs with enhanced angiogenic cargo from human bone marrow-derived MSCs under hypoxic conditions. Materials: GMP-grade MSCs (P3-P5), validated serum-free MSC medium, triple-gas incubator (O2, CO2, N2 control), PBS, 0.22 µm PES filters, evLY-64 EV labeling kit, nanoparticle tracking analysis (NTA) instrument, BCA protein assay kit. Procedure:

- Cell Preparation: Seed MSCs at 5,000 cells/cm² in T-225 flasks. Expand to 70-80% confluence in normoxia (37°C, 21% O2, 5% CO2).

- Conditioning: Replace medium with fresh, pre-warmed, serum-free medium.

- Experimental Group: Transfer flasks to hypoxic incubator set to 1% O2, 5% CO2, balance N2.

- Control Group: Maintain in normoxic incubator (21% O2, 5% CO2).

- Conditioned Media (CM) Harvest: After 48 hours, collect CM from both groups.

- CM Processing: Centrifuge CM at 2,000 x g for 30 min at 4°C to remove cells. Transfer supernatant and centrifuge at 10,000 x g for 45 min at 4°C to remove debris. Filter supernatant through a 0.22 µm PES filter.

- EV Isolation: Concentrate EV-containing filtrate using tangential flow filtration (TFF) with a 100 kDa cutoff membrane, followed by size-exclusion chromatography (SEC) using qEVoriginal columns.

- Analysis:

- Yield: Use NTA to determine particle concentration (particles/mL) and mode size.

- Protein: Perform BCA assay on SEC fractions.

- Potency Marker: Analyze EV samples via western blot for HIF-1α-induced miRNAs (e.g., miR-210) by RT-qPCR.

Protocol 2: Monitoring and Controlling Physicochemical Parameters in a Bioreactor Objective: To maintain culture parameters within defined limits during EV production in a stirred-tank bioreactor. Materials: Benchtop bioreactor system (with pH, DO, temperature probes), MSC microcarriers, perfusion or fed-batch medium set, base (e.g., NaHCO3) and acid (e.g., CO2) for pH control, N2/O2/CO2 gas tanks, offline blood gas/glucose analyzer. Procedure:

- Bioreactor Setup & Calibration: Calibrate pH and DO probes according to manufacturer instructions. Set initial parameters: pH=7.4 (deadband ±0.1), DO=50% air saturation (or target for hypoxia), Temperature=37.0°C.

- Inoculation: Seed MSCs onto microcarriers and transfer to bioreactor vessel.

- Process Control:

- pH: Controlled via automatic addition of CO2 (to lower pH) or base (to raise pH).

- DO: Maintained by cascading control of stirrer speed (primary) and gas blending (secondary, e.g., N2/O2 mix).

- Temperature: Controlled by heated jacket.

- Sampling & Feeding: Take 5 mL samples every 12 hours for offline analysis of glucose, lactate, and osmolality. Implement a perfusion or bolus feed strategy based on glucose consumption rate to maintain glucose >1 g/L.

- Harvest Initiation: Begin continuous harvest of conditioned medium via an overflow filter when cell viability remains >90% and glucose consumption stabilizes. Process harvested medium immediately through downstream clarification (as in Protocol 1, Step 4).

Visualizations (Generated via Graphviz DOT Language)

Diagram 1: Key Signaling Pathways in EV Biogenesis Modulation

Title: Signaling Pathways in EV Biogenesis Modulation

Diagram 2: GMP Workflow for Conditioning & EV Production

Title: GMP Workflow for Conditioned EV Production

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for EV Biogenesis Optimization Research

| Reagent / Material | Supplier Examples | Function in EV Research | GMP-Translation Consideration |

|---|---|---|---|

| GMP-grade MSC Medium (Xeno-free) | Thermo Fisher, Lonza, Merck | Provides defined, consistent, animal-origin-free expansion of clinical-grade MSCs. | Essential; formulation must be fully disclosed and compliant. |

| Triple-Gas Incubator | Baker, Thermo Fisher | Precise control of O2, CO2, and N2 for reproducible hypoxic conditioning studies. | Requires IQ/OQ/PQ validation; continuous data logging. |

| Serum Replacement / EV-Depleted FBS | Thermo Fisher, System Biosciences | Provides growth factors while minimizing contaminating bovine EV background in conditioned media. | Must be thoroughly characterized; lot-to-lot consistency is critical. |

| GW4869 | Cayman Chemical, Sigma | Inhibits neutral sphingomyelinase 2 (nSMase2), used as a critical negative control to demonstrate ceramide-dependent EV biogenesis. | Research tool only; not for use in clinical production. Purity for reliable results. |

| Nanoparticle Tracking Analyzer (NTA) | Malvern Panalytical, Particle Metrix | Gold-standard for determining EV particle concentration and size distribution in suspension. | Key QC instrument; requires strict SOPs and reference standards for calibration. |

| Size-Exclusion Chromatography (SEC) Columns (qEV) | Izon Science | Gentle, size-based separation of EVs from soluble proteins and aggregates for high-purity isolates. | Columns are for single-use; scalable GMP-compatible alternatives (e.g., hollow fiber + FPLC) needed. |

| CD63/CD81/CD9 ELISA/ MACSPlex Exosome Kit | System Biosciences, Miltenyi Biotec | Multiplexed capture and analysis of EV surface epitopes for phenotypic characterization. | Assay suitability must be confirmed for MSC-EVs; used for identity testing. |

| Tangential Flow Filtration (TFF) System | Repligen, Spectrum Labs | Scalable concentration and buffer exchange of large volumes of conditioned media. | Core GMP technology; material compatibility (silicon-free) and sanitization validation required. |

Within the development of clinical-grade Mesenchymal Stromal Cell-derived Extracellular Vesicles (MSC-EVs), the initial harvesting and clarification steps are critical determinants of yield, purity, and compliance with Good Manufacturing Practice (GMP). Conditioned media (CM) is the starting material containing the EV product of interest, alongside cellular debris, apoptotic bodies, and soluble proteins. Scalable, closed-system methods for CM collection and primary clarification are essential to ensure process consistency, minimize batch-to-batch variability, and reduce the risk of contamination—core tenets of GMP manufacturing for therapeutic applications.

Application Notes: Scalable Collection Strategies

Harvest Parameters & Conditioning

Optimal CM collection balances MSC health, EV yield, and the minimization of impurities. Key parameters are summarized in Table 1.

Table 1: Optimization Parameters for Conditioned Media Harvesting

| Parameter | Typical Range (for MSC-EVs) | Rationale & GMP Consideration |

|---|---|---|

| Cell Confluence at Harvest | 70-90% | Prevents over-confluence-induced stress/apoptosis, reducing contaminating debris. Must be standardized. |

| Serum Deprivation Period | 24-48 hours | Uses EV-depleted serum or serum-free media to reduce bovine EV contaminants. Requires pre-qualified media lots. |

| Conditioning Time | 24-72 hours | Longer times increase yield but risk nutrient depletion and cell death. Must be validated for each cell line. |

| Collection Temperature | 2-8°C | Slows metabolic activity and protease function, preserving EV integrity post-secretion. |

| Bioreactor vs. Flask | Microcarriers/Suspension vs. 2D Layers | Scalable bioreactors (e.g., fixed-bed, hollow fiber) enable continuous harvest, aligning with large-scale GMP needs. |

Primary Clarification Techniques

Initial clarification removes cells and large debris. Scalability and closed-processing are paramount.

Table 2: Comparison of Primary Clarification Methods

| Method | Throughput | EV Recovery Estimate* | Suitability for GMP Scale-Up | Key Limitation |

|---|---|---|---|---|

| Low-Speed Centrifugation | Medium | ~95-100% | Low; open handling risks. Simple but not easily closed for large volumes. | Poor removal of small debris/apoptotic bodies. |

| Depth Filtration | High | ~85-95% | High; integrates into closed single-use systems. | Filter adsorption can cause EV loss; requires validation. |

| Tangential Flow Filtration (TFF) | High | ~90-98% | Very High; ideal for continuous processing & diafiltration. | Initial set-up complexity; potential shear stress. |

| Sequential Filtration (e.g., 5µm → 0.8µm) | Medium-High | ~80-90% | Medium; uses disposable filters in series. | Multiple steps increase adsorption loss points. |

*Recovery estimates are system-dependent and must be empirically determined.

Detailed Protocols

Protocol 3.1: Scalable Harvest from Multilayer Flasks with Depth Filtration

Objective: To collect and primarily clarify CM from MSCs grown in Cell Factory systems.

Materials (Research Reagent Solutions):

- Multilayer Cell Factories (e.g., 10-layer): For scalable 2D MSC expansion.

- GMP-grade, EV-depleted/XF Serum-Free Media: Pre-qualified lot to reduce contaminant load.

- Peristaltic Pump & Single-Use Tubing Set: Enables closed fluid transfer.

- Single-Use Depth Filter Capsule (e.g., 5-10 µm pore size): For inline primary clarification.

- Temperature-Controlled Collection Vessel: Maintains 2-8°C.

Methodology:

- Media Exchange & Conditioning: Aspirate growth media from confluent (80%) MSCs. Wash twice with DPBS. Add pre-warmed, EV-depleted conditioning media.

- Incubate: Condition cells for 48 hours at 37°C, 5% CO₂.

- Harvest (Closed System): a. Connect the Cell Factory outlet to the peristaltic pump tubing. b. Connect the pump outlet to the inlet of the pre-primed depth filter capsule. c. Connect the filter outlet to a sterile, chilled (4°C) collection bag. d. Pump CM from the Cell Factory, through the depth filter, into the collection bag. Maintain a controlled, low shear flow rate (e.g., 100 mL/min).

- Immediate Processing: Process clarified CM for secondary concentration/purification (e.g., TFF, UC) within 24 hours, storing at 4°C if necessary.

Protocol 3.2: Continuous Harvest and Clarification Using Tangential Flow Filtration (TFF)

Objective: To enable continuous CM harvest and clarification from a bioreactor system.

Materials (Research Reagent Solutions):

- Hollow Fiber or Fixed-Bed Bioreactor: For adherent MSC culture at scale.

- TFF System with 500 kDa - 0.8 µm MWCO/Pore Cassette: For simultaneous clarification and concentration.

- pH & Metabolite Sensors: For real-time monitoring of conditioning media.

- Feed and Permeate Collection Bags: Single-use, sterile.

Methodology:

- System Set-Up: Configure the bioreactor in a feed-and-bleed mode. Connect the harvest line to the TFF system's feed port. The retentate line returns to the bioreactor or a holding bag; the permeate line is the clarified CM product.

- Continuous Operation: a. Continuously pump fresh conditioning media into the bioreactor at a defined rate (e.g., 1 reactor volume per day). b. Simultaneously, harvest an equivalent volume of spent CM from the bioreactor, passing it through the TFF module. c. The TFF cassette retains cells and large debris, returning them to the bioreactor (retentate), while the clarified CM (permeate) is collected cold. d. Maintain system parameters (transmembrane pressure, shear rate) within validated ranges to preserve EV integrity.

- Collection: Pool the clarified permeate from the collection bag at defined intervals for downstream processing.

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item | Function in CM Harvest/Clarification |

|---|---|

| EV-Depleted Fetal Bovine Serum (FBS) | Provides growth factors during expansion while minimizing contaminating bovine EVs. Must be ultracentrifuged or commercially sourced. |

| Defined, Serum-Free, Xeno-Free Media | Eliminates animal components entirely for GMP-compliant production, reducing immunogenicity risks. |

| Single-Use, Closed Fluid Transfer Systems | Maintains sterility, reduces adventitious agent risk, and is essential for current GMP. |

| Pre-filtration Membranes (5 µm, 0.8 µm) | Used in series for gentle removal of larger particulates prior to ultrafiltration. |

| Benchtop & Floor Model Centrifuges with CHC | For low-speed clarification; refrigerated chambers with contained heating centrifuges (CHC) protect the operator. |

| Protease & Phosphatase Inhibitor Cocktails | Added to chilled CM immediately post-harvest to preserve EV cargo integrity. |

| Bioreactor with Perfusion Capability | Allows for continuous media exchange and harvest, maximizing cell health and volumetric EV yield. |

| Online pH/DO/Glucose/Lactate Sensors | Monitor conditioning media health to determine optimal harvest windows and ensure process consistency. |

Visualizations

Workflow for Scalable MSC-EV Conditioned Media Collection

Clarification Methods and Target Contaminant Removal

Application Notes: Purification Strategies for GMP-Compliant MSC-EV Production

The transition from research-scale to clinical-grade mesenchymal stromal cell-derived extracellular vesicle (MSC-EV) production necessitates stringent purification protocols compliant with Good Manufacturing Practice (GMP) standards. The primary goal is to isolate EVs with high yield, purity, and potency while removing contaminants like soluble proteins, lipoproteins, and cell debris. This note evaluates three core techniques within a GMP framework.

Tangential Flow Filtration (TFF) is favored for its scalability and closed-system potential, crucial for GMP. It efficiently concentrates and diafiltrates large-volume conditioned media, enabling buffer exchange into formulation buffers. Size-Exclusion Chromatography (SEC) is the gold standard for high-purity EV isolation post-concentration. It effectively separates EVs from co-isolated soluble proteins based on hydrodynamic radius, preserving vesicle integrity and biological activity. Ultracentrifugation (UC) Alternatives address UC's limitations: low scalability, potential vesicle damage, and co-precipitation of contaminants. Alternatives like TFF and SEC are more suitable for reproducible, large-scale GMP processes.

Comparative Performance Data: The following table summarizes key quantitative metrics for each method, derived from recent comparative studies in MSC-EV purification.

Table 1: Comparative Analysis of EV Purification Methods for MSC-EVs

| Parameter | Ultracentrifugation (UC) | Tangential Flow Filtration (TFF) | Size-Exclusion Chromatography (SEC) |

|---|---|---|---|

| EV Yield | Moderate to Low (10-25%) | High (>80%) | Moderate (50-70%) |

| Protein Contamination | High (Protein:EV ratio >100) | Moderate (Protein:EV ratio ~50) | Low (Protein:EV ratio ~20) |

| Lipoprotein Removal | Poor | Moderate | Good (with optimized columns) |

| Process Time | Long (6-24 hours) | Medium (2-5 hours) | Fast (1-2 hours) |

| Scalability | Poor | Excellent | Good (for pilot scale) |

| GMP Compliance Potential | Low (open system, hard to validate) | High (closed system, scalable) | High (reproducible, validated columns) |

| EV Integrity/Function | Often compromised | Well-preserved | Best preserved |

Detailed Experimental Protocols

Protocol 1: Two-Step TFF-SEC for GMP-Grade MSC-EV Purification

This protocol describes a scalable, closed-system workflow for purifying MSC-EVs from conditioned media.

Research Reagent Solutions & Essential Materials: Table 2: Key Reagent Solutions for TFF-SEC Protocol

| Item | Function |

|---|---|

| Serum-free, chemically-defined MSC media | Cell culture medium to produce EV-containing conditioned media without serum-derived contaminants. |

| 0.1 μm PES TFF Cassette | For initial clarification and removal of large debris and apoptotic bodies. |

| 500 kDa MWCO PES TFF Cassette | For concentration and diafiltration of clarified conditioned media to retain EVs. |

| Diafiltration Buffer (e.g., PBS, 0.22 μm filtered) | For buffer exchange into a physiologically compatible solution. |

| qEVoriginal / 70 nm SEC Columns (Izon Science) | For high-resolution separation of EVs from soluble proteins. |

| EV Storage Buffer (e.g., PBS with 1% HSA) | For stabilizing purified EVs post-isolation. |

| 0.22 μm PES Sterile Filters | For terminal sterilization of buffers and final EV product (if applicable). |

Methodology:

- Conditioned Media Harvest: Culture MSCs to 80% confluence in T-flasks or bioreactors. Replace with serum-free media. Collect conditioned media after 48 hours. Centrifuge at 2,000 x g for 30 min at 4°C to remove cells.

- Initial Clarification (TFF): Assemble a 0.1 μm pore size TFF system per manufacturer instructions. Pump the 2,000 x g supernatant through the system in concentration mode until volume is reduced by 50%. Perform diafiltration with 5 volumes of cold PBS.

- EV Concentration & Buffer Exchange (TFF): Switch the retentate to a 500 kDa Molecular Weight Cut-Off (MWCO) TFF cassette. Concentrate the sample to ~1-2 mL. Perform diafiltration with 10 volumes of cold, sterile PBS.

- High-Resolution Purification (SEC): Equilibrate a qEVoriginal column with 20 mL of filtered PBS. Load the concentrated TFF retentate (≤ 1% of column volume). Collect 0.5 mL fractions. EVs typically elute in fractions 7-9 (determined empirically via nanoparticle tracking analysis).

- Concentration & Sterilization: Pool EV-rich SEC fractions. Concentrate using a 100 kDa MWCO centrifugal concentrator if needed. Pass through a 0.22 μm sterile filter for sterilization (validating filter does not retain EVs). Aliquot and store at -80°C.

Protocol 2: Size-Exclusion Chromatography (SEC) Optimization for MSC-EVs

Methodology:

- Column Preparation: Pack a glass column (e.g., 10 x 300 mm) with Sepharose CL-2B or Sephacryl S-400 resin. Equilibrate with 50 mL of 0.22 μm-filtered PBS or 0.9% NaCl.

- Sample Preparation: Pre-concentrate conditioned media (from Protocol 1, Step 1) using a 100 kDa MWCO centrifugal device to a volume of ≤ 500 μL.

- Fractionation: Carefully load the sample onto the column. Elute with PBS at a flow rate of 0.5 mL/min. Collect 0.5 mL fractions automatically.